Flame-resistant modified nylon 56 polymer and preparation method thereof

A technology for modifying nylon and polymers, which is applied in the field of flame-retardant modified nylon 56 polymers and its preparation. It can solve the problems of affecting the physical properties of polymers, the addition of large amounts, and the inability to solve the problems of nylon 56 melting and dripping, and achieve high resistance. Flammability, ease of modification and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1, prepare flame-retardant modified nylon 56 polymer

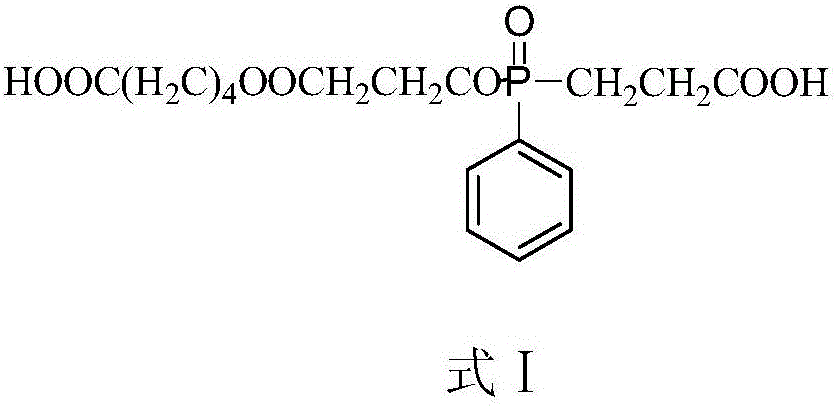

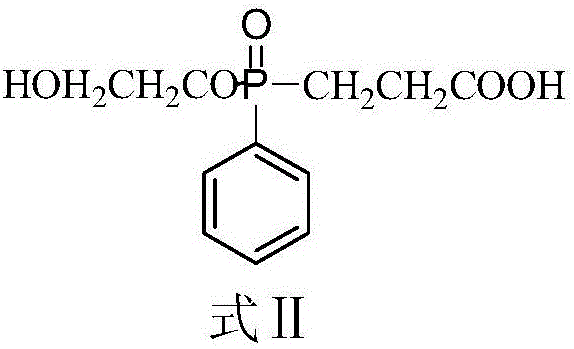

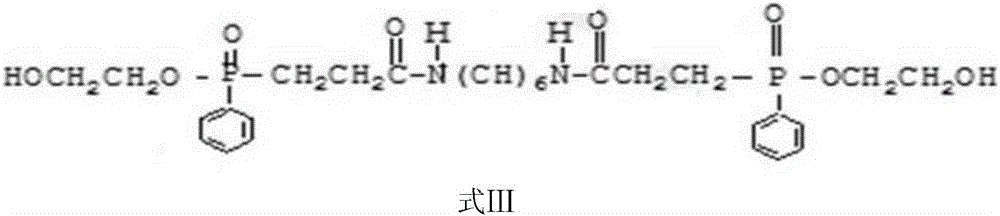

[0055] Under the protection of nitrogen atmosphere, bio-based pentamethylenediamine was dissolved in deionized water, adipic acid was gradually added, and the molar ratio of bio-based pentamethylenediamine to adipic acid was controlled to be 1.05:1, and a mass concentration of 50% was prepared. Nylon 56 salt solution with a pH of 7.2. Prepared nylon 56 saline solution 5kg, the acetic acid solution of bio-based pentamethylenediamine (the mass percentage of bio-based pentamethylenediamine is 24%, its addition is the sum of bio-based pentamethylenediamine and adipic acid added mass 0.07%) 1.75g, flame retardant TL-A2 50g, flame retardant TL-B1 50g (((the amount of flame retardant added is 4% of the sum of the mass of bio-based pentamethylenediamine and adipic acid added)) and modified 125g of permanent melamine cyanurate (the addition amount is 5% of the sum of the mass of bio-based pentamethylenediamine an...

Embodiment 2

[0058] Embodiment 2, prepare flame-retardant modified nylon 56 polymer

[0059] Under the protection of nitrogen atmosphere, bio-based pentamethylenediamine was dissolved in deionized water, adipic acid was gradually added, and the molar ratio of bio-based pentamethylenediamine to adipic acid was controlled to be 1.2:1, and a mass concentration of 60% was prepared. Nylon 56 salt solution with a pH of 7.8. Prepared nylon 56 saline solution 10kg, acetic acid solution of bio-based pentamethylenediamine (the mass percentage of bio-based pentamethylenediamine is 24%, its addition is the sum of bio-based pentamethylenediamine and adipic acid) 0.08%) 5g, flame retardant TL-C1 480g (the addition is 8% of the sum of bio-based pentamethylenediamine and adipic acid) and modified melamine cyanurate 180g (the addition is bio-based Pentamethylenediamine and adipic acid (3% of the sum of the mass added) were added together into the reactor, and the temperature was kept at 235° C. and the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Cold crystallization temperature | aaaaa | aaaaa |

| Sticky number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com