Activated carbon-based formaldehyde removal material and preparation method thereof

A technology of activated carbon and formaldehyde, applied in separation methods, chemical instruments and methods, other chemical processes, etc., can solve the problems of high application conditions, low aldehyde removal efficiency and high absorption rate, and achieve low application conditions and aldehyde removal efficiency. High and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

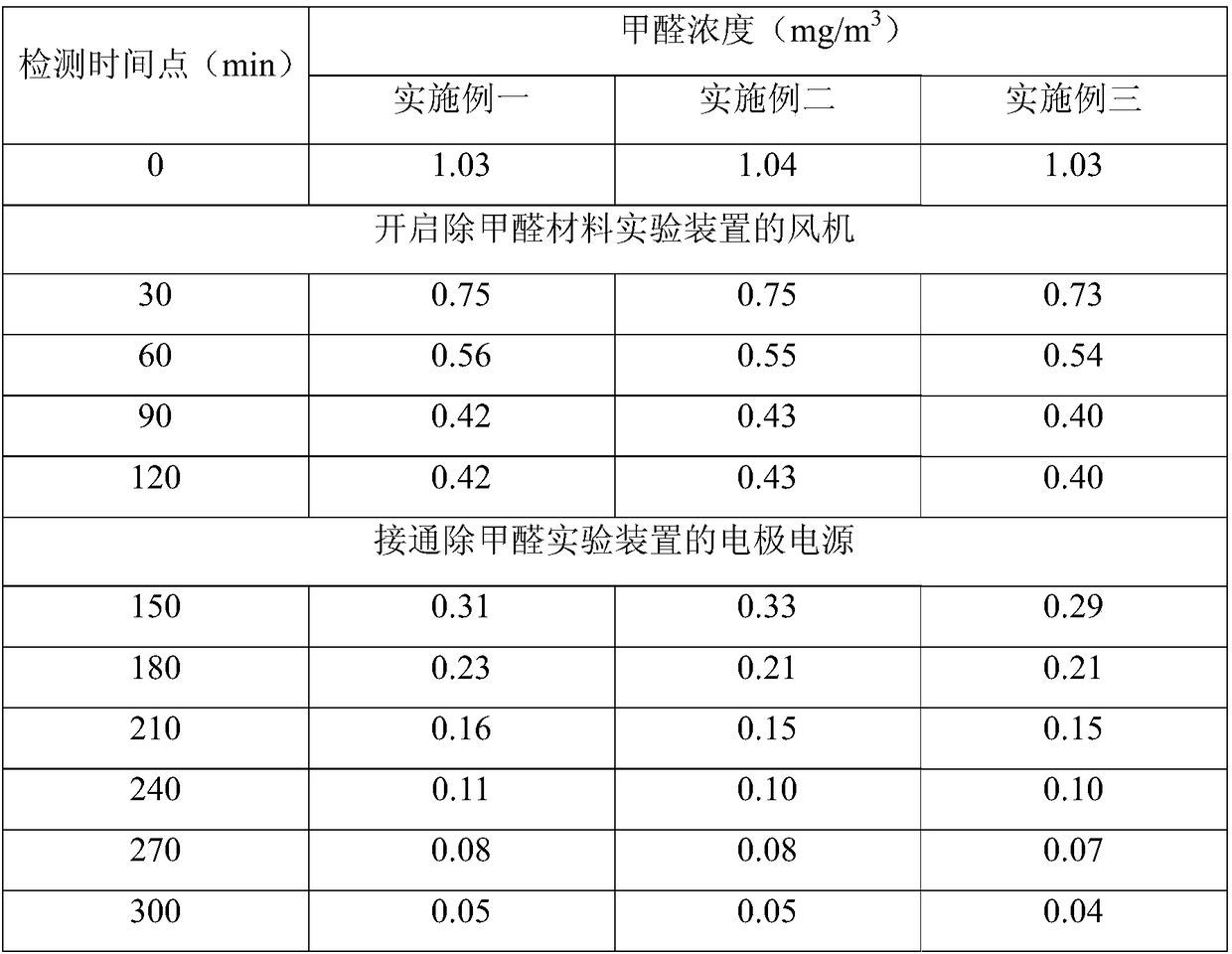

Embodiment 1

[0018] 1. The configuration of titanium dioxide dispersion liquid: take nano-scale titanium dioxide at a concentration of 2% and place it in deionized water, stir it magnetically for 30 minutes (rotation number is 1000-1800r / min, temperature is 25-37°C), stir and dissolve, pour ultrasonic wave Disperse in a disperser for 40 minutes to prepare a titanium dioxide dispersion;

[0019] 2. Configuration of potassium permanganate solution: Dissolve potassium permanganate in deionized water at a concentration of 8%, stir magnetically for 30 minutes (rotation number is 1000-1800r / min, temperature is 25-37°C), and high Potassium manganate solution;

[0020] 3. Activated carbon loaded with potassium permanganate treatment: Weigh the activated carbon according to the mass ratio of 60% of the total mass of the finished material, crush it and pass through a 50-100 mesh sieve, pour it into 1 / 2 of the potassium permanganate solution, and stir it magnetically for 3 hours (The number of revol...

Embodiment 2

[0025] 1. The configuration of titanium dioxide dispersion liquid: take nano-scale titanium dioxide at a concentration of 5% and place it in deionized water, stir it magnetically for 40 minutes (rotation number is 1000-1800r / min, temperature is 25-37°C), stir and dissolve, pour ultrasonic wave Disperse in a disperser for 50 minutes to prepare a titanium dioxide dispersion;

[0026] 2. Configuration of potassium permanganate solution: Dissolve potassium permanganate in deionized water at a concentration of 10%, stir magnetically for 30 minutes (rotation number is 1000-1800r / min, temperature is 25-37°C), and high Potassium manganate solution;

[0027] 3. Activated carbon loaded with potassium permanganate treatment: Weigh the activated carbon according to the mass ratio of 55% of the total mass of the finished material, crush it and pass through a 50-100 mesh sieve, pour it into 1 / 2 of the potassium permanganate solution, and stir it magnetically for 4 hours (The number of revo...

Embodiment 3

[0032] 1. The configuration of titanium dioxide dispersion liquid: take nano-scale titanium dioxide at a concentration of 3% and place it in deionized water, stir it magnetically for 30 minutes (rotation number is 1000-1800r / min, temperature is 25-37°C), stir and dissolve, pour ultrasonic Disperse in a disperser for 30 minutes to prepare a titanium dioxide dispersion;

[0033] 2. Configuration of potassium permanganate solution: Dissolve potassium permanganate in deionized water at a concentration of 4%, and stir magnetically for 40 minutes (rotation number is 1000-1800r / min, temperature is 25-37°C), and high Potassium manganate solution;

[0034] 3. Activated carbon loaded with potassium permanganate treatment: Weigh the activated carbon according to the mass ratio of 65% of the total mass of the finished material, crush it and pass through a 50-100 mesh sieve, pour it into 1 / 2 of the potassium permanganate solution, and stir it magnetically for 5 hours (The number of revolu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com