Fabrication method of nanometer composite phase rare-earth permanent magnet material

A rare earth permanent magnet and nanocrystalline soft magnetic technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of weakening the remanence strengthening effect, coarsening of nanocrystalline magnetic powder, etc., to suppress the growth and coarsening of grains , the effect of high residual magnetic polarization and high magnetic energy product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of the nanocomposite rare earth permanent magnet material of the present invention comprises the following steps:

[0023] Provide amorphous hard magnetic alloy powder and amorphous soft magnetic alloy powder;

[0024] Crystallize amorphous hard magnetic alloy powder into nanocrystalline hard magnetic powder, and crystallize amorphous soft magnetic alloy powder into nanocrystalline soft magnetic powder;

[0025] The nano-composite phase rare earth permanent magnetic material is obtained by spark plasma sintering nanocrystalline hard magnetic powder and nanocrystalline soft magnetic powder.

[0026] The above-mentioned hard magnetic alloy is an alloy with strong anti-demagnetization ability (high coercive force Hc), can maintain the magnetized state after magnetization, and generate a sufficiently strong and stable magnetic field around it. The hard magnetic alloy has a large coercive force (Hc) (>102A / m), a large remanence Br, a large hysteresis ...

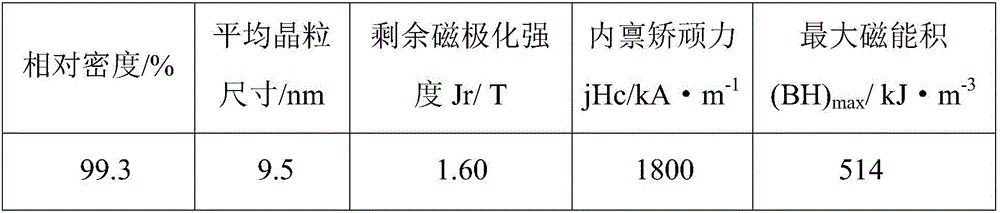

Embodiment 1

[0048] A hard magnetic phase Nd 2 Fe 14 B is the Nd of the matrix 2 Fe 14 B / α-Fe type nanocomposite rare earth permanent magnet material, its preparation method comprises the following process steps:

[0049] (1) According to the stoichiometric ratio of the chemical expression of the main phase, the raw materials are mixed: take Nd content of 10.8 at.%, Fe content of 76.2 at.%, B content of 6.4 at.%, Zr, Mo, Cr or Ti, etc. The content of trace components is 4.2at.%, to prepare Nd 2 Fe 14 Hard magnetic alloy (A alloy) raw material powder with B as the main phase; Fe content 80at.%, Ti, V, Mo and B and other trace elements content 20at.%, to prepare soft magnetic alloy whose main phase is α-Fe Raw material powder of magnetic alloy (B alloy).

[0050] (2) By means of mechanical alloying, put the prepared raw material powders of Alloy A and Alloy B together with stainless steel grinding balls into a stainless steel ball milling tank (the weight ratio of grinding balls and ra...

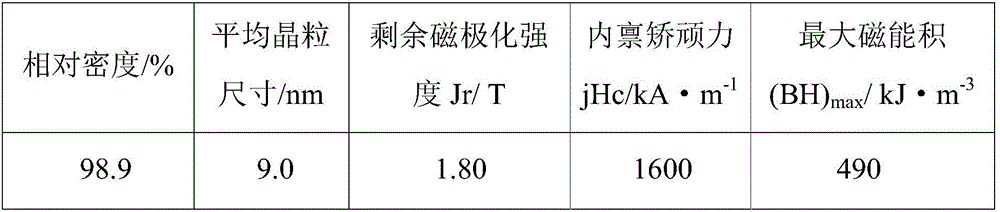

Embodiment 2

[0063] A hard magnetic phase Nd 2 Fe 14 B is the Nd of the matrix 2 Fe 14 B / Fe 3 B-type nanocomposite phase rare earth permanent magnet material, its preparation method comprises the following process steps:

[0064] (1) According to the stoichiometric ratio of the chemical expression of the main phase, the raw materials are mixed: take Nd content of 13.2 at.%, Fe content of 81.6 at.%, B content of 5.2 at.%, Zr, Mo, Cr or Ti and other trace amounts The content of components is 2.4at.%, to prepare Nd 2 Fe 14 Hard magnetic alloy (A alloy) raw material powder with B as the main phase; Fe content is 69.2 at.%, B content is 25.6 at.%, and other trace components such as V, Mo, Cr are 5.2 at.%. Prepare the main phase as Fe 3 Raw material powder of soft magnetic alloy (C alloy) of B.

[0065] (2) By means of mechanical alloying, put the prepared raw material powders of Alloy A and Alloy C together with stainless steel grinding balls into a stainless steel ball mill jar (the we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com