Corrosion resisting solar backplane structure

A solar back sheet, corrosion-resistant technology, applied in the field of solar back sheets, can solve the problems of unstable performance, affecting the service life of solar cell back sheets, easy to corrode, etc., and achieves good environmental protection performance, excellent anti-aging performance, and high weather resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

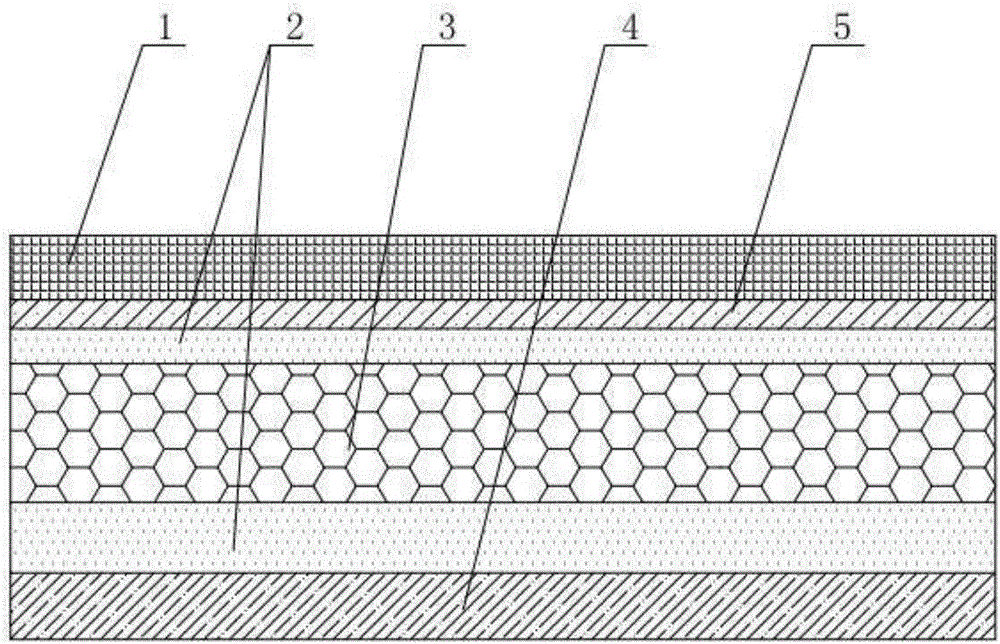

[0017] A corrosion-resistant solar backsheet structure includes a PET base material 3, a high-temperature corrosion-resistant coating 5 is bonded to one side of the PET base material 3 through an adhesive layer 2, and a weather-resistant layer 1 is bonded to the surface of the weather-resistant layer 1. The PET base material The other side of the material 3 is bonded to the weather-resistant adhesive layer 4 through the adhesive layer 2. The high-temperature corrosion-resistant coating is made of epoxy resin composite material, and the thickness of the high-temperature corrosion-resistant coating 5 is 0.1-1 μm. The thickness of the PET substrate 3 is 80-400 microns, the thickness of the adhesive layer 2 is 0.5-40 microns, and the thickness of the weather-resistant adhesive layer 4 is 40-60 microns.

[0018] The material of the weather-resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com