High-efficiency environment-friendly foam extinguishing agent and preparation method thereof

A foam fire extinguishing agent, an environment-friendly technology, applied to fire prevention equipment, etc., can solve the problems of no research and reports on environment-friendly aqueous film-forming foam fire extinguishing agents, and achieve the effects of excellent fire extinguishing performance, high production efficiency, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

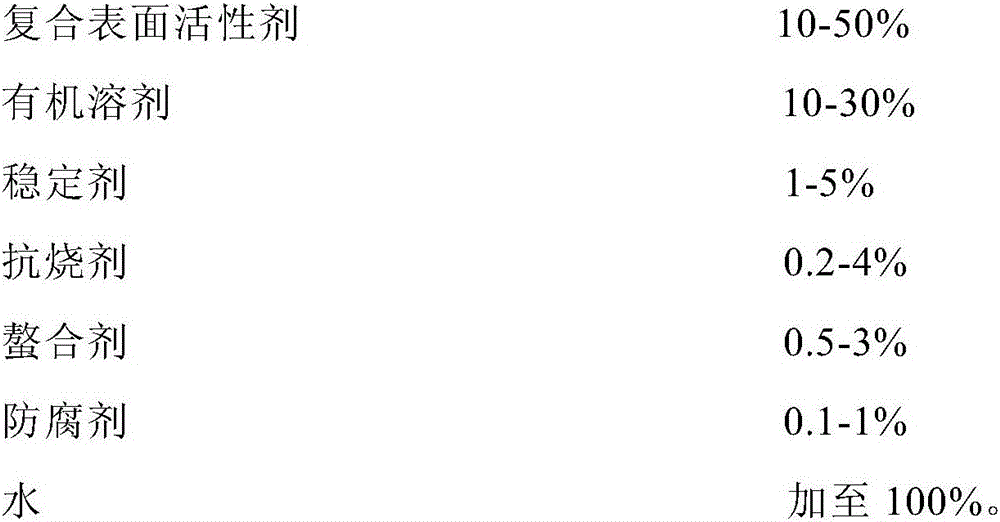

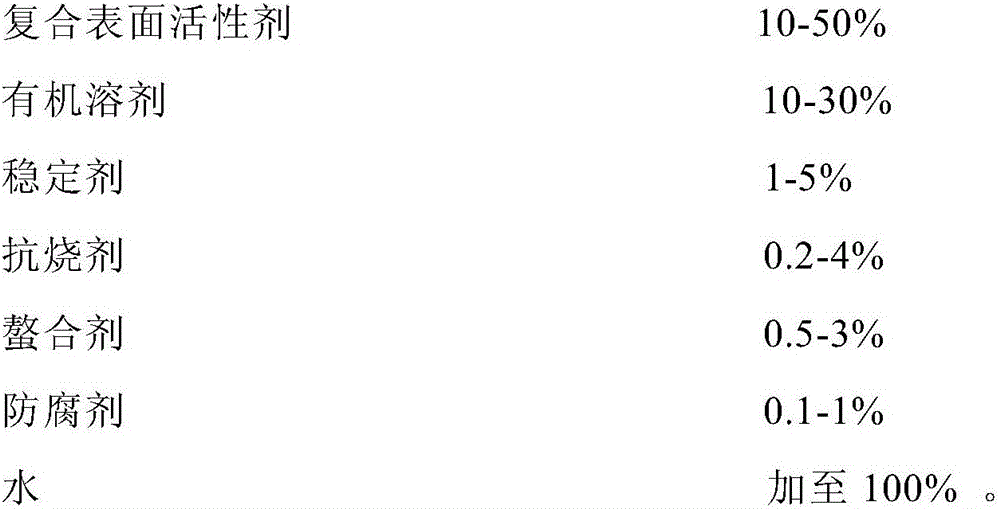

Method used

Image

Examples

Embodiment 1

[0030] Weigh 4kg of organosilicon sulfate surfactant, 2kg of non-ionic polyether modified silicone oil surfactant, 10kg of SDS, 20kg of BS-12, and 5kg of lauryl polyoxyethylene ether Brij30 into 25kg of water in turn to form the components A, stir well; at the same time weigh 5kg of diethylene glycol monobutyl ether, 15kg of ethylene glycol, 2kg of dodecanol, 1kg of n-octanol, and 1kg of n-nonanol to form component B. After fully stirring, add A to the continuous In the stirring B, continue to stir; weigh 3kg of urea, 0.3kg of xanthan gum, 0.5kg of EDTA, and 0.3kg of sodium benzoate into the AB mixing system in turn, add water to 100kg, and stir evenly.

Embodiment 2

[0032] Weigh respectively 8kg of organosilicon sulfonate, 15kg of SDBS, 15kg of amphoteric imidazoline, and 2kg of isotridecyl alcohol polyoxyethylene ether into 25kg of water in turn to form component A, and stir thoroughly; at the same time, weigh diethylene glycol mono 3kg of butyl ether, 5kg of diethylene glycol ethyl ether, 10kg of ethylene glycol, 2kg of propylene glycol, and 3kg of dodecyl alcohol form component B. After fully stirring, add A to the continuously stirring B and continue stirring; weigh 3kg of urea, Add 0.2kg of xanthan gum, 0.6kg of EATD disodium, and 0.5kg of potassium sorbate into the AB mixing system in turn, add water to 100kg, and stir evenly.

Embodiment 3

[0034] Weigh respectively 3kg of silicone sulfate surfactant, 3kg of silicone sulfonate surfactant, 1kg of nonionic polyether modified silicone oil, 12kg of SDS, 15kg of amphoteric imidazoline, and 3kg of polyoxyethylene lauryl ether Brij35 into In 25kg of water, compose component A and stir thoroughly; simultaneously weigh 10kg of ethylene glycol, 10kg of diethylene glycol monobutyl ether, 1kg of dodecyl alcohol, and 1kg of n-octanol to compose component B, after fully stirring; A and B respectively After fully stirring, add A to the continuously stirring B, and continue stirring; weigh 3kg of urea, 0.6kg of sodium hydroxymethylcellulose, 0.2kg of EDTA, and 0.3kg of sodium benzoate into the AB mixing system in turn, and add water to 100kg , stir evenly.

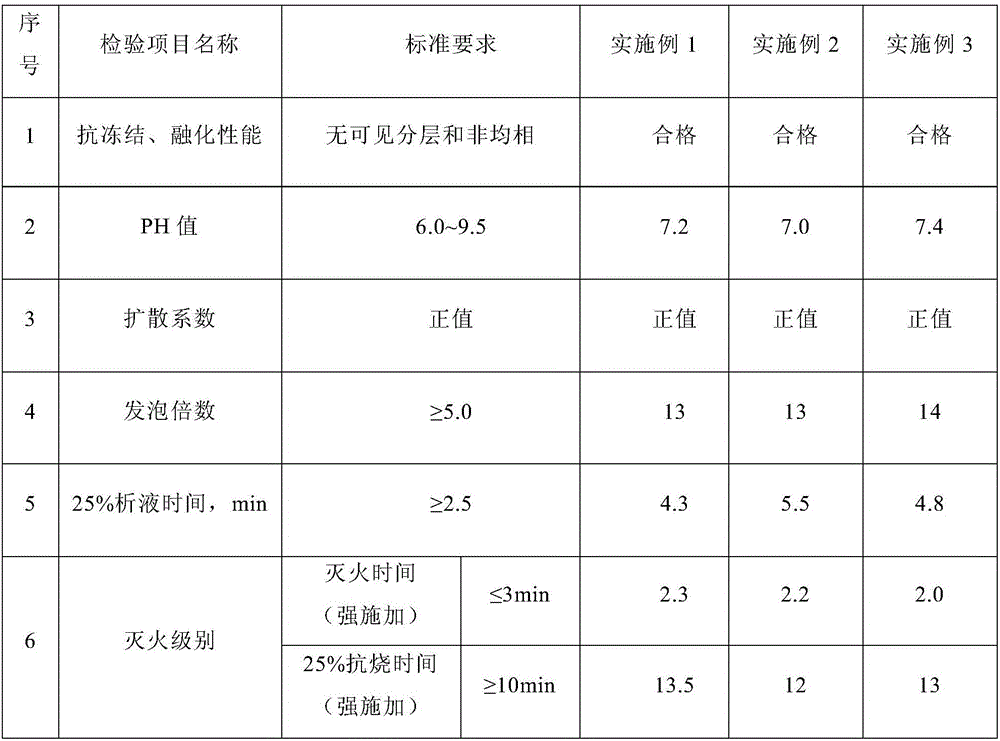

[0035] The physical and chemical properties and fire extinguishing properties of the solution prepared by mixing the products of the above Examples 1-3 with water at a ratio of 3:97 by volume all meet the requirements of GB1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com