Epoxy coating as well as preparation method and application method thereof

A technology of epoxy coatings and coating methods, which is applied in the direction of epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve the problems of poor adaptability, cumbersome paint film maintenance and construction procedures, etc., and achieve construction efficiency improvement, good anti-corrosion ability, The effect of high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The epoxy coating of the present embodiment is made of iron red epoxy ester primer and Y 2 o 3 Composition, Y 2 o 3 The quality of iron red epoxy ester primer is 0.05% of the quality of iron red epoxy ester primer; the mass percentage of iron red epoxy ester primer consists of: iron red 22%, zinc yellow 12%, talcum powder 8.00%, ZnO7.00%, 10% Pb lead naphthenate 0.70%, 3% Co cobalt naphthenate 0.60%, 3% Mn manganese naphthenate 0.90%, 7:3 xylene / butanol 5%, the balance is 50% solid epoxy ester resin . Among them, 10% Pb lead naphthenate is a lead naphthenate solution with a mass concentration of 10%, and 3% Co cobalt naphthenate and 3% Mn manganese naphthenate have similar meanings.

[0028] The preparation method of the epoxy paint of the present embodiment comprises: Y 2 o 3 The powder is ground to a particle size of no more than 15 μm, then mixed evenly with the one-component iron red epoxy primer, and left to stand for 20-30 minutes to obtain the product.

[...

Embodiment 2~5

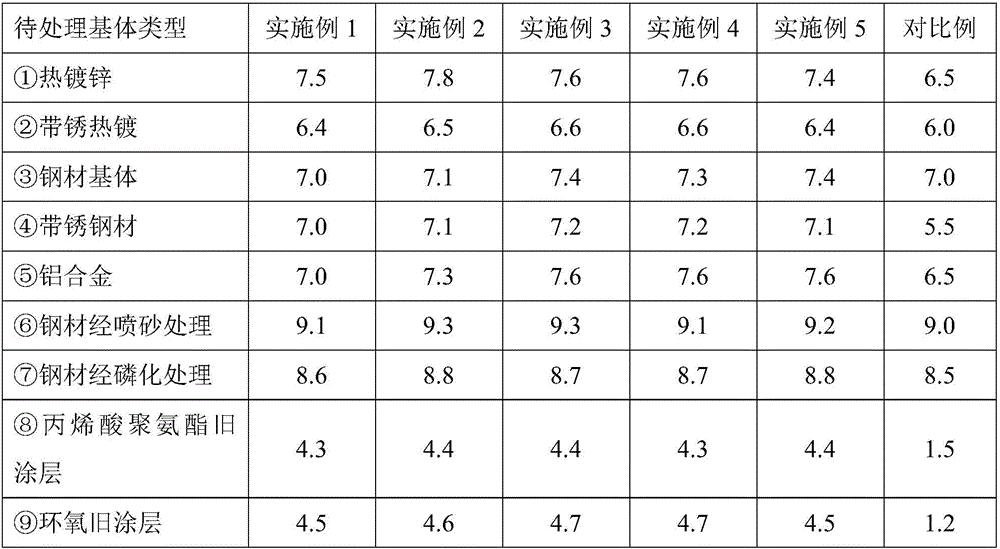

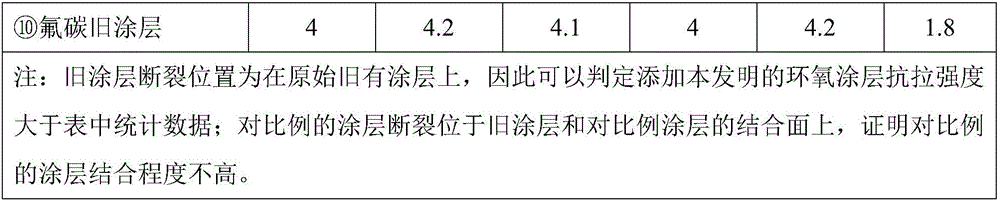

[0042] The epoxy coating of embodiment 2~5, by iron red epoxy ester primer and Y 2 o 3 Composition, Y 2 o 3 The quality of iron red epoxy ester primer is 0.1%, 0.15%, 0.2%, 0.25% respectively.

[0043] The preparation method of the epoxy coating of embodiment 2~5 is the same as the preparation method of the epoxy coating of embodiment 1.

[0044] The coating method of the epoxy coating of embodiment 2~5, the thickness of primer paint layer is respectively 40 μ m, 45 μ m, 50 μ m, 55 μ m, and the substrate to be treated and corresponding pretreatment of each embodiment are the same as embodiment 1; Back spray topcoat, the thickness of topcoat is identical with primer, and the construction parameters of primer, topcoat are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com