Preparation method and application of porous bio-carrier adsorption material

A biological carrier and adsorption material technology, which is applied to the recycling and reuse of agricultural and sideline product waste, the preparation of adsorption materials, and the preparation of porous biological carrier adsorption materials, can solve the fundamental problems of crop straw, soil compaction, soil fertility, Occupying a large amount of cultivated land and other problems, to achieve the effects of adsorption, lighten the burden and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

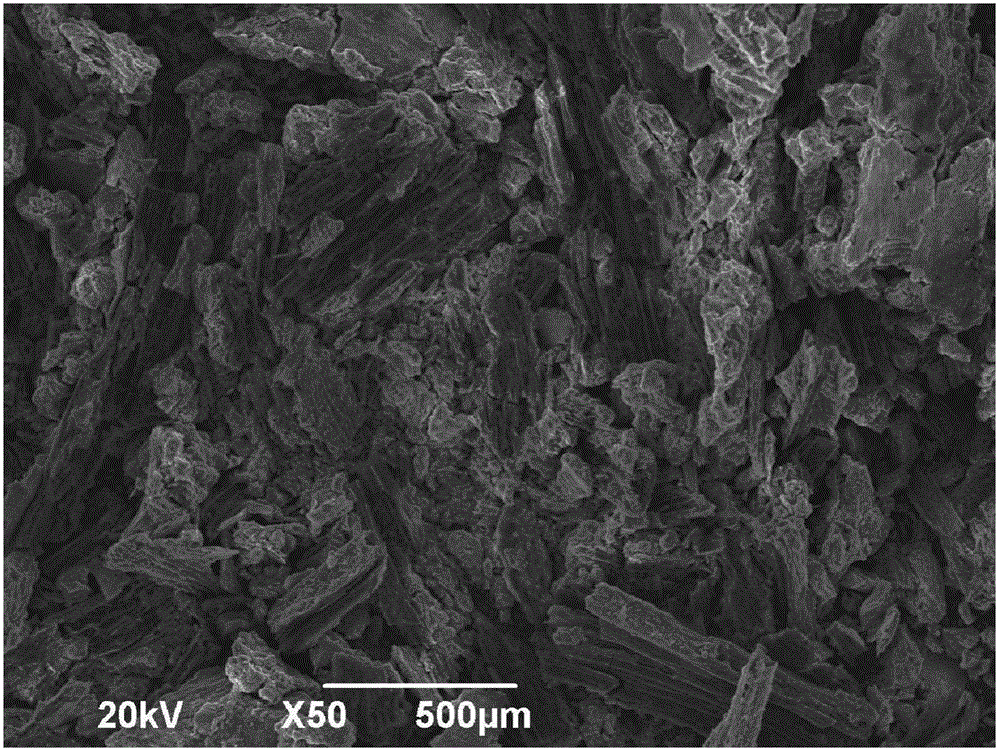

[0029] The preparation method of porous biological carrier adsorption material in the present embodiment is as follows:

[0030] 1. Crushing the wheat straw with a miniature plant pulverizer and passing through a 40-mesh sieve to obtain powder a;

[0031] 2. Pass the attapulgite and limonite powder through a 70-mesh sieve respectively to obtain attapulgite powder b and limonite powder c;

[0032] 3. Mix powder a, attapulgite powder b and limonite powder c according to a certain mass ratio, add water to granulate, control the particle size at 6-10mm, and then dry at 105°C to obtain granules; wheat straw , attapulgite and limonite mass ratio is 1:1:1.

[0033] 4. Place the obtained pellets in a high-temperature tube furnace, sinter at 600°C, 700°C, 800°C, 900°C, and 1000°C under nitrogen protection, and obtain a limonite-based Fe / C porous biological carrier after cooling Adsorbent material.

[0034] The temperature rise process of high-temperature sintering is controlled as f...

Embodiment 2

[0044] The preparation method of porous biological carrier adsorption material in the present embodiment is as follows:

[0045] 1. Crushing the wheat straw with a miniature plant pulverizer and passing through a 40-mesh sieve to obtain powder a;

[0046] 2. Pass the attapulgite and limonite powder through a 70-mesh sieve respectively to obtain attapulgite powder b and limonite powder c;

[0047] 3. Mix 100g of powder a, 100g of attapulgite powder b and 100g of limonite powder c, add water and granulate, the particle size is controlled at 6-10mm, and then dry at 105°C to obtain granules;

[0048] 4. Place the obtained pellets in a high-temperature tube furnace, sinter at a high temperature of 900° C. under nitrogen protection, and obtain a limonite-based Fe / C porous biological carrier adsorption material after cooling.

[0049] The temperature rise process of high-temperature sintering is controlled as follows: firstly, the temperature is raised from room temperature to 300°C...

Embodiment 3

[0052] The preparation method of this embodiment is the same as that of Example 1, but the powders obtained are respectively 100g powder a, 200g attapulgite powder b and 100g limonite powder c

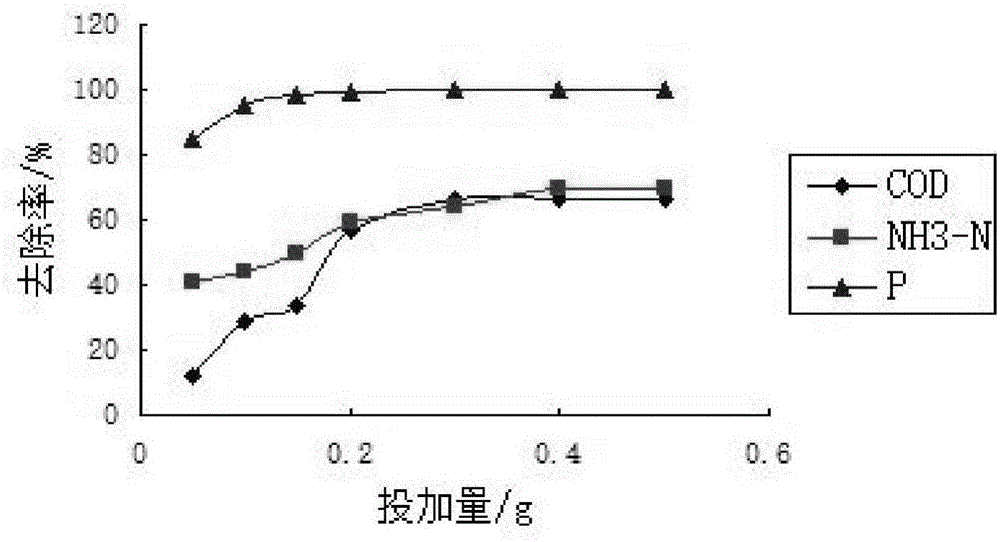

[0053] Put 50-500 mg of the porous biocarrier adsorption material prepared in this example into 50 mL of secondary effluent, control the temperature at 20-50° C., and control the shaking speed at 80-160 r / min. The absorbance was measured by molybdenum antimony anti-spectrophotometry, and the removal rate of total P was calculated.

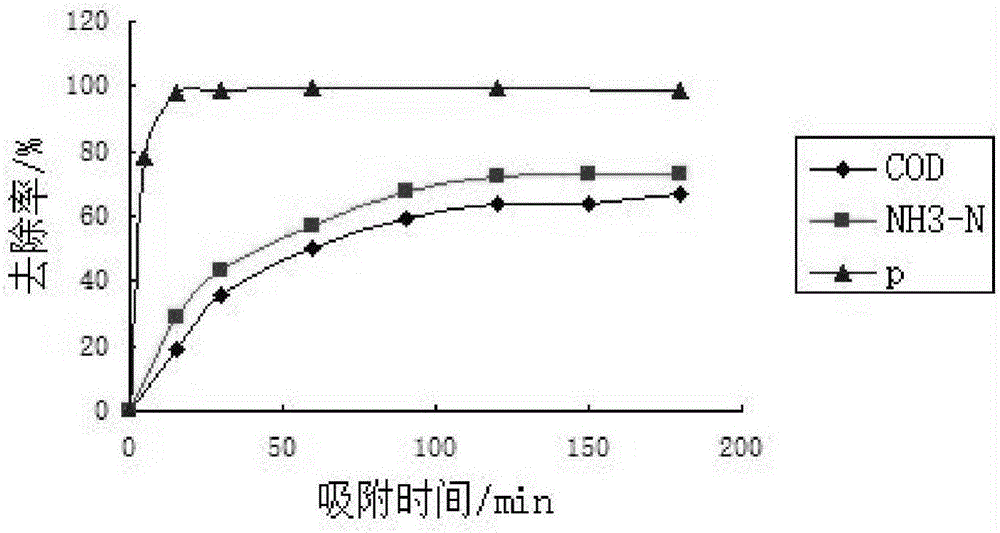

[0054] Shown by embodiment 2,3, COD and NH 3 -N can reach adsorption equilibrium within 4 hours, acidic conditions are not conducive to the adsorption of COD, NH 3 The best adsorption pH of -N is neutral, the removal rate of COD is up to 71.23%, and the removal rate of NH 3 -N removal rate is 76.56%.

[0055] It is shown from Examples 2 and 3 that when P is adsorbed, the adsorption equilibrium can be reached within 15 minutes, and the shaking speed, temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com