Poe composite backside material for photovoltaic module packaging

A technology of photovoltaic module packaging and backside materials, applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problems of loss of physical properties, and the weather resistance of fluorine-free backsheets is not as good as that of fluorine-containing backsheets, achieving comprehensive cost savings and excellent performance. Aging resistance, the effect of improving performance and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

0.066%

[0027] Mix the above materials evenly, heat and extrude a film-like product with a thickness of 0.1 mm, which is a transparent POE film with a light transmittance of 90.6%.

[0028] Element

Proportion

POE resin (melt flow index measured at 190°C is 40g / 10min, melting point is 100°C)

85%

tert-Amyl peroxy-2-ethylhexanoate

1.3%

Triallyl isocyanurate (TAIC)

0.66%

KH-550

0.26%

TINUVIN 622

0.066%

Mixture of Titanium Dioxide and Aluminum Oxide

10%

[0029] Mix the above materials evenly, heat and extrude a white film-like product with a thickness of 0.1mm, which is the opaque POE film.

[0030] Using a 0.015mm PVDF film, a layer of transparent POE film, a layer of opaque POE film and a layer of PVDF film are integrated by heating and rolling to obtain a 0.215mm thick POE composite back material.

Embodiment 2

0.39%

[0033] Mix the above materials evenly, heat and extrude a film-like product with a thickness of 0.3 mm, which is a transparent POE film with a light transmittance of 90.7%.

[0034] Element

Proportion

POE resin (melt flow index measured at 190°C is 5g / 10min, melting point is 60°C)

80%

tert-butyl peroxybenzoate (TBPB)

1.97%

Triallyl cyanurate (TAC)

1.3%

A-174

1.3%

TINUVIN 770

0.39%

Mixture of Titanium Dioxide and Aluminum Oxide

15%

[0035] Mix the above materials evenly, heat and extrude a white film-like product with a thickness of 0.3mm, which is the opaque POE film.

[0036] Using a 0.03mm PVF film, a layer of transparent POE film, a layer of opaque POE film and a layer of PVDF film are integrated by heating and rolling to obtain a 0.53mm thick POE composite back material.

Embodiment 3

0.2%

[0039] Mix the above materials evenly, heat and extrude a film-like product with a thickness of 0.2 mm, which is a transparent POE film with a light transmittance of 90.7%.

[0040] Element

Proportion

POE resin (melt flow index measured at 190°C is 5g / 10min, melting point is 60°C)

82%

1,1-bis(tert-butylperoxy)cyclohexane

1.97%

Trimethylolpropane Trimethacrylate (TMPTMA)

1.3%

Z-6030

1.3%

TINUVIN 2908

0.39%

Mixture of titanium dioxide, alumina and silica

13%

[0041] Mix the above materials evenly, heat and extrude a black film-like product with a thickness of 0.2mm, which is the opaque POE film.

[0042] Using a 0.02mm PVF film, a layer of transparent POE film, a layer of opaque POE film and a layer of PVDF film are integrated by heating and rolling to obtain a 0.42mm thick POE composite back material.

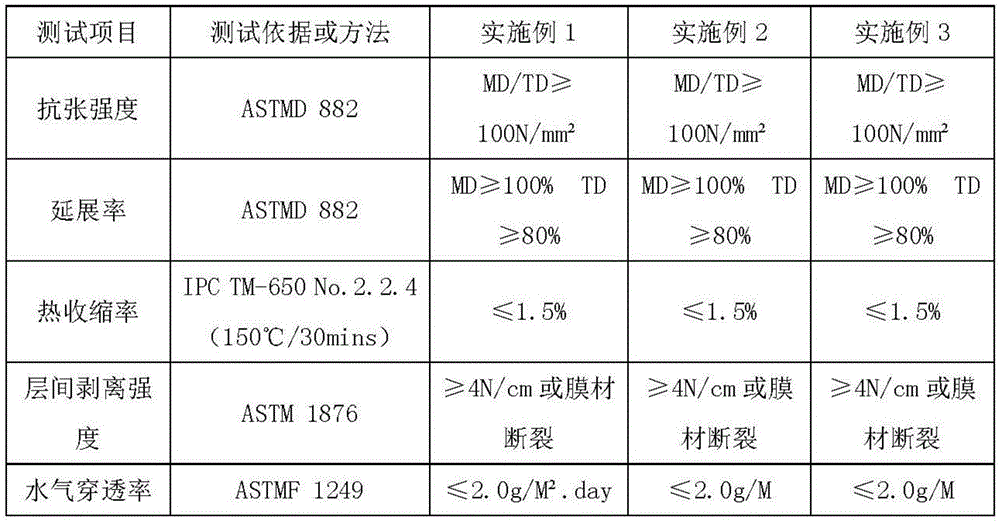

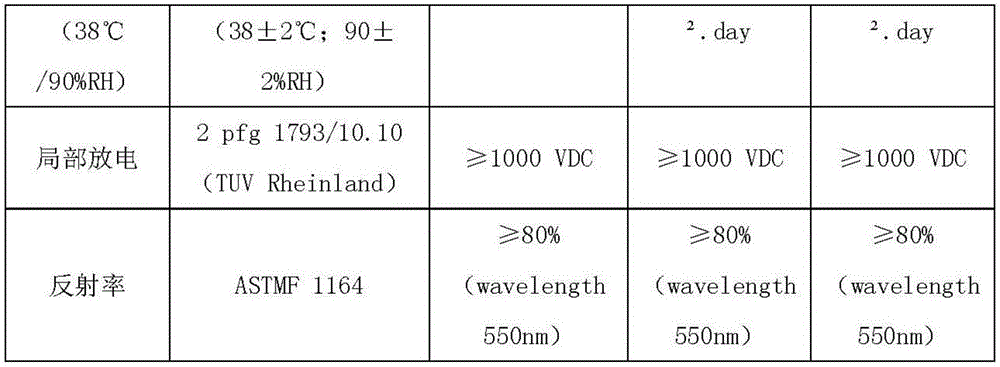

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com