Preparation method of high alumina ceramic material with microcosmic convex-concave and ploughing-type surface structure and product prepared by preparation method

A technology of high-alumina ceramics and surface structure, which is applied in the field of structural ceramics preparation, can solve the problems of easy-to-break yarn quality and decline in spinning, and achieve the effect of facilitating low-temperature sintering and increasing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

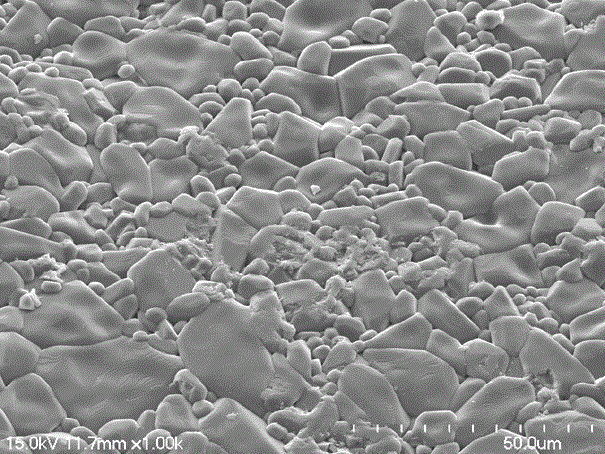

[0025] Preparation of corundum ceramics with microscopic convex-convex and plow-like surface structure

[0026] The first step is the preparation of composite additives: magnesium oxide and potassium sodium feldspar are mixed in a weight ratio of 1:2, mixed evenly, heated to 1350°C to melt, and quenched to D 50 =1µm, dried to obtain composite additive powder;

[0027] The second step, ingredients: aluminum oxide powder (D 50 =1µm) 99wt%, composite additive 1wt%, plus 0.2wt% ammonium polyacrylate, weighed, added 30% water, ball milled and mixed evenly;

[0028] The third step, forming: using gypsum mold for grouting molding to make green body;

[0029] The fourth step, sintering: the green body is fired at 1700°C, and kept at the highest temperature for 30 minutes to obtain corundum ceramics with a water absorption rate of 0.1%;

[0030] The fifth step, surface processing: use diamond grinding wheel to process the surface of corundum ceramics to level 11 smoothness;

[0031...

Embodiment 2

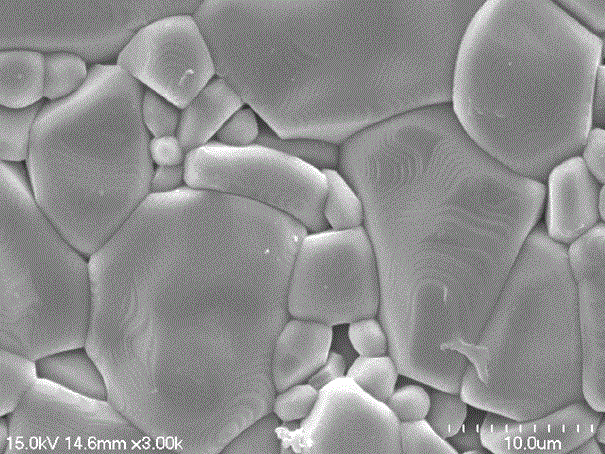

[0034] Preparation of 95% alumina ceramics with micro-convex and plowed surface structure

[0035] The first step is the preparation of composite additives: magnesium oxide and potassium sodium feldspar are mixed in a weight ratio of 1:2, mixed evenly, heated to 1350°C to melt, and quenched to D 50 =1µm, dried to obtain composite additive powder;

[0036] The second step, ingredients: the alumina powder (D 50 =1µm) 94wt%, dried composite additive 6wt%, plus 0.3wt% oleic acid, weighed, dry ball milled and mixed for 6 hours, took it out and baked it at 110°C for 2 hours to obtain hot powder;

[0037] The third step, mixing wax: take 56°paraffin wax with a weight of 15wt% of the hot powder, melt it evenly in an aluminum bucket at 80°C, add the hot powder obtained in the second step while stirring, gradually add the hot powder, and add the hot powder to three After two-half, add 0.1wt% oleic acid, mix the hot powder and paraffin evenly, and get rid of the air bubbles in the wax ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com