Pressure-sensitive adhesive composition and acrylic pressure-sensitive adhesive composition

一种压敏胶粘剂、组合物的技术,应用在压敏胶粘剂组合物和丙烯酸类压敏胶粘剂组合物领域,能够解决压敏胶粘剂变硬、粘性降低、粘合剂粘合性能不充分等问题,达到耐热性和耐光性优良、粘性良好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

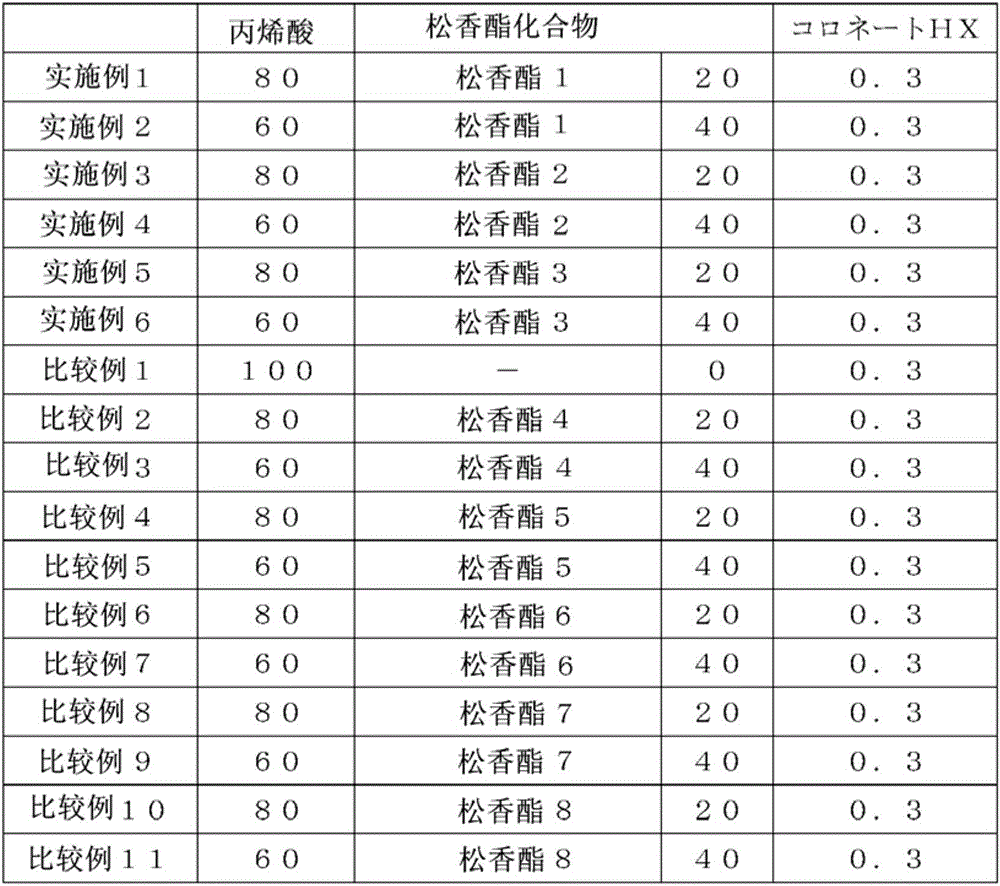

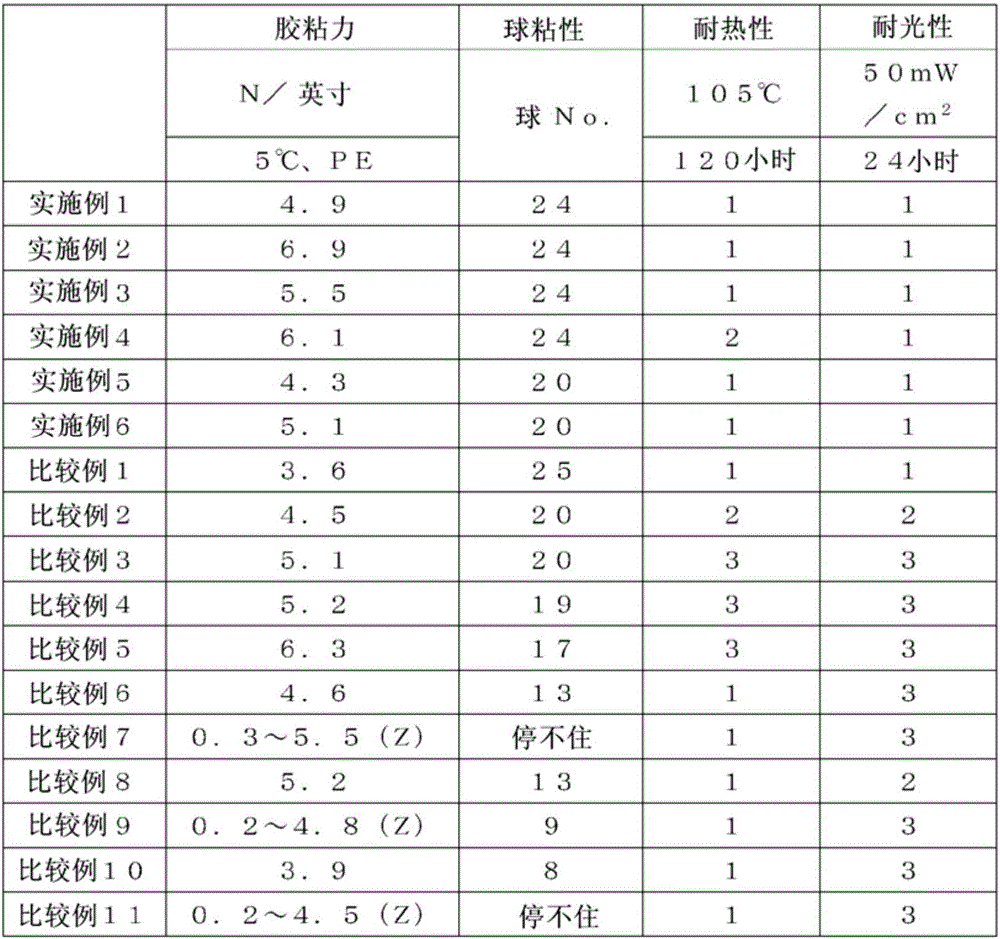

Examples

manufacture example 1

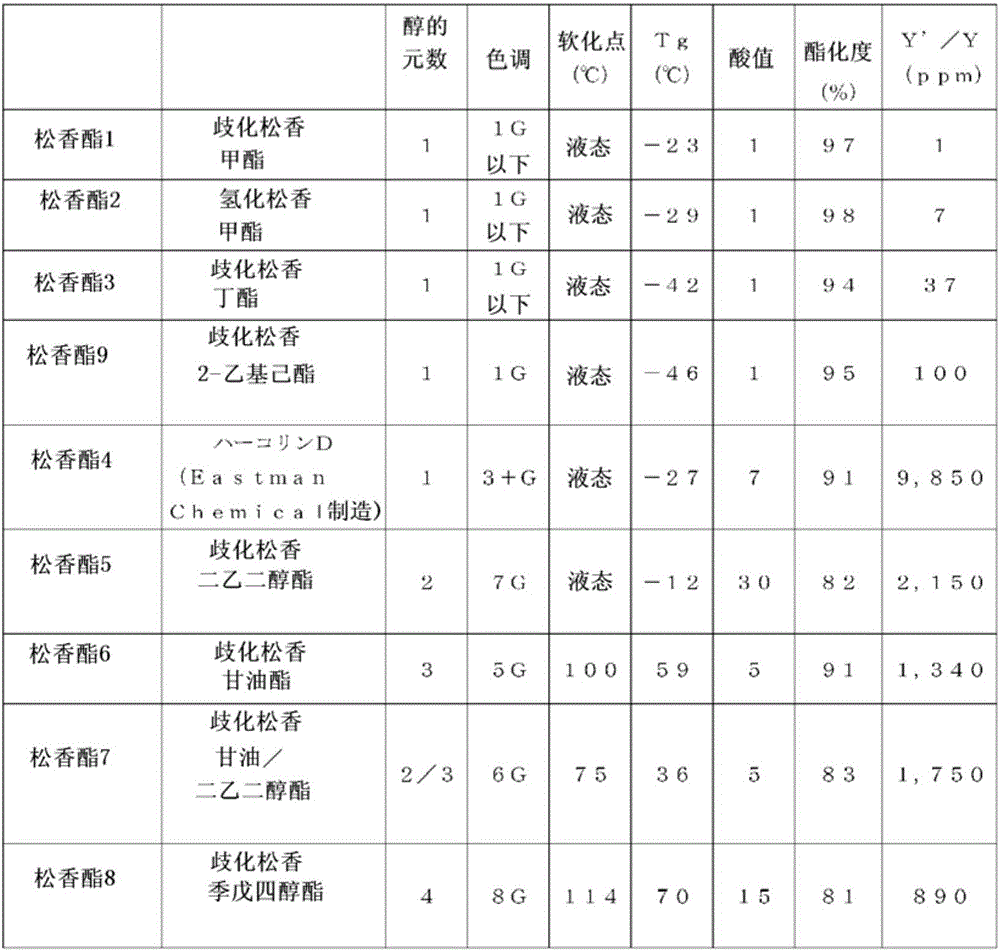

[0077] Production example 1 (production of rosin ester 1)

[0078] 100 g of Chinese disproportionated rosin (manufactured by Arakawa Chemical Co., Ltd., Wuzhou, Guangxi) and 300 g of methanol were put into a 1 L autoclave, and after removing oxygen in the system, the temperature was raised to 290°C. The inner pressure of the autoclave reached 14 MPa at the maximum. The contents were allowed to react for 2 hours while blowing air every 20 minutes. After concentrating the obtained reaction solution with a rotary evaporator, 5 g of calcium hydroxide was added and simple distillation was performed. Under conditions of a liquid temperature of 150 to 270° C. and a pressure of 0.4 kPa, 6 g of an initial fraction was removed to obtain 68 g of rosin ester 1 as a main fraction.

manufacture example 2

[0079] Production example 2 (production of rosin ester 2)

[0080] 65 g of rosin ester 2 were obtained in the same manner as in Production Example 1 except that the Chinese disproportionated rosin in Production Example 1 was changed to Chinese Hydrogenated Rosin (manufactured by Guangxi Wuzhou Richeng Forestry Chemical Co., Ltd.).

manufacture example 3

[0081] Production example 3 (production of rosin ester 3)

[0082] 100 g of Chinese disproportionated rosin (manufactured by Arakawa Chemical, Wuzhou, Guangxi) and 300 g of n-butanol were charged into a 1 L autoclave, and after removing oxygen in the system, the temperature was raised to 290°C. The internal pressure of the autoclave reached 10 MPa at the maximum. The contents were allowed to react for 2 hours while blowing air every 20 minutes. After concentrating the obtained reaction solution with a rotary evaporator, 5 g of calcium hydroxide was added and simple distillation was performed. Under conditions of a liquid temperature of 150 to 270° C. and a pressure of 0.4 kPa, 5 g of the initial fraction was removed to obtain 71 g of rosin ester 3 as the main fraction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com