Method for improving electrolytic current efficiency, metal electrowinning method, and metal electrowinning device

A technology of electrolysis current and efficiency, applied in the direction of process efficiency improvement, electrolysis components, electrolysis process, etc., can solve the problem of low cathode current efficiency, achieve the effect of improving cathode current efficiency, low energy consumption, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

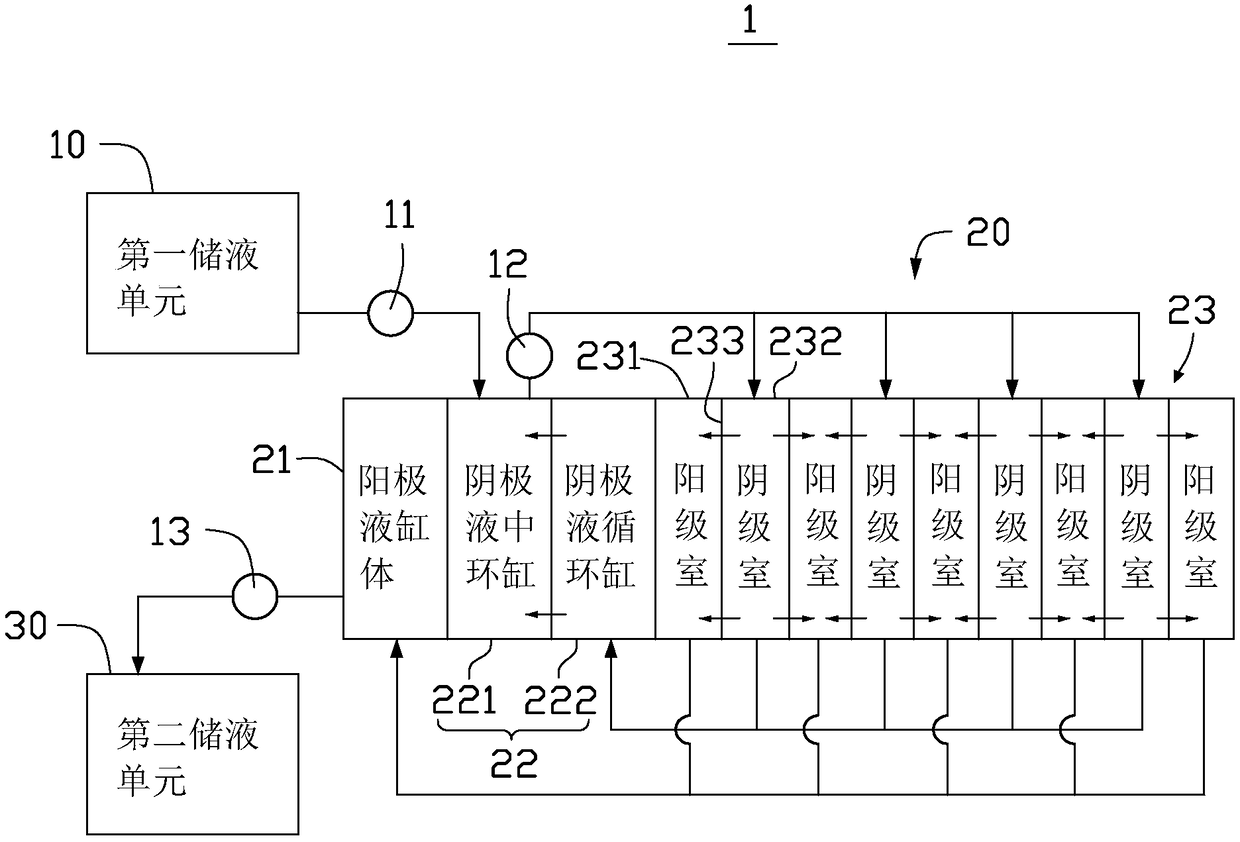

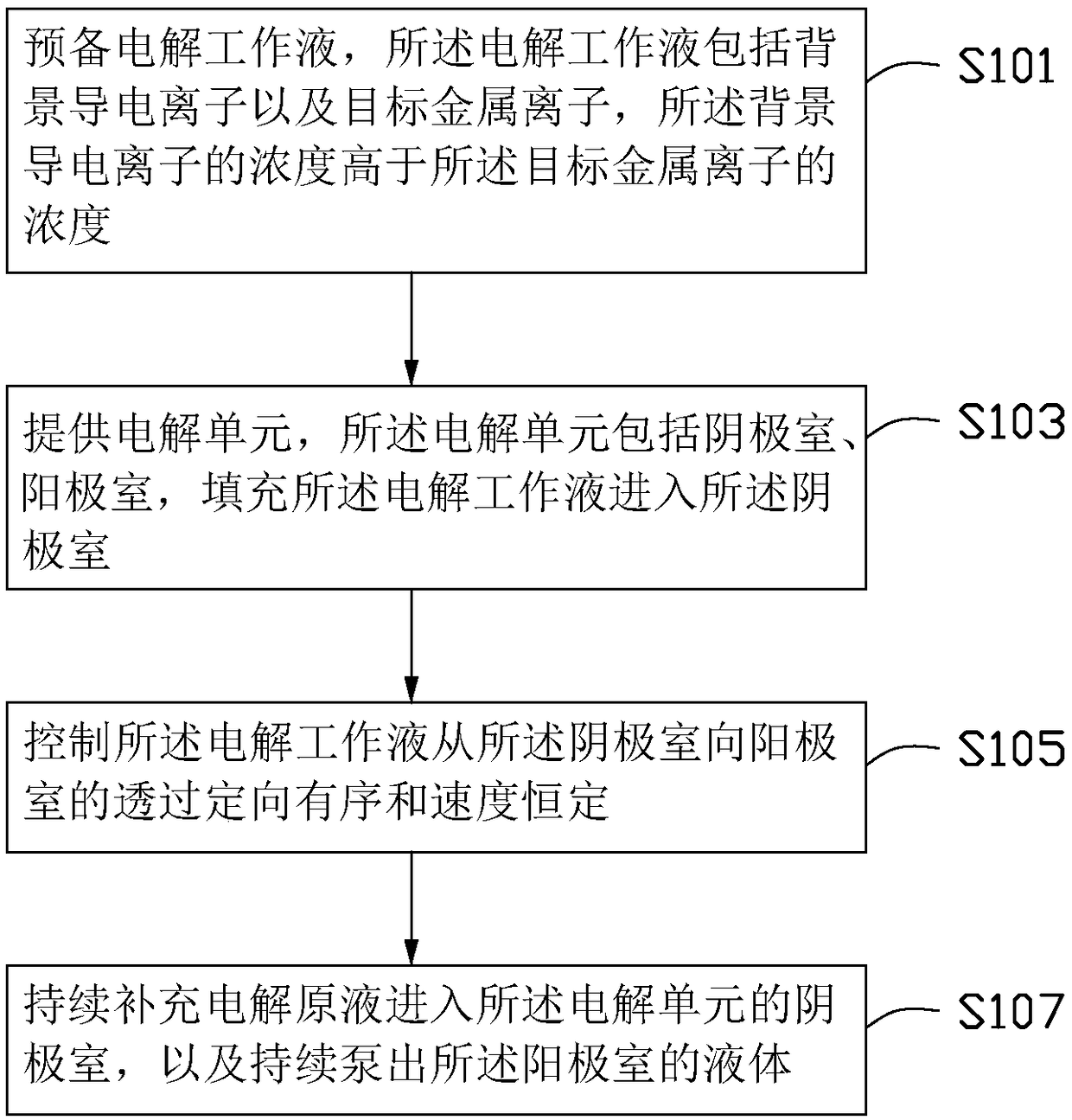

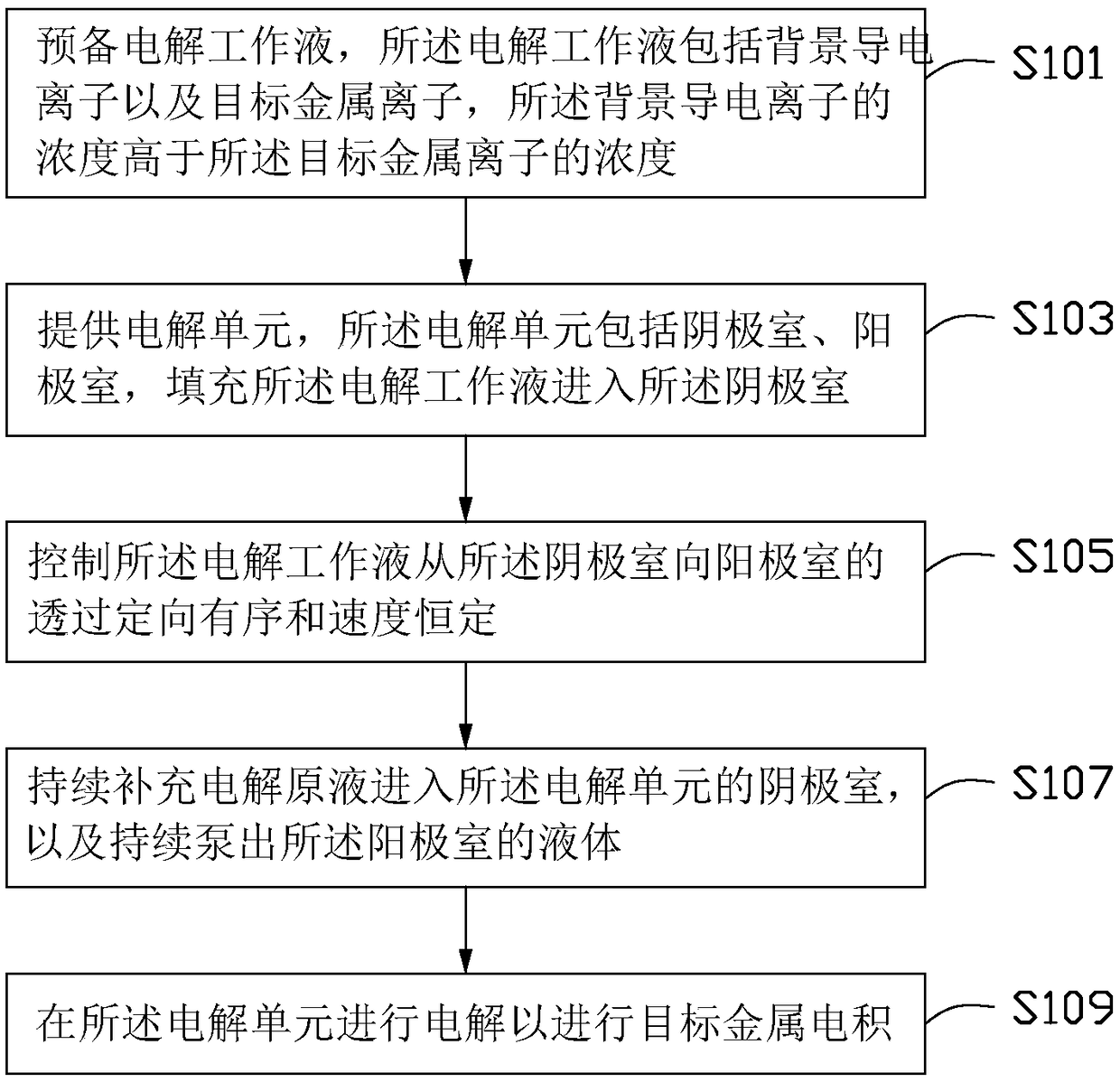

Method used

Image

Examples

no. 1 approach

[0039] The metal electrowinning in this embodiment is copper electrowinning, that is, copper is extracted by electrowinning, and it is equipped with 10L copper chloride electrolytic working solution. The components and contents are as follows: copper chloride 2mol / L; hydrochloric acid 2mol / L; sodium chloride 2mol / L. Take 250mL of the above-mentioned electrolytic working solution, dilute it to 1L with a background salt solution containing 2mol / L hydrochloric acid and 2mol / L sodium chloride as the working electrolytic solution, and reduce the concentration of copper chloride to 0.5mol / L. Take this 1L electrolytic working solution to fill the cathode and anode chambers of the electrolytic cell, and carry out electrolysis of the separator to recover metallic copper. With the titanium plate as the cathode and the iridium-coated tantalum-titanium plate as the anode, the current density is 300A / m 2 , the temperature is 25°C, and the electrodeposition is carried out under the conditi...

no. 2 approach

[0041] The metal electrowinning of this embodiment is ferroelectrowinning, that is, iron is extracted by electrowinning, and it is equipped with 10L ferric chloride electrolytic working solution, and the components and contents are as follows: ferric chloride 2mol / L; hydrochloric acid 1mol / L; chlorine Sodium chloride 2mol / L; take 200mL of the above electrolytic working solution, dilute it to 1L with a background salt solution containing hydrochloric acid 1mol / L; sodium chloride 2mol / L as the electrolytic working solution, and reduce the concentration of ferric chloride to 0.4mol / L . Take this 1L electrolytic working solution to fill the anode and cathode chambers of the electrolytic cell, and carry out electrolysis of the separator to recover metallic iron. With titanium plate as cathode and iridium-coated tantalum titanium plate as anode, the current density is 250A / m 2 , the temperature is 30°C, and the electrodeposition is carried out under the conditions of 5cm different ...

no. 3 approach

[0043] The metal electrowinning in this embodiment is tin electrowinning, that is, tin is extracted by electrowinning, and it is equipped with 10L tin tetrachloride electrolytic working solution. The components and contents are as follows: tin tetrachloride 0.8mol / L; hydrochloric acid 4mol / L; Sodium chloride 2mol / L; Take 250mL of the above-mentioned electrolytic working solution, dilute it to 1L with a background salt solution containing hydrochloric acid 4mol / L; L. Take this 1L electrolytic working solution to fill the anode and cathode chambers of the electrolytic cell, and carry out electrolysis of the separator to recover metallic iron. With titanium plate as cathode and iridium-coated tantalum titanium plate as anode, the current density is 350A / m 2 , the temperature is 30°C, and the electrodeposition is carried out under the conditions of 5cm different pole distance, the total effective area of the cathode is 0.016m 2 . Observe the precipitation of tin on the cathod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com