Wave-blocking concrete block

A technology of concrete and water reducing agent, which is applied in the direction of climate change adaptation, coastline protection, jetty, etc., and can solve the problems of common wave-blocks being not resistant to erosion, not resistant to erosion and durability of salt solution, nickel slag occupying land and polluting the environment, etc. Achieve high resistance to chlorine salt corrosion, strong erosion resistance, and improve construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

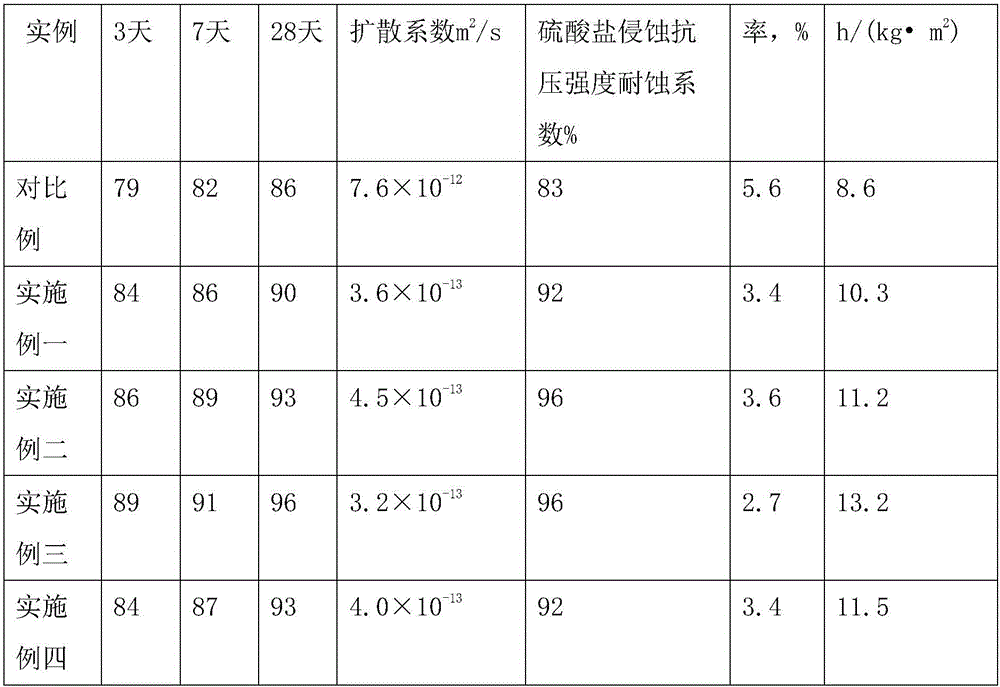

Embodiment 1

[0030] The concrete for the wave block is composed of the following parts by mass: 300 parts of PII 52.5 cement, 80 parts of mineral powder, 100 parts of nickel slag powder, 900 parts of nickel slag aggregate, 900 parts of stone, 145 parts of water, and 4 parts of polycarboxylate superplasticizer 3 parts, 3 parts of sodium hydroxide, 3 parts of sodium silicate, 30 parts of steel fibers with a length of 10 mm and an aspect ratio of 30, 2 parts of sodium stearate, and 5 parts of redispersible latex powder. Apply a layer of two-component water-based polyurethane coating on the concrete surface 28 days after the wave block concrete is poured.

Embodiment 2

[0032] P0 42.5 400 parts of cement, 30 parts of mineral powder, 60 parts of nickel slag powder, 700 parts of nickel slag aggregate, 1100 parts of stone, 135 parts of water, 4 parts of aliphatic water reducer, 1 part of sodium hydroxide, 3 parts of sodium silicate Parts, 20 parts of steel fiber with a length of 50 mm and an aspect ratio of 60, KOCH 2 5 parts of OH, 2 parts of redispersible latex powder. Apply a layer of two-component water-based polyurethane coating on the concrete surface 28 days after the wave block concrete is poured.

Embodiment 3

[0034] 360 parts of PII 52.5 cement, 20 parts of mineral powder, 100 parts of nickel slag powder, 600 parts of nickel slag aggregate, 1200 parts of stone, 135 parts of water, 4 parts of polycarboxylate superplasticizer, 2 parts of sodium hydroxide, sodium silicate 4 parts, 30 parts of steel fiber with a length of 15mm and an aspect ratio of 60, KOCH 2 5 parts of OH, 2 parts of redispersible latex powder. After 28 days of concrete pouring for the wave block, the surface of the concrete is impregnated with γ-glycidyl etheroxypropyl trimethoxysilane solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com