Drying process of lithium iron phosphate

A technology of lithium iron phosphate and drying process, which is applied in the direction of static material dryer, granular material drying, local stirring dryer, etc. It can solve the problems of difficult control of moisture content, cumbersome process, energy consumption, etc., and shorten the output time , avoid contact with moisture, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with specific embodiments.

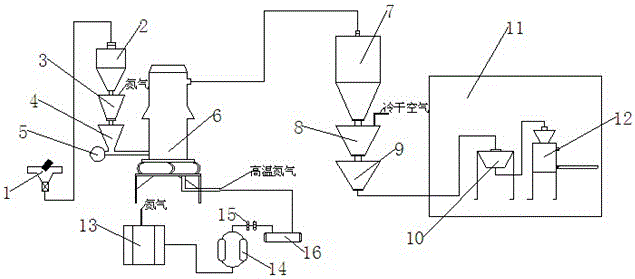

[0020] like figure 1 Shown, a kind of drying process of lithium iron phosphate comprises the following steps:

[0021] (1) Unloading: The lithium iron phosphate material is automatically turned over and unloaded by the bowl unloading machine 1, and is conveyed to the raw material storage bin 2 through the star-shaped unloading valve through positive pressure air;

[0022] (2) Crushing: The lithium iron phosphate material is sent from the raw material storage bin 2 through the star-shaped feeding valve to the nitrogen replacement bin 3 and the feeding bin 4 in sequence, and then enters the pulverizer 6 through the screw feeder 5 for pulverization, and the pulverizer 6 is a jet mill , the pulverizer 6 is a closed structure, and the pulverizer 6 is equipped with a return air system, which uses nitrogen as the air supply for the system, and uses the heated nitrogen a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com