Method for preparing nitrogen and phosphorus removal adsorbent from sludge of water plant

A technology for denitrification and phosphorus removal, adsorbent, applied in water/sludge/sewage treatment, water/sewage treatment, chemical instruments and methods, etc. Simple, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

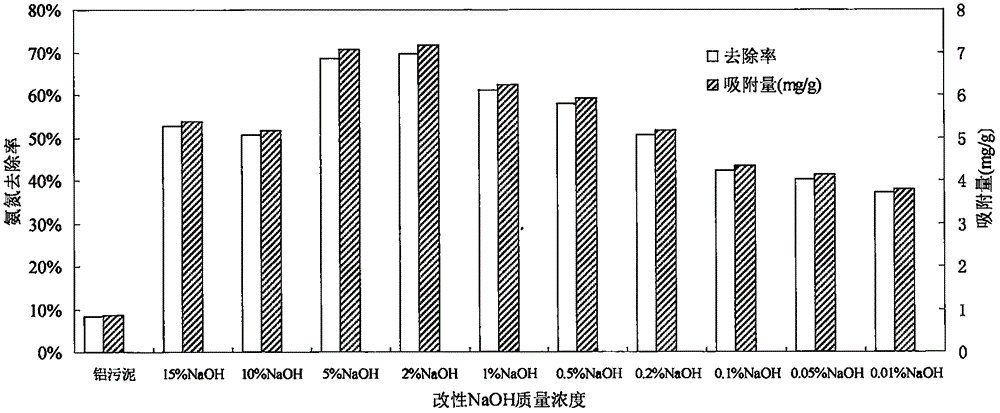

[0035] Optimization experiment of different modification methods

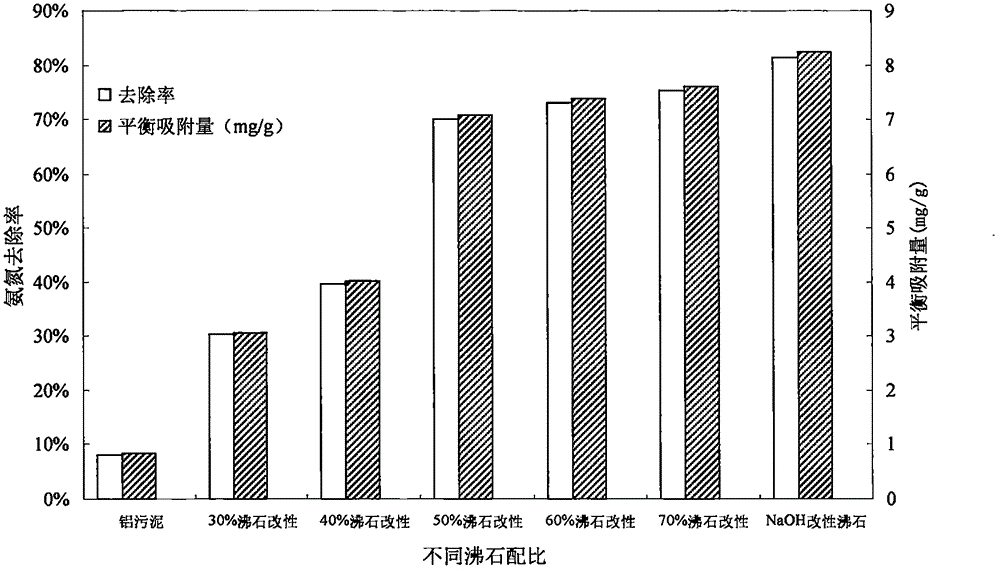

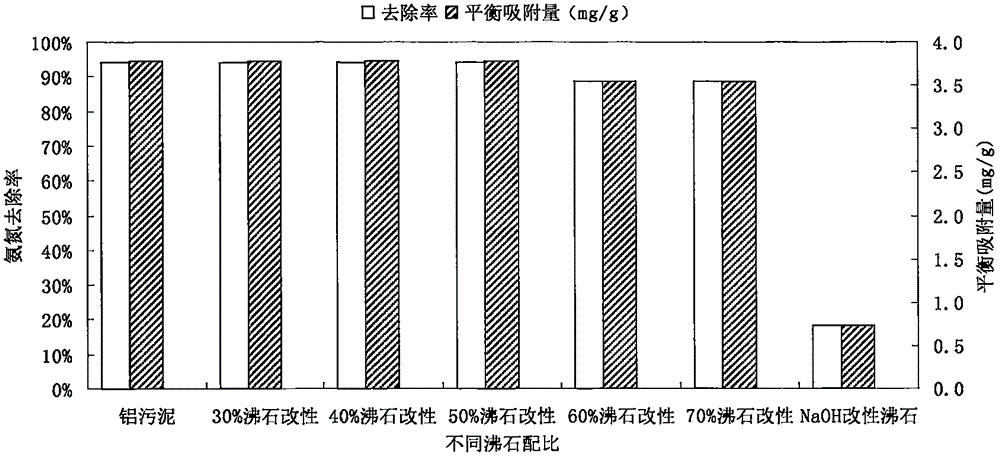

[0036] (1) Effect of mixed modification (zeolite ratio) on the adsorption effect of nitrogen and phosphorus

[0037] Use former sludge, zeolite ratio is 30%, 40%, 50%, 60%, 70% zeolite aluminum sludge and zeolite, alkali modification and high temperature modification specific steps are as described in four (2,3), The obtained adsorbent is carried out nitrogen and phosphorus adsorption test. The specific method is to weigh 1 g of each of the above adsorbents respectively, and add them to 200 mL of 250 mL of water samples with an initial phosphorus concentration of 20 mg / L and an initial ammonia nitrogen concentration of 50 mg / L. shaped bottle. Shake at 120rpm and the temperature is (25±1)°C for 120h, measure the concentration of residual ammonia nitrogen and phosphorus adsorbed every 12h, calculate the removal rate and adsorption amount of ammonia nitrogen and phosphate, and obtain the results as follows figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com