Waterproof and antibacterial composite functional fabric

A composite function and fabric technology, applied in the field of clothing fabrics, can solve problems such as poor compatibility, environmental and human health hazards, delamination, oil drift, etc., and achieve the effects of excellent antibacterial properties, environmental friendliness and outstanding performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In this embodiment, a waterproof and antibacterial composite functional fabric is obtained by padding a gray cloth with a waterproof finishing agent and an antibacterial finishing agent, and the gray cloth is woven from cotton warp; wherein,

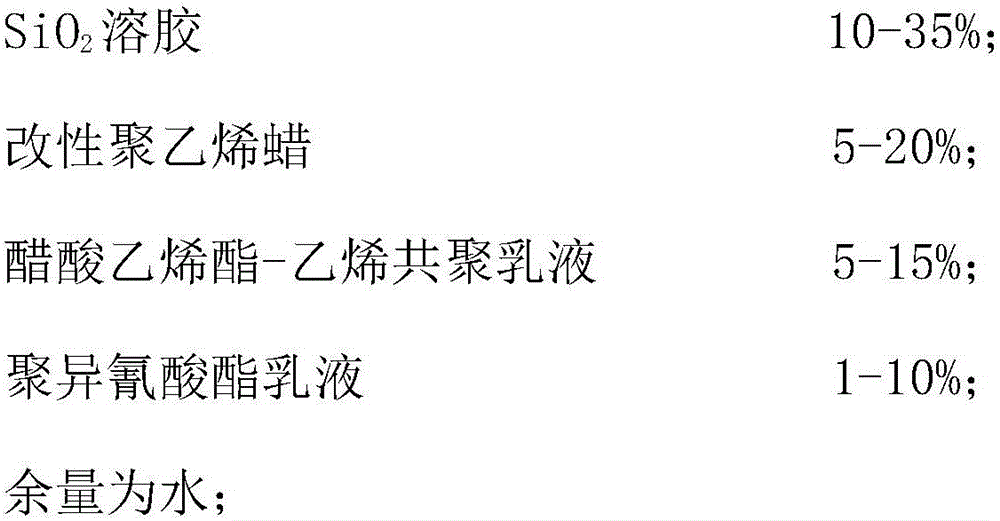

[0022] Described waterproof finishing agent comprises by weight percentage:

[0023]

[0024] The SiO 2 The sol is obtained by adding tetraethyl orthosilicate into absolute ethanol and stirring evenly, then adding ammonia water with a content of 25wt%, heating up to 80°C and stirring for 10 hours, wherein the volume ratio of tetraethyl orthosilicate, absolute ethanol, and ammonia water is 1:10:0.6;

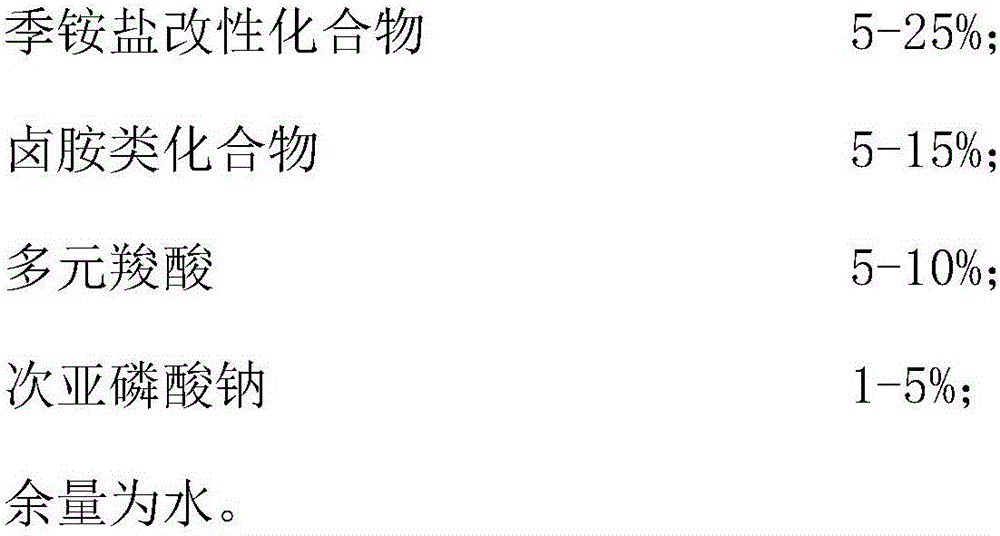

[0025] The antibacterial finishing agent comprises by weight percentage:

[0026]

[0027] The quaternary ammonium salt modified compound is a quaternary ammonium salted cyclodextrin compound, and its preparation process includes: adding cyclodextrin to isopropanol, adding a sodium hydroxide solution with a content of 25 wt%, ...

Embodiment 2

[0030] In this embodiment, a waterproof and antibacterial composite functional fabric is obtained by padding a gray cloth with a waterproof finishing agent and an antibacterial finishing agent, and the gray cloth is woven from polyester-cotton; wherein,

[0031] Described waterproof finishing agent comprises by weight percentage:

[0032]

[0033] The SiO 2 The sol is obtained by adding tetraethyl orthosilicate into absolute ethanol and stirring evenly, then adding ammonia water with a content of 30wt%, heating up to 60°C and stirring for 12 hours, wherein the volume ratio of tetraethyl orthosilicate, absolute ethanol, and ammonia water is 1:15:0.3;

[0034] The antibacterial finishing agent comprises by weight percentage:

[0035]

[0036] The quaternary ammonium salt modified compound is a quaternary ammonium salted cyclodextrin compound, and its preparation process includes: adding cyclodextrin to isopropanol, adding a sodium hydroxide solution with a content of 35%...

Embodiment 3

[0039] In this embodiment, a waterproof and antibacterial composite functional fabric, the fabric is obtained by padding a gray cloth with a waterproof finishing agent and an antibacterial finishing agent, and the gray cloth is woven from polyester; wherein,

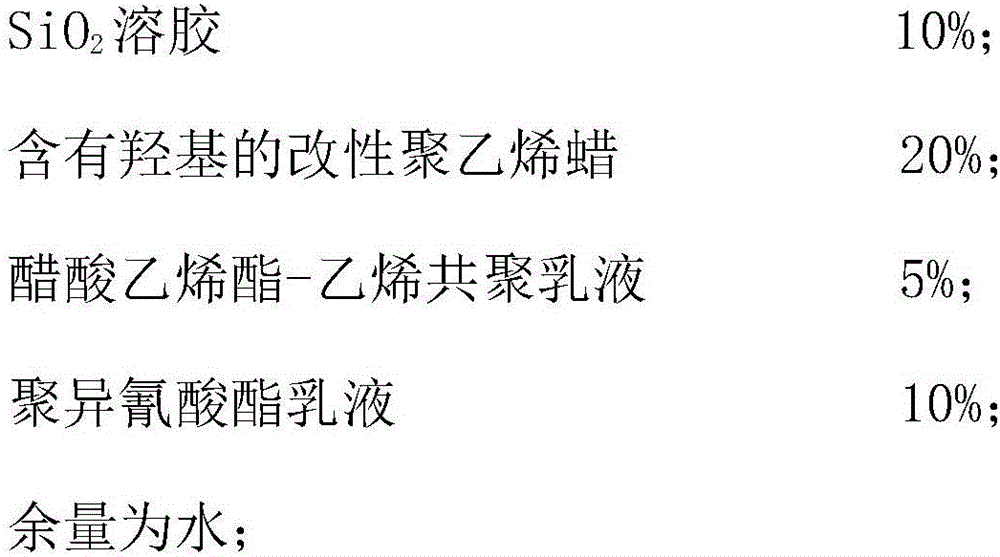

[0040] Described waterproof finishing agent comprises by weight percentage:

[0041]

[0042] The SiO 2 The sol is obtained by adding tetraethyl orthosilicate into absolute ethanol and stirring evenly, then adding ammonia water with a content of 28wt%, heating up to 70°C and stirring for 11 hours, wherein the volume ratio of tetraethyl orthosilicate, absolute ethanol, and ammonia water is 1:12:0.5; the modified polyethylene wax is a modified polyethylene wax containing a hydroxyl group and a modified polyethylene wax containing a carboxyl group;

[0043] The antibacterial finishing agent comprises by weight percentage:

[0044]

[0045]

[0046] The quaternary ammonium salt modified compound is a quaternary am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com