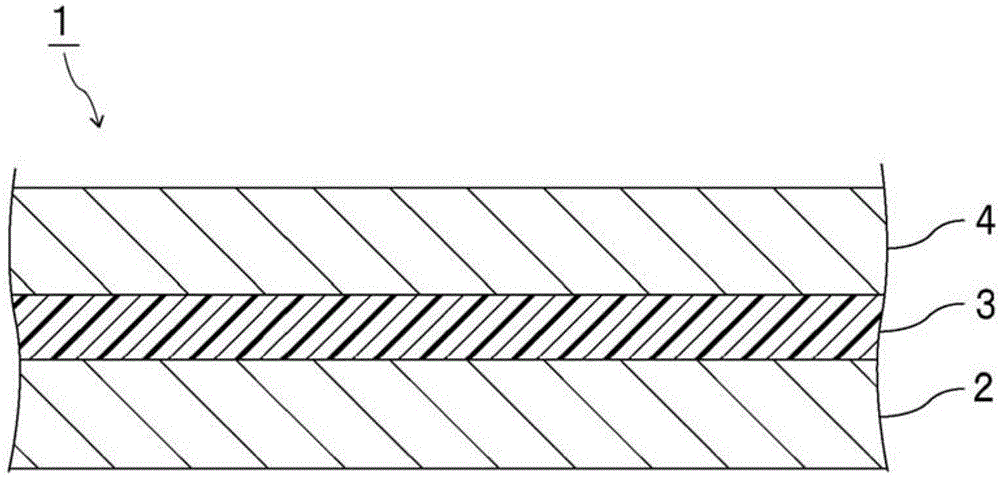

Inkjet photo- and heat-curable adhesive, semiconductor device manufacturing method, and electronic part

A heat-curable and light-curable technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, adhesive heating bonding methods, etc., can solve the problem of lower reliability, lower thickness precision of the adhesive layer, Problems such as high elastic modulus, to achieve the effect of not being easy to void and improving thickness accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

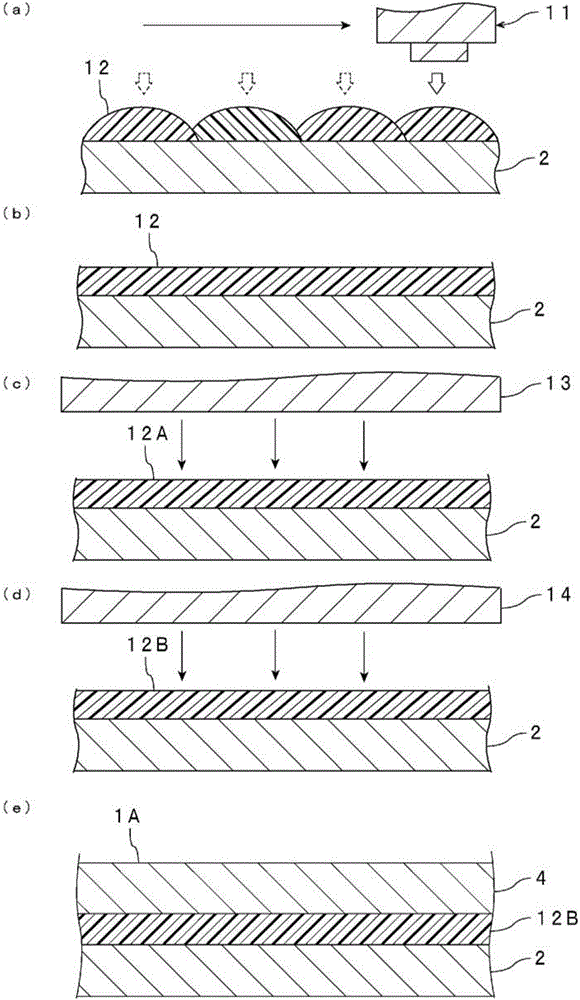

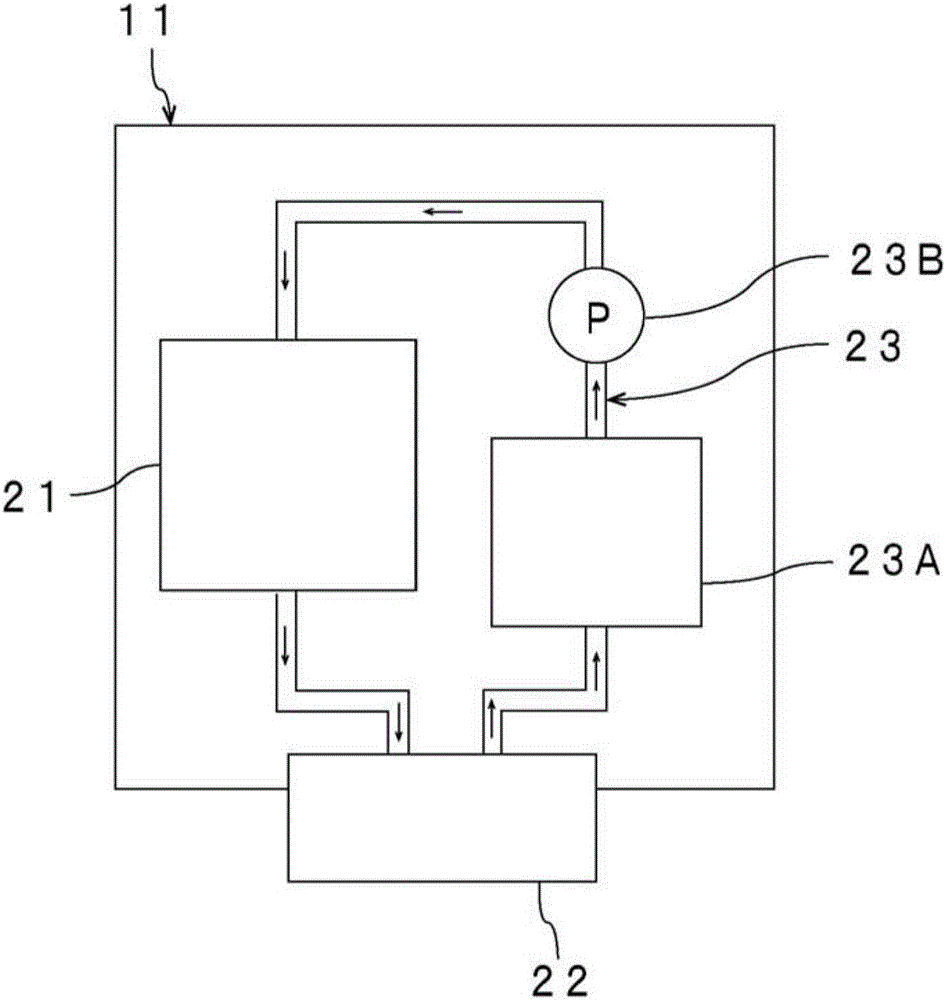

Method used

Image

Examples

Embodiment 1

[0227] (Preparation of Adhesive A)

[0228] As a photocurable compound, 2 parts by weight of tricyclodecane dimethanol diacrylate ("IRR-214K" manufactured by Daicel-Allnex Co., Ltd.), 11 parts by weight of lauryl acrylate ("L-A" manufactured by Kyoeisha Chemical Co., Ltd.) Parts by weight, 41 parts by weight of 4-hydroxybutyl acrylate glycidyl ether ("4HBAGE" manufactured by Nippon Chemicals Co., Ltd.) as a light and thermosetting compound, bisphenol A type epoxy resin (new "YD-127" manufactured by Nippon Steel Sumikin Chemical Co., Ltd.) 20 parts by weight, 20 parts by weight of an acid anhydride having a terpene skeleton ("YH306" manufactured by Mitsubishi Chemical Corporation) as a thermosetting agent, DBU as a curing accelerator - 1 part by weight of caprylic acid salt ("UCAT SA-102" manufactured by SAN-APRO Co., Ltd.), and 2-benzyl-2-dimethylamino-1-(4-morpholino) as a photopolymerization initiator 5 parts by weight of phenyl)-butanone-1 ("IRGACURE 369" manufactured by B...

Embodiment 2~16 and comparative example 1~3

[0230] (Preparation of Adhesives B to P)

[0231] Adhesives B to S were prepared in the same manner as the above-mentioned adhesive agent A except that the components shown in the following Table 1 were blended in the compounding amounts shown in the following Tables 2 and 3.

[0232] (evaluate)

[0233] (Viscosity of the adhesive at 25°C and 10rpm)

[0234] The viscosity of the adhesive at 25° C. and 10 rpm was measured using an E-type viscometer (“TVE22L” manufactured by Toki Sangyo Co., Ltd.) in accordance with JIS K2283. The viscosity was evaluated according to the following criteria.

[0235] [Criteria for judging viscosity]

[0236] A: The viscosity exceeds 1600mPa·s

[0237] B: The viscosity exceeds 1000 mPa·s and is 1600 mPa·s or less

[0238] C: The viscosity exceeds 500 mPa·s and is 1000 mPa·s or less

[0239]D: The viscosity is 160 mPa·s or more and 500 mPa·s or less

[0240] E: The viscosity is more than 5mPa·s and less than 160mPa·s

[0241] F: Viscosity l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com