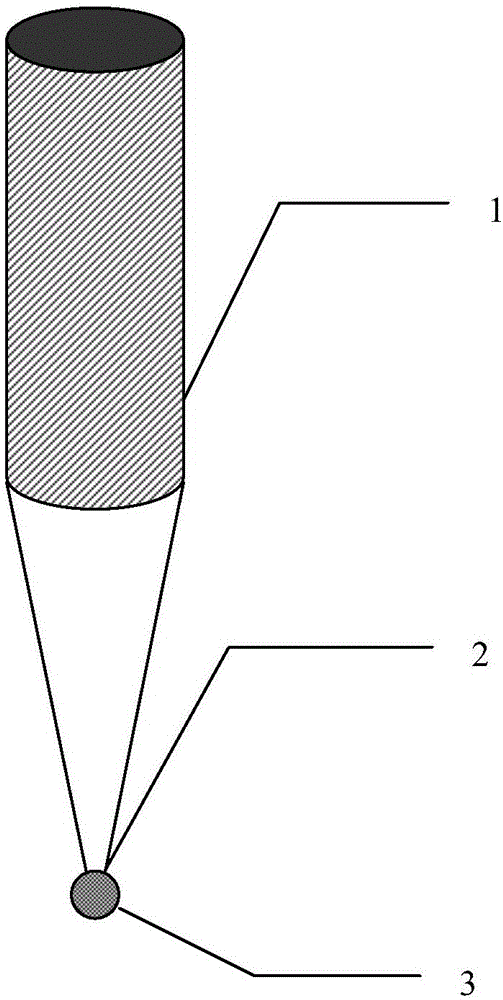

Fiber-Raman-enhanced probe based on tapered optical fiber and micro-ball lens and manufacturing method of fiber-Raman-enhanced probe

A technology of drawing a tapered optical fiber and optical fiber, which is applied in the directions of Raman scattering, material analysis by optical means, and measuring devices, can solve the problems of shallow detection depth and low spatial resolution of Raman spectrum testing, and achieves strong applicability, Improved spatial resolution and size controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

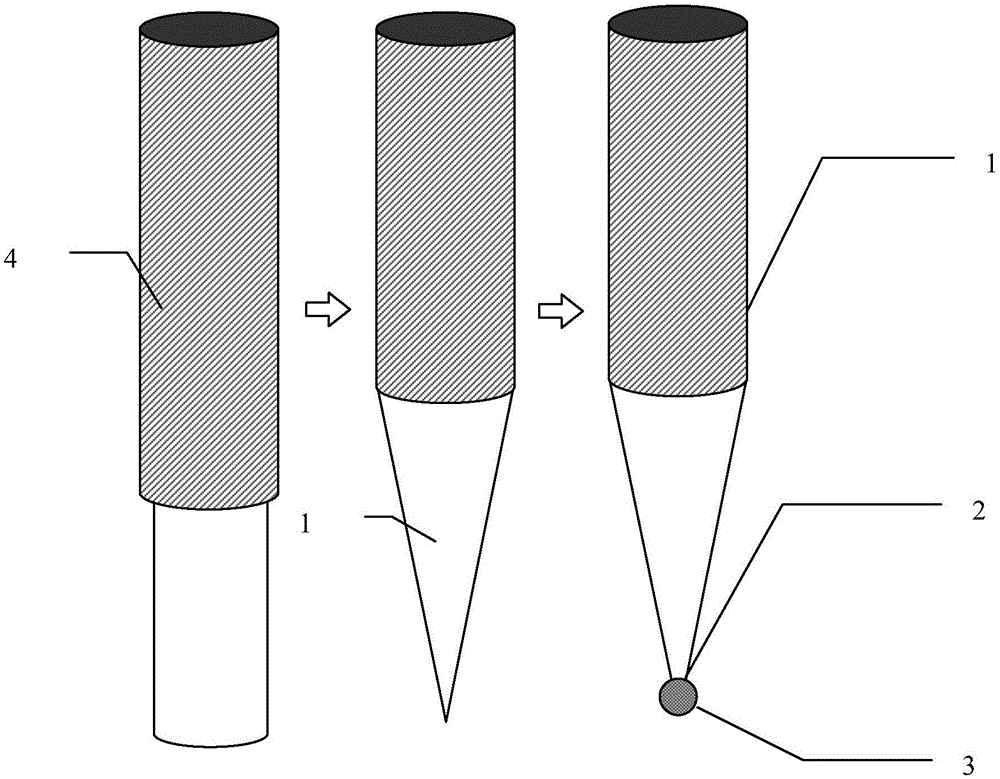

[0029] The steps of preparing the annular cavity SERS substrate are described in detail in conjunction with specific embodiments as follows:

[0030] a) Take a single-mode optical fiber (9 / 125 μm), remove the coating at one end, and clean it with acetone (purity 99.7%), alcohol (purity 99.9%), deionized water (resistivity 18.2MΩ) ultrasonic (40W) for 10 Minutes, then blow dry with nitrogen (purity 99.7%);

[0031] b) Fix the two ends of the processed optical fiber with clamps, heat with a hydrogen-oxygen flame, and stretch the optical fiber at the same time;

[0032] c) cutting the tip of the optical fiber taper with a cleaver, so that the diameter of the section is about 2 μm;

[0033] d) Configure SiO 2 Microsphere colloidal microsphere solution 2ml, where SiO 2 The diameter of the microsphere is 2 μm, the diameter deviation rate is 5%, the volume percentage concentration is 0.005%, and the solvent is deionized water;

[0034] e) SiO configured in d) 2 The solution is s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com