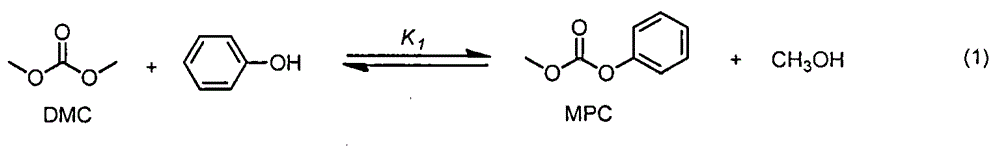

PbO/ZrO2 catalyst for synthesis of diphenyl carbonate by disproportionation of methyl phenyl carbonate

A technology of methyl phenyl carbonate and diphenyl carbonate, which is applied in the field of PbO/ZrO2 catalysts, can solve problems such as difficult recycling and reuse, and difficult product separation, and achieve the effect of good reusability and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

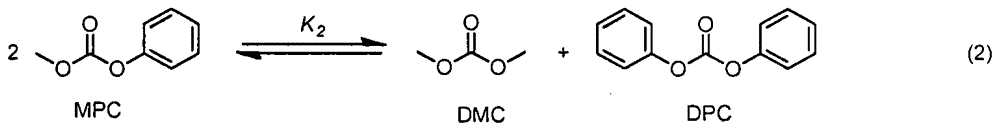

Method used

Image

Examples

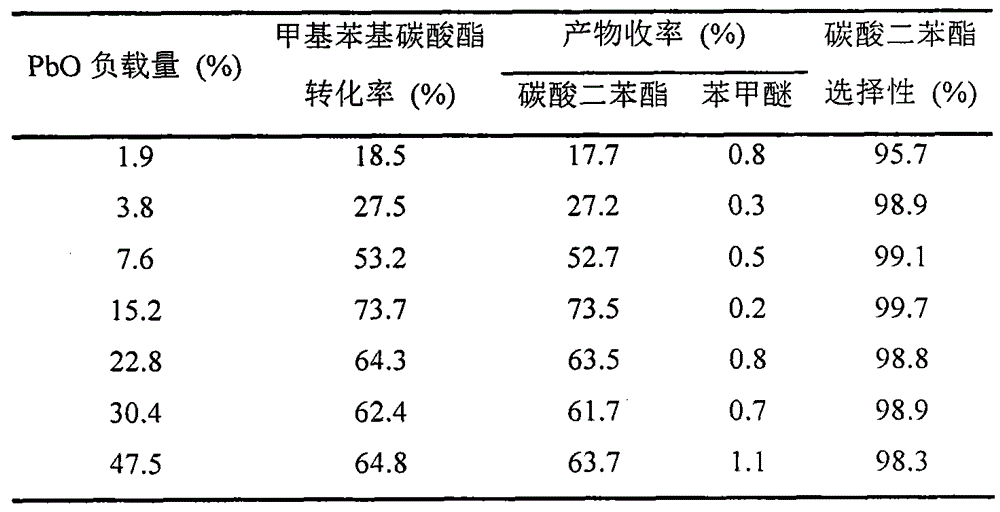

Embodiment 1

[0025] Preparation of PbO / ZrO by impregnation method 2 catalyst. Take 4.2g ZrO 2 The carrier was added to 1.12g Pb(NO 3 ) 2 In the aqueous solution, stir evenly, let it stand for 24h, dry in an oven at 110°C for 24h, and then bake at 600°C in an air atmosphere for 5h to obtain PbO / ZrO with a PbO loading of 15.2%. 2 catalyst. In a 100mL three-necked round-bottomed flask equipped with a thermometer, nitrogen conduit, rectifying column, and fractionating head, the air in the high-purity nitrogen replacement device was introduced, and then 22.8g of raw materials MPC and PbO / ZrO were added. 2 Catalyst 0.9g, slowly heat up to 200 ℃ for reaction, the dimethyl carbonate fraction is continuously distilled through the rectification column during the reaction. After the reaction, the still liquid and fractions were qualitatively analyzed by HP-6890 / 5973 gas chromatography-mass spectrometer of Hewlett-Packard Company in the United States, and the quantitative analysis was carried out...

Embodiment 2

[0027] Preparation of PbO / ZrO by Mechanical Mixing 2 catalyst. Take 4.2g ZrO 2 Carrier and 1.12g Pb(NO 3 ) 2 Mix in an agate mortar, grind evenly, and bake in air at 600°C for 5 hours to obtain PbO / ZrO with a PbO loading of 15.2%. 2 catalyst. The analysis method of disproportionation reaction condition and product is the same as embodiment 1, and the activity result of catalyst is as follows: the methyl phenyl carbonate conversion rate is 64.8%, and diphenyl carbonate selectivity is 99.5%.

Embodiment 3

[0029] Preparation of PbO / ZrO by Co-precipitation 2 catalyst. Take 11.0g ZrOCl 2 ·8H 2 O and 1.12g Pb(NO 3 ) 2 Add it into 100mL deionized water, heat to 90°C to dissolve the solid completely; under strong stirring, slowly add ammonium hydroxide dropwise until the pH of the solution reaches about 9.3, and age the white suspension at 60°C for 12h; filter , washed, dried at 110°C for 24h, and then calcined at 600°C for 5h to obtain PbO / ZrO with a PbO loading of 15.2%. 2 catalyst. The disproportionation reaction conditions and the analysis method of product are the same as embodiment 1, and the activity result of catalyst is as follows: the conversion rate of methyl phenyl carbonate is 73.7%, and the selectivity of diphenyl carbonate is 99.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com