Track material for stadium

A technology for sports fields and runways, which is applied in the field of runway materials, can solve the problems of incompletely improving the rebound rate, tensile strength and elongation at break of plastic runways, and restrict the performance of plastic runways, so as to achieve good rebound rate and good performance. The effect of corrosion resistance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

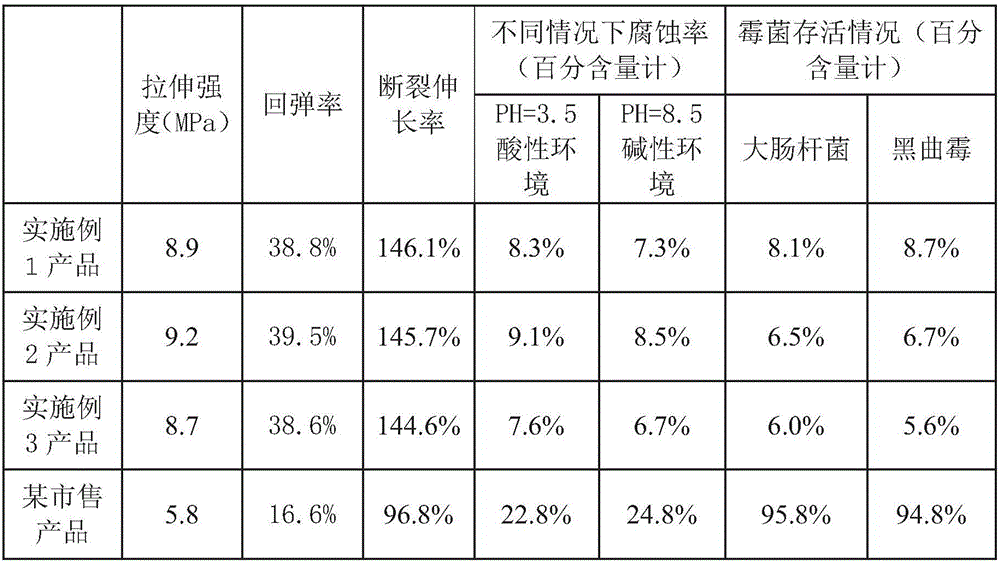

Examples

Embodiment 1

[0019] The running track material for the sports field in the present embodiment is composed of the following components in parts by mass: 16 parts of methyl silicone resin, 18 parts of fluff powder, 14 parts of strontium chromate, 12 parts of nitrile rubber powder, trimellitic acid 18 parts of trioctyl ester, 14 parts of barium sulfate powder, 12 parts of olivine powder, 18 parts of quartz powder, 14 parts of trilead tetraoxide powder, 12 parts of polytetrahydrofuran ether glycol, 18 parts of isothiazolinone, 14 parts of titanium dioxide , 14 parts of trimethoxysilane, 12 parts of triethylene glycol diisocaprylate, 18 parts of dilauryl thiodipropionate, 14 parts of tert-butyl peroxybenzoate, 12 parts of methyl vinyl silicone rubber, 18 parts of oxygenated soybean oil, 14 parts of styrene-butadiene rubber, 12 parts of molybdenum disulfide, 18 parts of aluminum stearate, 14 parts of cellulose acetate, 12 parts of polyester acrylic resin, 18 parts of ethoxyquinoline, paraben 14 ...

Embodiment 2

[0027] The running track material for the sports field in the present embodiment is composed of the following components in parts by mass: 18 parts of methyl silicone resin, 20 parts of fluff powder, 16 parts of strontium chromate, 14 parts of nitrile rubber powder, trimellitic acid 20 parts of trioctyl ester, 16 parts of barium sulfate powder, 14 parts of olivine powder, 20 parts of quartz powder, 16 parts of trilead tetraoxide powder, 14 parts of polytetrahydrofuran ether glycol, 20 parts of isothiazolinone, 16 parts of titanium dioxide , 16 parts of trimethoxysilane, 14 parts of triethylene glycol diisocaprylate, 20 parts of dilauryl thiodipropionate, 16 parts of tert-butyl peroxybenzoate, 14 parts of methyl vinyl silicone rubber, 20 parts of oxygenated soybean oil, 16 parts of styrene-butadiene rubber, 14 parts of molybdenum disulfide, 20 parts of aluminum stearate, 16 parts of cellulose acetate, 14 parts of polyester acrylic resin, 20 parts of ethoxyquinoline, paraben 16 ...

Embodiment 3

[0035] The sports track material used in the present embodiment is composed of the following components in parts by mass: 20 parts of methyl silicone resin, 22 parts of fluff powder, 18 parts of strontium chromate, 16 parts of nitrile rubber powder, trimellitic acid 22 parts of trioctyl ester, 18 parts of barium sulfate powder, 16 parts of olivine powder, 22 parts of quartz powder, 18 parts of trilead tetraoxide powder, 16 parts of polytetrahydrofuran ether glycol, 22 parts of isothiazolinone, 18 parts of titanium dioxide , 18 parts of trimethoxysilane, 16 parts of triethylene glycol diisocaprylate, 22 parts of dilauryl thiodipropionate, 18 parts of tert-butyl peroxybenzoate, 16 parts of methyl vinyl silicone rubber, 22 parts of oxygenated soybean oil, 18 parts of styrene-butadiene rubber, 16 parts of molybdenum disulfide, 22 parts of aluminum stearate, 18 parts of cellulose acetate, 16 parts of polyester acrylic resin, 22 parts of ethoxyquinoline, paraben 18 parts of ester. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com