Preparation method of nano silver-loaded fluorinated graphene composite

A technology of fluorinated graphene and composite materials, applied in the direction of nanotechnology, metal material coating technology, gaseous chemical plating, etc., can solve the problem of the reduction of the effective specific surface area of the catalytic activity of composite materials, and the difficulty of uniform and sufficient distribution of nano-silver graphite To achieve the effect of maintaining adsorption stability and permanence, uniform doping, and increasing loading rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the purpose, features and advantages of the present invention clearer, the specific implementation of the present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments. In the following description, many specific details are set forth for the convenience of The invention is fully understood, but it can be practiced in many other ways than that described. Accordingly, the present invention is not limited to the specific implementations disclosed below.

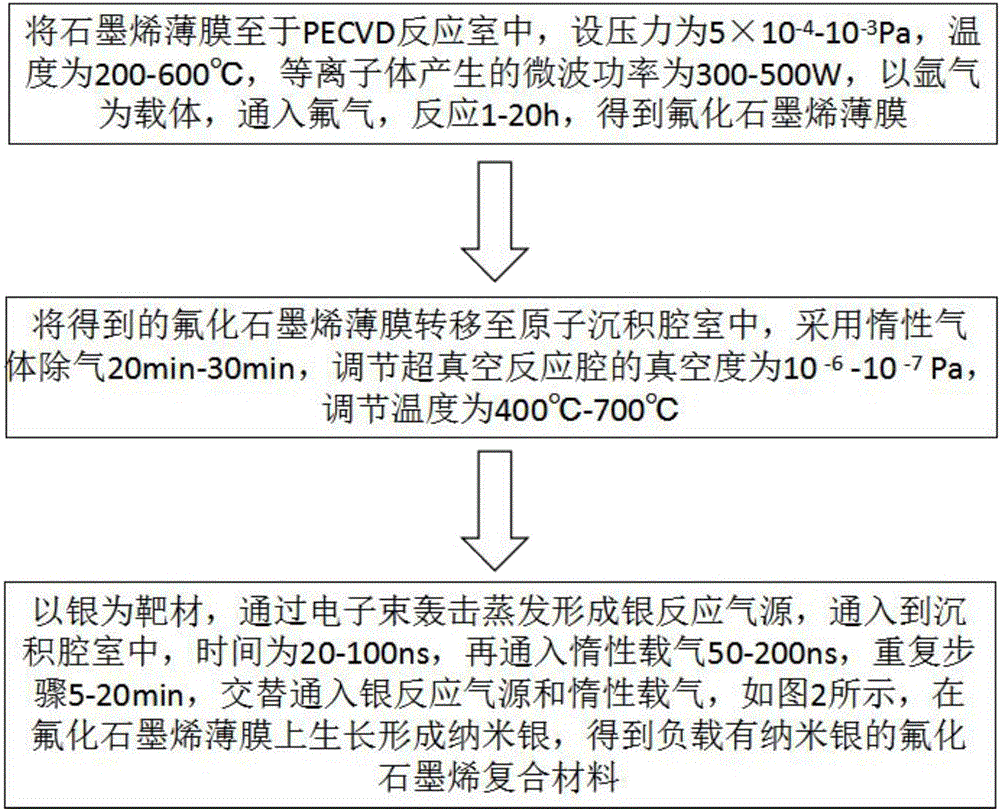

[0022] A kind of preparation method of the fluorinated graphene composite material loaded with nano-silver, such as figure 1 shown, including the following steps:

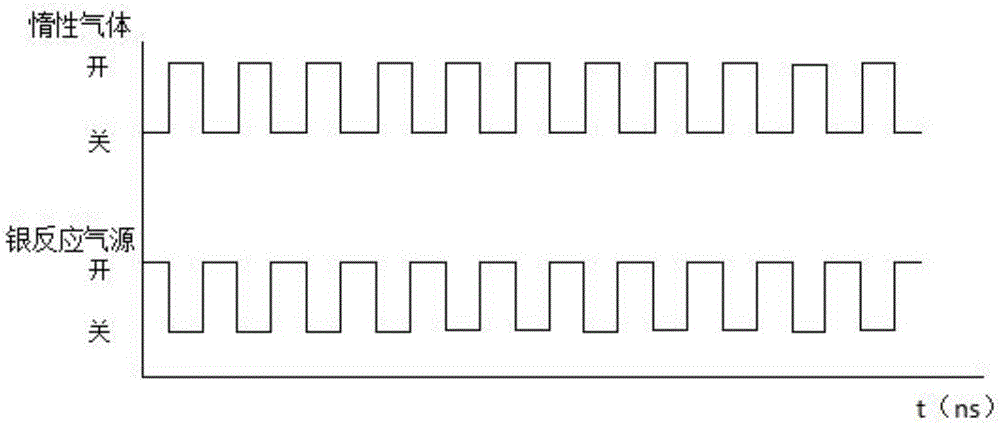

[0023] 1) Put the graphene film in the PECVD reaction chamber, set the pressure at 5×10-4-10-3Pa, the temperature at 200-600°C, and the microwave power generated by the plasma at 300-500W, with argon as the carrier, pass Enter fluorine gas, react for 1-20h, and obtain fluorinated grap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com