Packing paper with effect of halo in many colors and production technology thereof

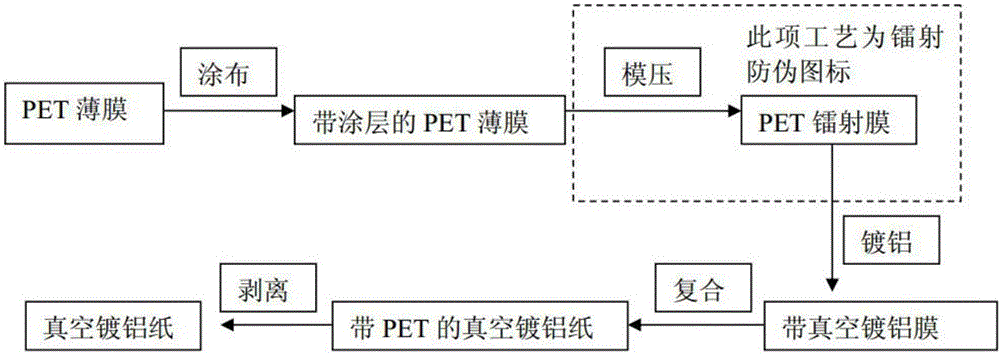

A production process and technology of wrapping paper, applied in the directions of wrapping paper, wrapping paper, packaging, etc., can solve the problems of unstable printing applicability, insufficient three-dimensional effect, poor metal texture, etc. Strong alkaline hydrolysis ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

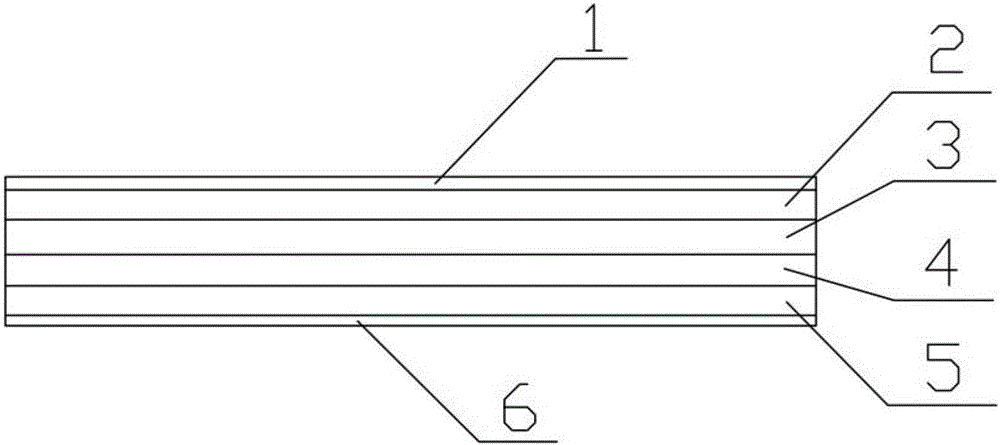

Method used

Image

Examples

Embodiment 1

[0057] The preparation of the wrapping paper with halo effect of embodiment 1 comprises the following steps:

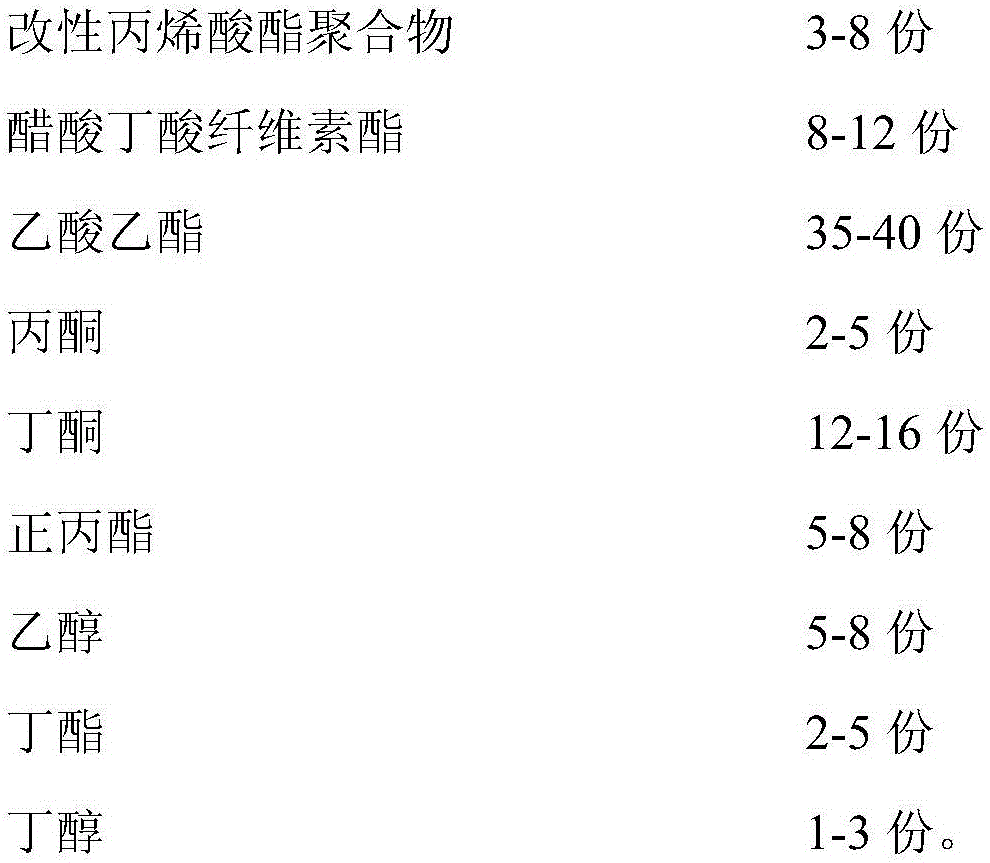

[0058] (1) Preparation of transfer coating: put 8 parts of modified acrylate polymer, 8 parts of cellulose acetate butyrate, 5 parts of acetone, and 13 parts of methyl ethyl ketone into the reaction kettle in turn, stir evenly at 1000r / min, and heat up to 35 ℃; then add 38 parts of ethyl acetate, 8 parts of n-propyl ester, 6 parts of ethanol, 3 parts of butyl ester and 3 parts of butanol in sequence, keep the temperature at 35 ℃, stir for 20 minutes, then raise the temperature to 45 ℃, stir 1.5h, cooling and discharge to obtain transfer coating;

[0059] (2) Coating: the wet coating amount is 9-10g / m 2 The reticulated roller, with one-sided one-time coating method, coats the transfer coating prepared in step (1) on the PET film, centering the edge when coating, controlling the width of the edge on one side to be less than 0.5mm, and the dry coating amount is 1.55 g / ...

Embodiment 2

[0064] The preparation of the wrapping paper with halo effect of embodiment 2 comprises the following steps:

[0065] (1) Preparation of transfer coating: Put 6 parts of modified acrylate polymer, 10 parts of cellulose acetate butyrate, 3.5 parts of acetone, and 14 parts of methyl ethyl ketone into the reaction kettle in turn, stir evenly at 1200r / min, and heat up to 35 ℃; then add 37 parts of ethyl acetate, 6 parts of n-propyl ester, 7 parts of ethanol, 3 parts of butyl ester and 3 parts of butanol in sequence, keep the temperature at 35 ℃, stir for 20 minutes, then raise the temperature to 40 ℃, stir 2h, cooling and discharging to obtain transfer coating;

[0066] (2) Coating: the wet coating amount is 9-10g / m 2 The reticulated roller, with one-sided one-time coating method, coats the transfer coating prepared in step (1) on the PET film, centering the edge when coating, controlling the width of the edge on one side to be less than 0.5mm, and the dry coating amount is 1.45 ...

Embodiment 3

[0071] The preparation of the wrapping paper with halo effect of embodiment 3 comprises the following steps:

[0072] (1) Preparation of transfer coating: Put 6 parts of modified acrylate polymer, 10 parts of cellulose acetate butyrate, 3.5 parts of acetone, and 14 parts of methyl ethyl ketone into the reaction kettle in turn, stir evenly at 1200r / min, and heat up to 35 ℃; then add 37 parts of ethyl acetate, 6 parts of n-propyl ester, 7 parts of ethanol, 3 parts of butyl ester and 3 parts of butanol in sequence, keep the temperature at 35 ℃, stir for 20 minutes, then raise the temperature to 40 ℃, stir 2h, cooling and discharging to obtain the transfer coating; wherein, the cellulose acetate butyrate is modified by barium oxide before use, and the amount of barium oxide is 0.3wt% of the cellulose acetate butyrate;

[0073] (2) Coating: the wet coating amount is 9-10g / m 2 The reticulated roller, with one-sided one-time coating, coats the transfer coating prepared in step (1) o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com