Toughened and modified small scale bulk powder polypropylene and preparation method thereof

A small bulk polypropylene, toughening modification technology, applied in the field of polymer materials, can solve the problems of limited toughening effect, reduction of blend modulus, strength and heat distortion temperature, without reducing tensile strength and rigidity , to achieve good toughening effect, reduce cost and research and development costs, and increase added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

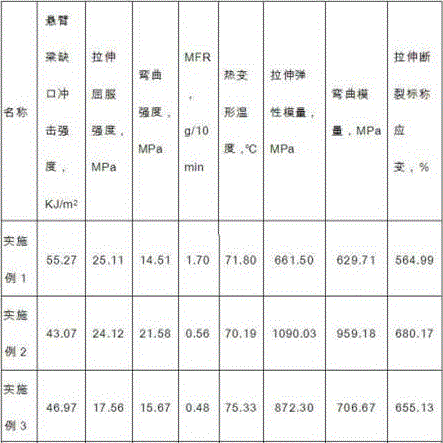

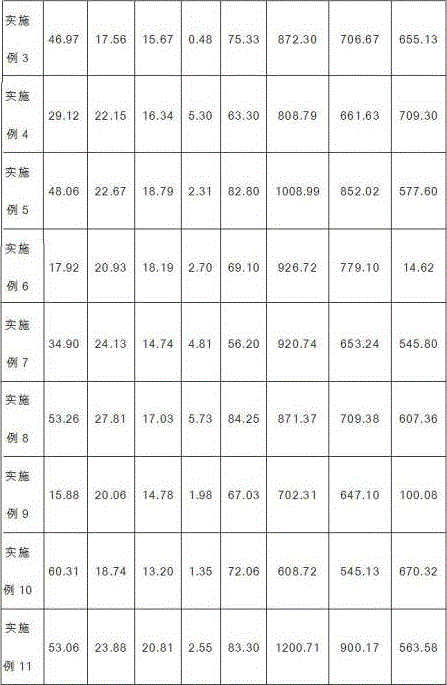

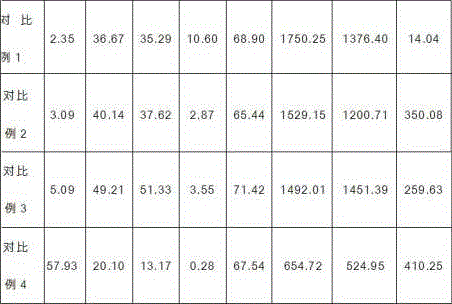

Examples

Embodiment 1

[0038] Carry out this test by following raw material mass parts:

[0039] 1) Small body powder polypropylene (PPH075) 50 parts

[0040] Copolymerized polypropylene (PPR1003) 15 parts

[0041] 2) Toughening agent (POE8150) 25 parts

[0042] 3) Filler (white carbon black treated with KH550) 5 parts

[0043] 4) Antioxidant (1010) 1.0 parts

[0044] Antioxidant (168) 0.1 parts

[0045] 5) Lubricant (polyethylene wax) 2.0 parts

[0046] 6) Dispersant (calcium stearate) 1.0 parts

[0047] Include the following steps:

[0048] 1) Dissolve white carbon black in water and methanol (1:1) solution (mass concentration is 10%), ultrasonically oscillate for 0.5h, after stopping the oscillation, add KH550 which accounts for 3% of the mass fraction of white carbon black, continue Ultrasonic oscillation for 1 hour, then place the solution in a water bath at 70°C and heat it to reflux for 8 hours, centrifuge after stopping the reflux, and dry it in an oven at 100°C for later use;

[004...

Embodiment 2

[0054] Carry out this test by following raw material mass parts:

[0055] 1) Polypropylene (PPH075) 80 parts

[0056] Polypropylene (PPR1003) 5 parts

[0057] 2) Toughening agent (POE8150) 5 parts

[0058] 3) Filler (calcium carbonate treated with NDZ101) 6 parts

[0059] 4) Antioxidant (1010) 1.0 parts

[0060] Antioxidant (168) 0.1 parts

[0061] 5) Lubricant (polyethylene wax) 2.0 parts

[0062] 6) Dispersant (calcium stearate) 1.0 parts

[0063] Include the following steps:

[0064] 1) Add light calcium carbonate (mass concentration: 20 parts) to the toluene solvent, ultrasonically oscillate for 0.5h, stop the oscillation, add NDZ101 which accounts for 2% of the mass fraction of calcium carbonate, continue ultrasonically oscillating for 1h, and then the solution Place in a water bath at 70°C and heat to reflux for 8 hours, centrifuge after stopping the reflux, and dry in an oven at 100°C for later use;

[0065] 2) Dry the small bulk polypropylene, antioxidant, disp...

Embodiment 3

[0070] Carry out this test by following raw material mass parts:

[0071] 1) Polypropylene (PPH075) 50 parts

[0072] Polypropylene (PPR1003) 6 parts

[0073] 2) Toughening agent (POE8150) 10 parts

[0074] 3) Filler (white carbon black treated with KH550) 30 parts

[0075] 4) Antioxidant (1010) 1.0 parts

[0076] Antioxidant (168) 0.1 parts

[0077] 5) Lubricant (polyethylene wax) 2.0 parts

[0078] 6) Dispersant (calcium stearate) 1.0 parts

[0079] Experimental procedure and test method are the same as in Example 1, and the test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com