Method for preparing copper substrate with two wetting characteristics of hydrophility and hydrophobicity

A technology of wetting characteristics and copper substrate, which is applied to the device of coating liquid on the surface, vacuum evaporation plating, coating, etc., can solve the problem of condensate droplet adhesion, improve heat exchange efficiency, and facilitate mass production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

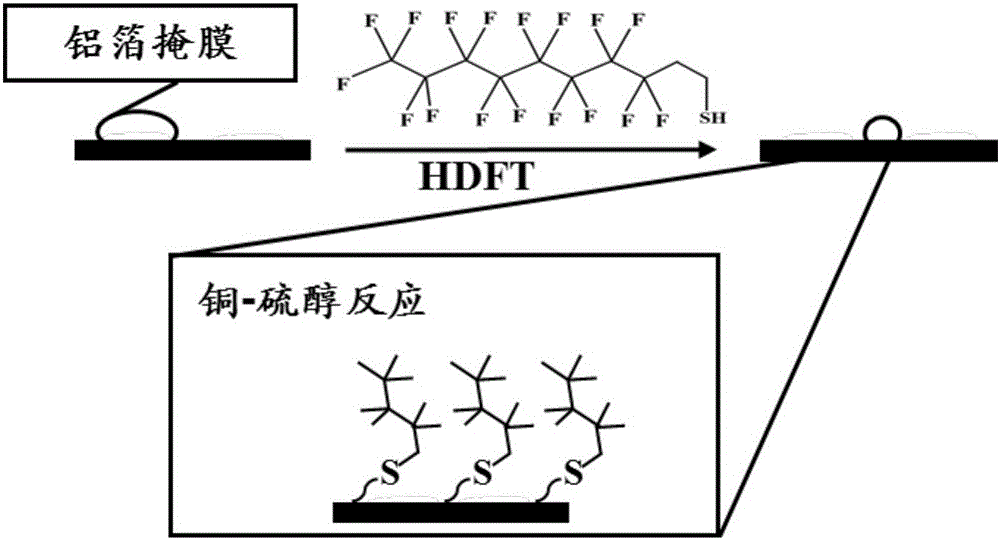

[0032] Embodiment 1 includes electron beam evaporation coating step, plasma treatment step, preparation of molecular self-assembled film (SAM) step and experimental verification step:

[0033] A, electron beam evaporation coating step, including the following sub-steps:

[0034] Sub-step A1: immerse the smooth copper plate 30mm×30mm×1mm polished by sandpaper into a beaker filled with 50mL of dichloromethane (DCM, 99%) solution, and put the beaker into an ultrasonic cleaner for 10 minutes to take it out;

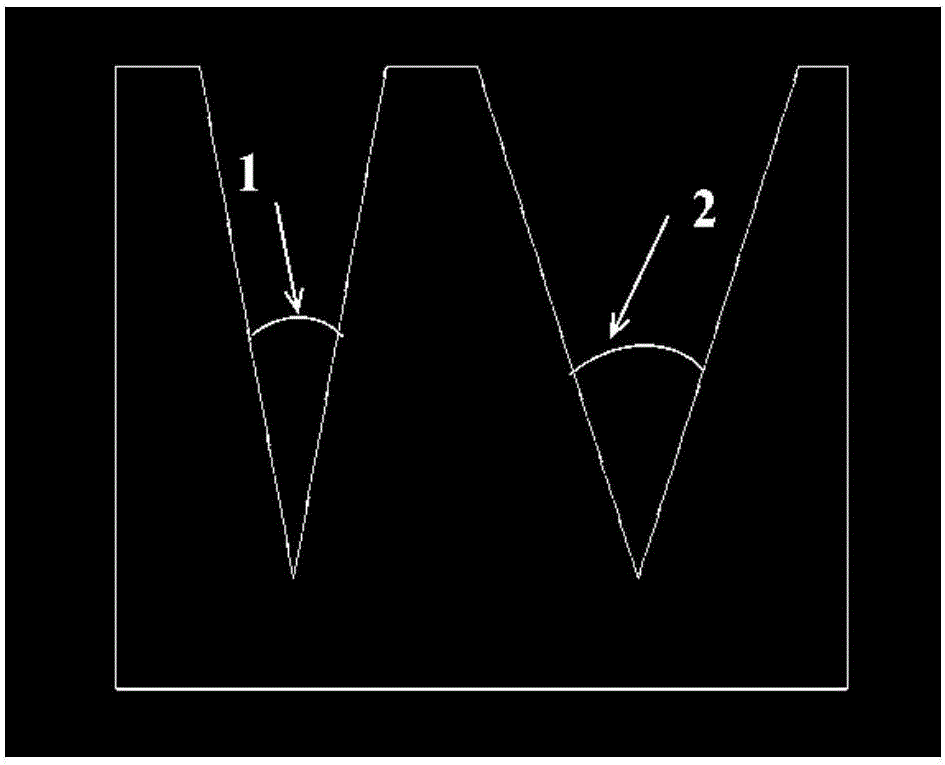

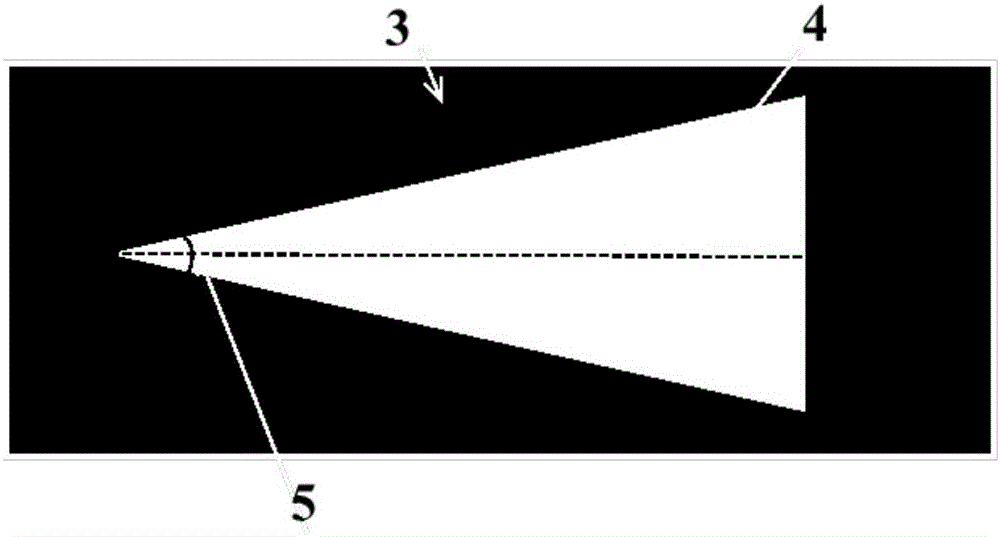

[0035] Sub-step A2: Take the aluminum foil and cut out the desired pattern (wedge-shaped areas with top angles of 20° and 35° respectively), such as figure 1 , the cut aluminum foil is used as a mask to cover the copper plate;

[0036] Sub-step A3: Fix the back of the masked copper plate on the sample stage with high-temperature double-sided adhesive, and then put it into an electron beam evaporation coating machine for aluminum plating, and the coating thickness is 50nm;

...

Embodiment 2

[0048] Embodiment 2, including electron beam evaporation coating step, plasma treatment step, preparation molecular self-assembled thin film (SAM) step and experimental verification step:

[0049] A, electron beam evaporation coating step, including the following sub-steps:

[0050] Sub-step A1: immerse the smooth copper plate 30mm×30mm×1mm polished by sandpaper into a beaker filled with 50mL of dichloromethane (DCM, 99%) solution, and put the beaker into an ultrasonic cleaner for 20 minutes to take it out;

[0051] Sub-step A2: If figure 1 , take the aluminum foil paper, cut out the required pattern (wedge-shaped area with top angles of 20° and 35° respectively), and use the cut aluminum foil paper as a mask to cover the copper plate;

[0052]Sub-step A3: Fix the back of the masked copper plate on the sample stage with high-temperature double-sided adhesive, and then put it into an electron beam evaporation coating machine for aluminum plating, and the coating thickness is 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com