Weld seam heat treatment method of steel for 700 MPa-grade automobile torsion beam

A heat treatment method and torsion beam technology, applied in heat treatment furnaces, heat treatment equipment, process efficiency improvement, etc., can solve the problems of easy cracking of automobile torsion beams and low fatigue life of finished automobile torsion beams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Embodiment 1 provides a kind of heat treatment method of 700MPa class automobile torsion beam steel weld seam, welded steel pipe is 700MPa class high-frequency welded pipe, steel pipe wall thickness is 2mm, weld seam width is 2mm, steel pipe chemical composition is as shown in Table 1, all the other are Fe and unavoidable impurities. Using intermediate frequency induction heating, the temperature is raised to 800°C in an area with a distance of 8mm from the weld seam, with the weld seam as the axis of symmetry, the first heat preservation is 20s, the cooling rate is controlled at 15°C / s, the air is cooled to 580°C, and the second heat preservation is 25s. Air cool to room temperature.

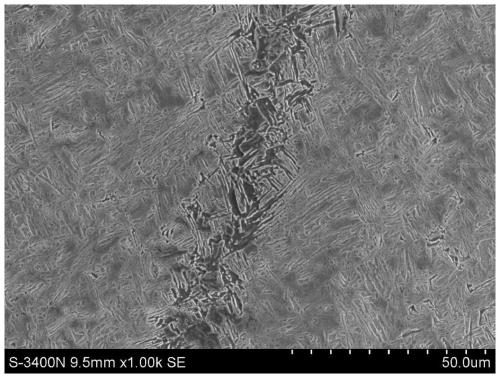

[0061] Observation before heat treatment, the weld center fusion line structure is ferrite + lath bainite structure; weld heat affected zone is martensite + lath bainite structure; base metal structure is granular bainite structure . Weld structure such as figure 1 As shown, the base ...

Embodiment 2

[0065] Embodiment 2 provides a kind of heat treatment method of 700MPa grade automobile torsion beam steel weld seam, welded steel pipe is 700MPa grade high-frequency welded pipe, steel pipe wall thickness is 3mm, weld seam width is 1.5mm, steel pipe chemical composition is as shown in Table 1, the rest For Fe and unavoidable impurities. Using intermediate frequency induction heating, the temperature is raised to 820°C in an area with a distance of 6 mm from the weld seam, with the weld seam as the axis of symmetry, the first heat preservation is 27s, the cooling rate is controlled at 18°C / s, the air is cooled to 560°C, and the second heat preservation is 30s. Air cool to room temperature.

[0066] Observation before heat treatment, the weld center fusion line structure is ferrite + lath bainite structure; weld heat affected zone is martensite + lath bainite structure; base metal structure is granular bainite structure .

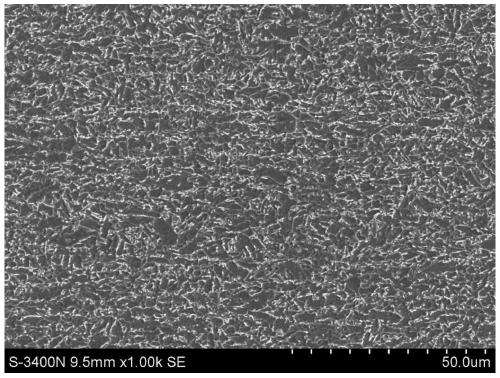

[0067] Observation after heat treatment: the fusion ...

Embodiment 3

[0070] Embodiment 3 provides a kind of heat treatment method of 700MPa grade automobile torsion beam steel weld seam, welded steel pipe is 700MPa grade high-frequency welded pipe, steel pipe wall thickness is 4mm, weld seam width is 2mm, steel pipe chemical composition is as shown in Table 1, all the other are Fe and unavoidable impurities. Medium frequency induction heating is used to heat up to 810°C in an area with a distance of 8mm from the weld seam, with the weld seam as the axis of symmetry. The first heat preservation is 17s, the cooling rate is controlled at 13°C / s, the air cooling is to 560°C, and the second heat preservation is 35s. , after air cooling to 254°C for 1min, water cooling to 25°C at a water cooling rate of 30°C / s.

[0071] Observation before heat treatment, the weld center fusion line structure is ferrite + lath bainite structure; weld heat affected zone is martensite + lath bainite structure; base metal structure is granular bainite structure .

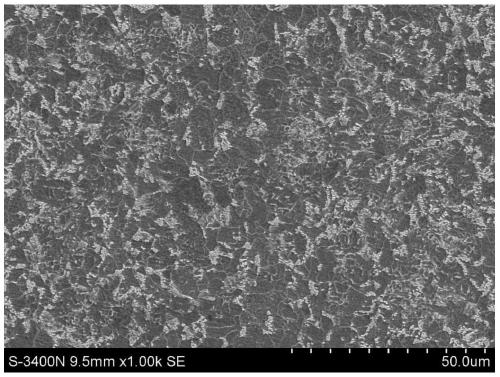

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com