A kind of preparation method of nano cuprous oxide hollow sphere

A technology of nano-cuprous oxide and hollow spheres, which is applied in the synthesis of cuprous oxide and the direct synthesis of cuprous oxide nanomaterials, which can solve the problems of large particle size and long reaction time, and achieve short reaction time and uniform shape distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Take 68mL of 0.01M copper sulfate solution, add 0.5g of polyvinylpyrrolidone, and keep the water bath at room temperature to react; Add 68mL, 0.05M ascorbic acid solution, stir for 30min, wash 3 times with deionized water, wash 3 times with absolute ethanol, and then put it in a vacuum oven for 4h at 60°C to form a cuprous oxide hollow ball.

[0034] In the technical solution of the present invention, the copper salt and the complexing agent can form a copper complex, and the copper complex has an analytical equilibrium. With the addition of the reducing agent, the balance is destroyed, and cuprous oxide is gradually and slowly formed. . Present embodiment is main raw material with copper sulfate, ammoniacal liquor, and its chemical reaction formula is as follows:

[0035]

[0036]

[0037] .

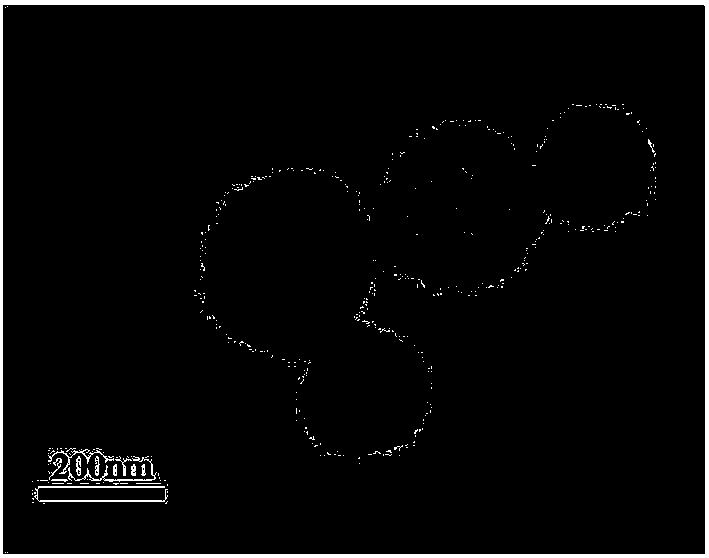

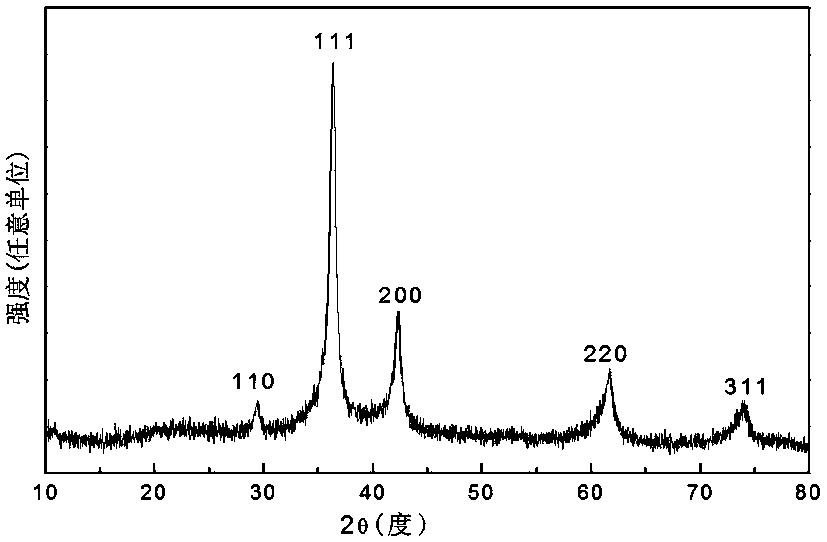

[0038] The morphology and structure of cuprous oxide are hollow spheres. The samples were analyzed and characterized by scanning electron microscope (SEM), X-ray dif...

Embodiment 2

[0043] Take 68mL of 0.01M copper sulfate solution, add 0.5g sodium lauryl sulfate, and keep the water bath at room temperature for reaction; after fully dissolving, add dropwise 16mL of ammonia solution diluted at a volume ratio of 1:10, and stir for 10min Finally, add 68mL, 0.05M ascorbic acid solution dropwise, stir for 30min, wash 3 times with deionized water, wash 3 times with absolute ethanol, and then put it in a vacuum oven at 60°C for 4h, which is an oxidation Cuprous. See attached Figure 4 , which is the SEM image of the cuprous oxide prepared in this embodiment.

Embodiment 3

[0045] Take 60mL of 0.01M copper acetate solution, add 4mL of triethanolamine (analytical pure) dropwise, stir for 10min, add 60mL of 0.01M hydrazine hydrate dropwise, stir for 30min, wash with deionized water 3 times, and wash with absolute ethanol 3 times, and then dried in a vacuum oven at 60°C for 4 hours to obtain a cuprous oxide. See attached Figure 5 , which is the SEM image of the cuprous oxide prepared in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com