Synthetic method of micromolecule pickling auxiliary tanning agent

A synthesis method and technology of a tanning aid are applied in the field of synthesizing a small-molecule pickling aid, which can solve the problems of limited reduction of neutral salts, increasing cross-linking sites of chrome tanning, and inability to solve the problems of salts used for pickling, etc. Achieve high absorption and reduce elution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

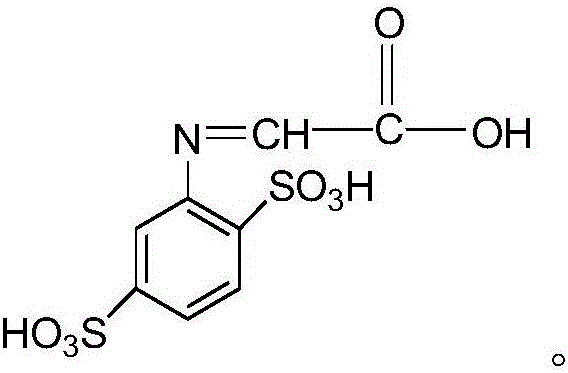

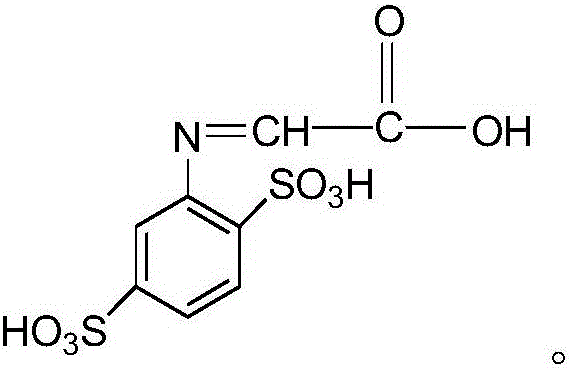

[0018] A kind of synthetic method of small molecule pickling auxiliary tanning agent, comprises the following steps:

[0019] Add 28.9 parts of aniline-2,5-disulfonic acid and 21.1 parts of glyoxylic acid into a reactor equipped with a stirrer, a thermometer, and a reflux condenser. After stirring at room temperature, adjust the pH of the system to 4.0, raise the system temperature to 95°C, react for 6 hours, cool down to room temperature, add 20 parts of distilled water, adjust the solid content of the system to 50%, and obtain a small molecule pickling auxiliary tanning agent, the parts are parts by mass.

Embodiment 2

[0021] A kind of synthetic method of small molecule pickling auxiliary tanning agent, comprises the following steps:

[0022] Add 57.7 parts of aniline-2,5-disulfonic acid and 42.3 parts of glyoxylic acid into a reactor equipped with a stirrer, a thermometer, and a reflux condenser. After stirring at room temperature, adjust the pH of the system to 4.5 with triethylamine. Raise the temperature of the system to 90°C, react for 6 hours, cool down to room temperature, add 40 parts of distilled water, adjust the solid content of the system to 50%, and obtain a small-molecule pickling auxiliary tanning agent, and the stated parts are parts by mass.

Embodiment 3

[0024] A kind of synthetic method of small molecule pickling auxiliary tanning agent, comprises the following steps:

[0025] Add 86.6 parts of aniline-2,5-disulfonic acid and 63.4 parts of glyoxylic acid into a reactor equipped with a stirrer, a thermometer, and a reflux condenser. After stirring at room temperature, adjust the pH of the system to 5.0 with KOH solution. The high system temperature is 100°C, react for 6 hours, cool down to room temperature, add 60 parts of distilled water, adjust the solid content of the system to 50%, and obtain a small-molecule pickling auxiliary tanning agent, and the stated parts are parts by mass.

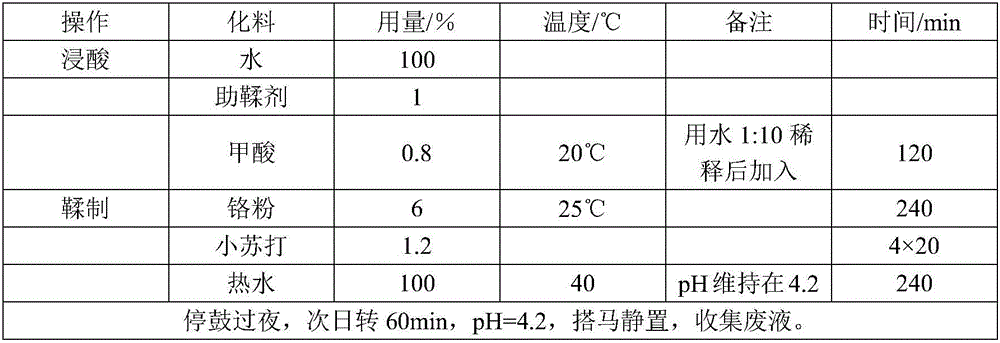

[0026] Application of pickling auxiliary tanning agent: Yellow cowhide is used for tanning experiments after conventional soaking, dehairing, liming, fleshing, deliming and softening. The leather thickness is 2.3-2.5cm. The specific salt-free pickling process is shown in Table 1, and the sensory evaluation results of tanning waste liquor and w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com