Energy-saving and environment-friendly potato flour processing method

A potato powder and processing method technology, which is applied in the agricultural field, can solve the problems of high energy consumption, difficult solid-liquid separation, and high water content of potato powder, and achieve the goal of reducing investment in environmental protection equipment, reducing production costs, and reducing drying energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

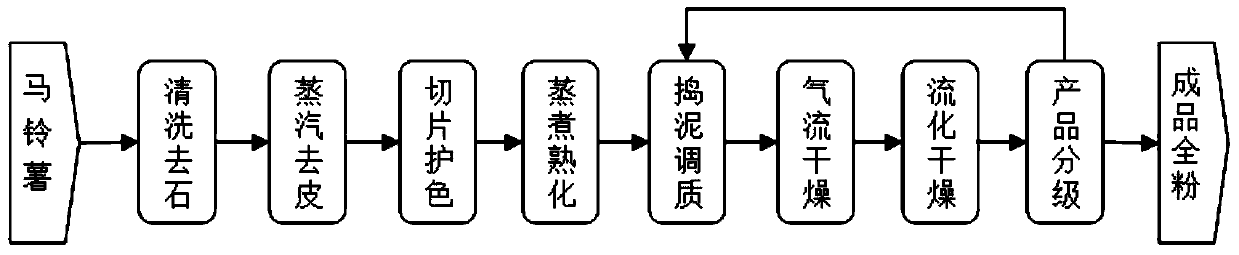

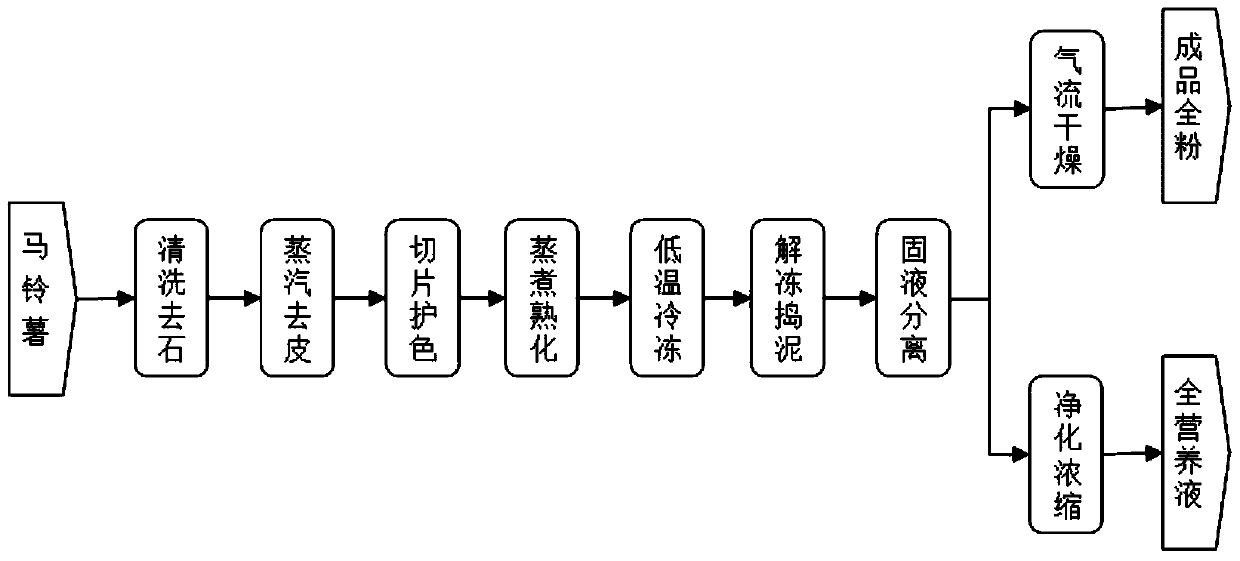

[0028] The energy-saving and environment-friendly potato whole flour processing method of the present embodiment is carried out according to the following steps:

[0029] 1. Cleaning of raw materials: The potatoes are rolled and cleaned under the drive of the water flow to remove most of the soil and sundries bonded to the surface, and then enter the stone separator to remove the sand and gravel, and then enter the multi-stage horizontal washing machine for further cleaning to remove the sediment , to cleanse the potatoes;

[0030] 2. Steam peeling: Send the potatoes cleaned in step 1 into the cooking tank regularly and quantitatively with a conveyor and a metering device, and cook them quickly in medium-pressure steam (1.6-4.0MPa) until the potato skins are matured. Potato skin expands rapidly, detaches from the parent body, and is in a state of falling off or sticking; the steamed potatoes are transported into the dry skin brushing machine with a screw conveyor, and the pota...

Embodiment 2

[0039] The energy-saving and environment-friendly potato whole flour processing method of the present embodiment is carried out according to the following steps:

[0040] 1. Cleaning of raw materials: The potatoes are rolled and cleaned under the drive of the water flow to remove most of the soil and sundries bonded to the surface, and then enter the stone separator to remove the sand and gravel, and then enter the multi-stage horizontal washing machine for further cleaning to remove the sediment , to cleanse the potatoes;

[0041] 2. Steam peeling: Send the potatoes cleaned in step 1 into the cooking tank regularly and quantitatively with a conveyor and a metering device, and cook them quickly in medium-pressure steam (1.6-4.0MPa) until the potato skins are matured. Potato skin expands rapidly, detaches from the parent body, and is in a state of falling off or sticking; the steamed potatoes are transported into the dry skin brushing machine with a screw conveyor, and the pota...

Embodiment 3

[0050] The energy-saving and environment-friendly potato whole flour processing method of the present embodiment is carried out according to the following steps:

[0051] 1. Cleaning of raw materials: The potatoes are rolled and cleaned under the drive of the water flow to remove most of the soil and sundries bonded to the surface, and then enter the stone separator to remove the sand and gravel, and then enter the multi-stage horizontal washing machine for further cleaning to remove the sediment , to cleanse the potatoes;

[0052] 2. Steam peeling: Send the potatoes cleaned in step 1 into the cooking tank regularly and quantitatively with a conveyor and a metering device, and cook them quickly in medium-pressure steam (1.6-4.0MPa) until the potato skins are matured. Potato skin expands rapidly, detaches from the parent body, and is in a state of falling off or sticking; the steamed potatoes are transported into the dry skin brushing machine with a screw conveyor, and the pota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com