A single-phase or multi-phase reaction device that effectively improves mixing intensity and mass transfer rate

A technology of mixing intensity and multiphase reaction, which is applied in the field of chemical equipment, can solve the problems of low mixing intensity and mass transfer rate, large floor area, and bulky volume, and achieve the goals of reducing energy consumption, compact size, and enhancing mass transfer rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Material preparation: CuSO 4 ·5H 2 O and Fe 2 (SO 4 ) 3 Dissolved in deionized water to obtain a concentration of Cu 2+ =3g / l, Fe 3+ =1g / l aqueous solution. At the same time, use DZ988N copper extractant and 260# kerosene to obtain an organic phase with a volume fraction of about 15%, and the organic phase does not need to be saponified.

[0045] Before using the magnetic pH meter to detect the acidity of the solution, use acidic pH buffer (pH=4.0, pH=6.86) to calibrate it twice, and then use NaOH solution and H 2 SO 4 The solution adjusts the acidity of the solution to a pH of 2.

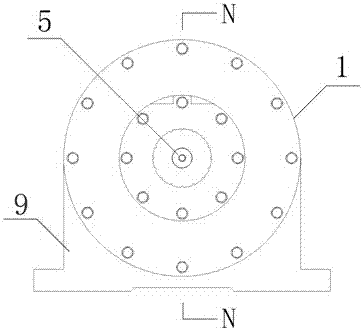

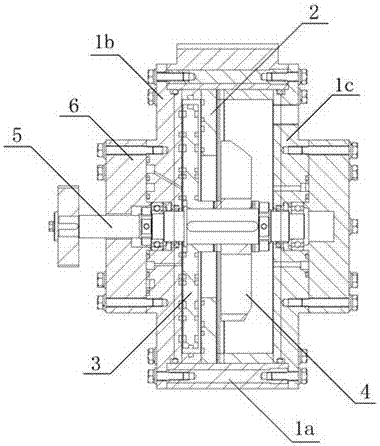

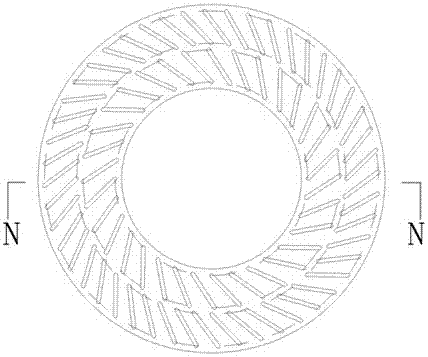

[0046] Parameter setting: the distance between the mass transfer disk 3 and the feed end cover 1b of the test device is 0.5mm, the distance between the mass transfer disk 3 and the isolation ring disk 2 is 0.5mm, and the motor drives the transmission shaft at a speed of 500r / min; the flow rate of the organic phase is 500ml / min, and the flow rate of the aqueous phase is 250ml / min.

...

Embodiment 2

[0050] Material preparation: CuSO 4 ·5H 2 O and Fe 2 (SO 4 ) 3 Dissolved in deionized water to obtain a concentration of Cu 2+ =0.6 g / l, Fe 3+ =2g / l aqueous solution. At the same time, use DZ988N copper extractant and 260# kerosene to obtain an organic phase with a volume fraction of about 15%, and the organic phase does not need to be saponified.

[0051] Before using the magnetic pH meter to detect the acidity of the solution, use acidic pH buffer (pH=4.0, pH=6.86) to calibrate it twice, and then use NaOH solution and H 2 SO 4 The solution adjusts the acidity of the solution to a pH of 2.

[0052] Parameter setting: the distance between the mass transfer disk 3 and the feed end cover 1b of the test device is 0.01mm, the distance between the mass transfer disk 3 and the isolation ring disk 2 is 0.01mm, and the motor drives the transmission shaft at a speed of 50r / min; the flow rate of the organic phase is 500ml / min, and the flow rate of the aqueous phase is 250ml / mi...

Embodiment 3

[0055] Material preparation: CuSO 4 ·5H 2 O and Fe 2 (SO 4 ) 3 Dissolved in deionized water to obtain a concentration of Cu 2+= 0.3g / l, Fe 3+ =5g / l aqueous solution. At the same time, use DZ988N copper extractant and 260# kerosene to obtain an organic phase with a volume fraction of about 15%, and the organic phase does not need to be saponified.

[0056] Before using the magnetic pH meter to detect the acidity of the solution, use acidic pH buffer (pH=4.0, pH=6.86) to calibrate it twice, and then use NaOH solution and H 2 SO 4 The solution adjusts the acidity of the solution to a pH of 2.

[0057] Parameter setting: the distance between the mass transfer disk 3 and the feed end cover 1b of the test device is 10mm, the distance between the mass transfer disk 3 and the isolation ring disk 2 is 10mm, and the motor drives the transmission shaft at a speed of 5000r / min; The organic phase flow rate is 500ml / min, and the aqueous phase flow rate is 250ml / min.

[0058] Test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com