A Mushroom Nutrient Covering Soil Using Mushrooms to Produce Wasteland

A technology of nutrient soil and mushroom waste, applied in the field of edible fungus cultivation, can solve the problems of no direct use value, excessive heavy metal content, heavy disinfection workload, etc., achieve environmental protection, pesticide residues, high saturated water content, and avoid miscellaneous bacteria Effect of infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

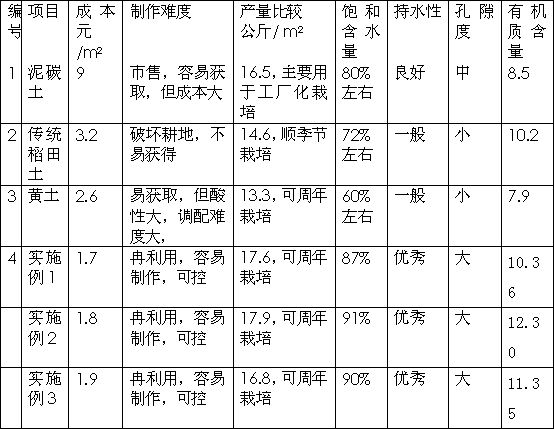

Examples

preparation example Construction

[0031]The fermentation sludge is prepared from the following method: a volume ratio of 5-6: 1-2, a living sludge and a cereal, mixed and mixed for 1-2 days;

[0032]When the water content is 55-65%, the laminated life sludge after mixing and stalls is fed to the fermentation tank, which is 1.2-1.5 meters, and the width is 1.0-1.2 meters. After the heap fermentation of 7-10 days, the groove fermentation was 3-4 times, and the heap fermentation time and the height and width of the bunting heap height and the width after the groove were the same as the previous.

[0033]When the water content is reduced to 40% -45% and the amount of nitrogen in the sludge is reduced to 0.28-0.4%, the ammonia flavor is substantially disappeared, and then use.

[0034]The moisture content of the living sludge is 85%.

[0035]The mushroom nutrients are prepared according to the following methods: Take the rice to take the rice, the mushroom is special rice field nutritious soil, remove the roots of the straw, and the...

Embodiment 1

[0038]A mushroom nutrients that utilize mushroom waste soil, the nutrient-raised formula is mainly composed of mushroom special rice field nutrition soil, lime, water and fungicide;

[0039]Among them, the mushroom special rice field nutrient soil is mainly prepared by 2000 parts by mass of fermentation sludge and 10000 parts by mass of mushroom production waste.

[0040]The mushroom special rice field nutrient soil is prepared according to the following method: the 2000 parts by mass of the mushroom is mixed, and the production of waste soil is mixed, and the water field is completed, then add 2000 parts by mass of the stack. Water, when the water is completely absorbed, the stacks in the flat field are horizontally positioned, while maintaining the water level of the water field is 3 cm, then the transplant is planted in rice, until rice harvesting, and retains 4 rice fields after rice Many months have enabled the roots of the straw after anaerobic fermentation, that is, the mushroom sp...

Embodiment 2

[0050]A mushroom nutrients that utilize mushroom waste soil, the nutrient-raised formula is mainly composed of mushroom special rice field nutrition soil, lime, water and fungicide;

[0051]Among them, the mushroom special rice field nutrient soil is mainly made of 2500 parts by mass of fermentation sludge and 11,000 parts by mass of mushroom production waste by fermentation.

[0052]The mushroom special rice field nutrition soil is mainly prepared according to the following methods: the 2500 parts by mass of the parameters and the production of waste soil are mixed, and the water field is completed, then add 3,000 parts by mass of the stack. Water, when the water is completely absorbed, the stacks in the flat field are horizontally positioned, while maintaining the water level of the water field is 4 cm, then the transplant is planted in rice, until rice harvesting, and retains 4 rice fields after rice Many months have enabled the roots of the straw after anaerobic fermentation, that is,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com