High-dielectric-constant multi-layer ceramic capacitor medium material and preparation method thereof

A technology of dielectric materials and multilayer ceramics, applied in the field of information functional ceramic materials, to achieve the effects of high technical reliability, high dielectric constant, good application and industrialization prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

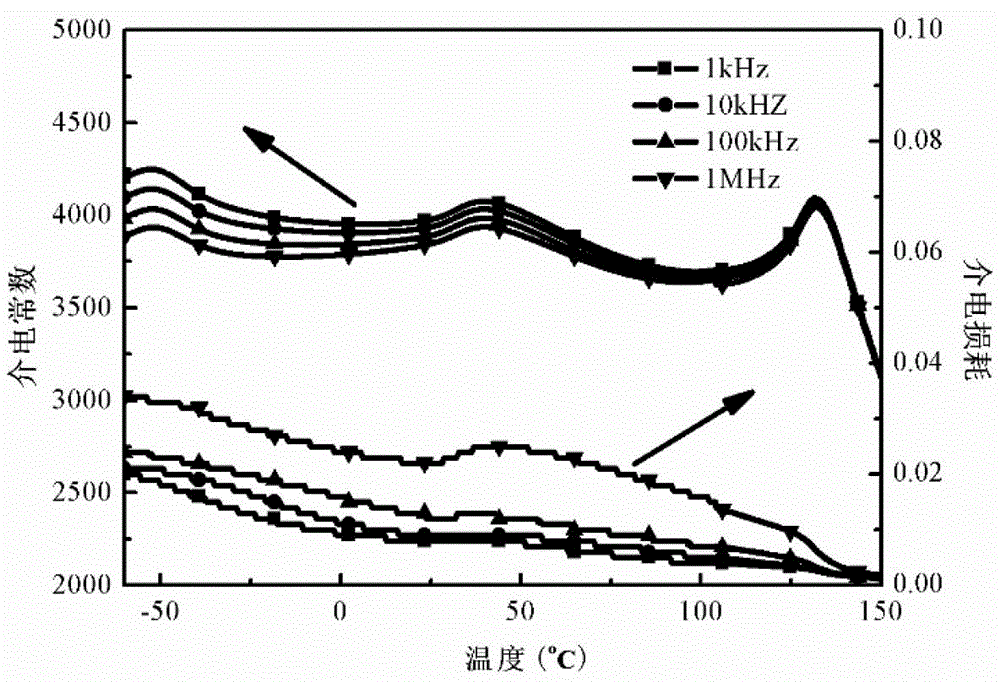

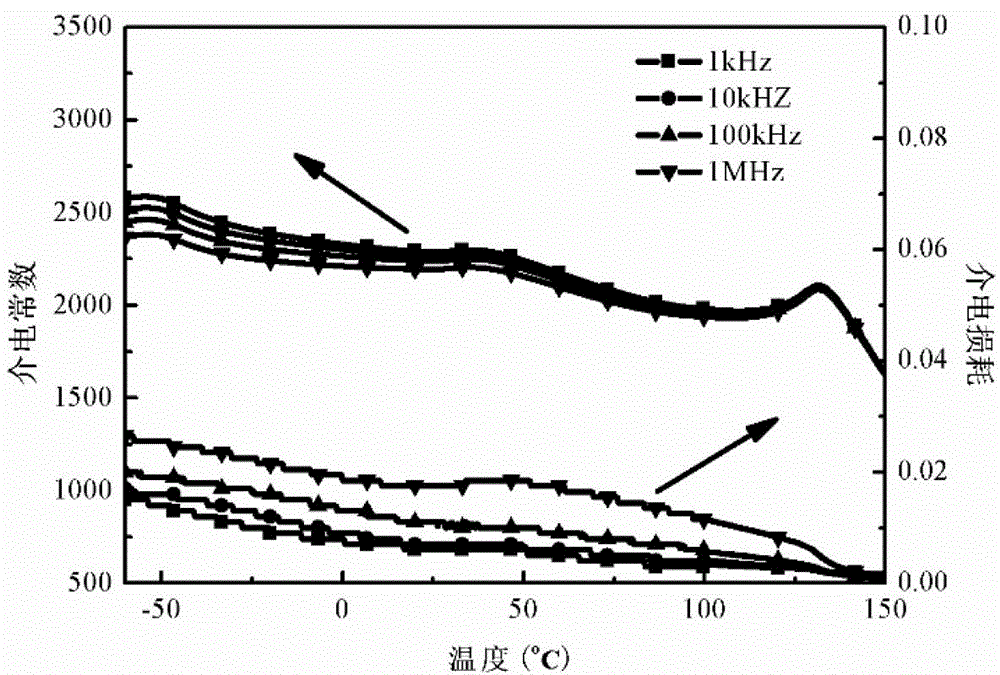

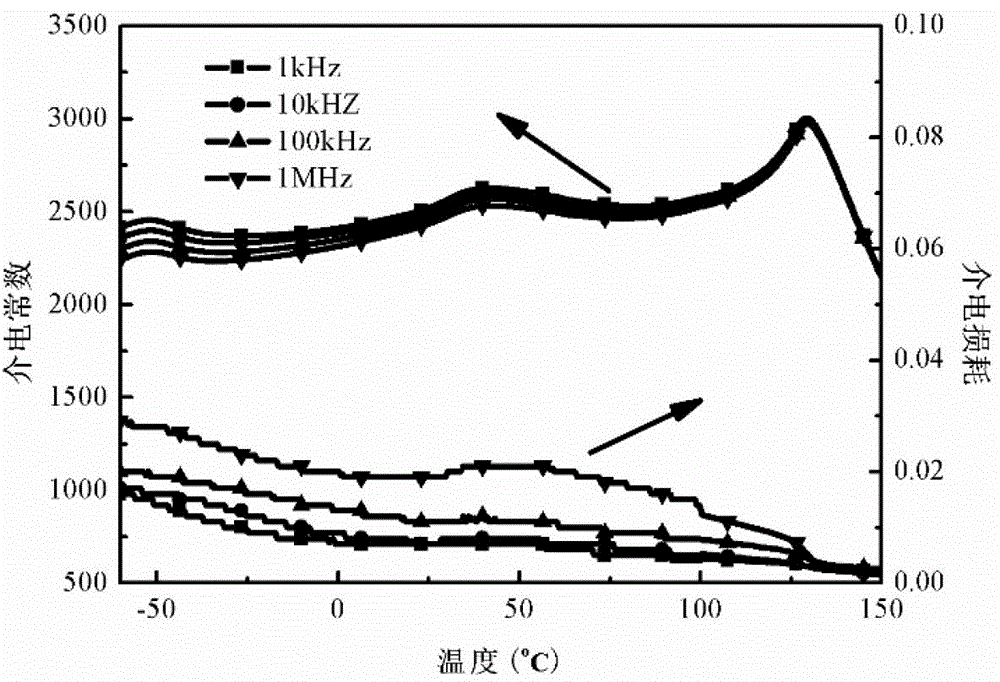

[0028] The invention discloses a high dielectric constant dielectric material for X7R and X8R type multilayer ceramic chip capacitors and a preparation method thereof. The material is Ba 1-y Ca y Ti 1-x Zr x o 3 (0≤x≤0.05,0≤y≤0.05) as base material, its molar content is 80%~96%, and then (Na 0.52 K 0.48 ) 1-m Li m NbO 3 (01-y Ca y Ti 1-x Zr x o 3 -n(Na 0.52 K 0.48 ) 1- mLi m NbO 3 (0.04≤n≤0.2). The preparation method adopted is a solid-phase synthesis method, which mainly includes process steps such as batching, pre-sintering synthesis, ball milling, molding, sintering, and electrode. The temperature characteristics of the dielectric material in the invention meet the requirements of X7R and X8R, the highest dielectric constant at room temperature is ~4000, and the dielectric loss is ~0.8%.

[0029] The Ba 1-y Ca y Ti 1-x Zr x o 3 The matrix material is based on BaCO 3 , CaCO 3 ,TiO 2 and ZrO 2 It is synthesized by high-temperature calcination of r...

Embodiment 1

[0048] First according to the chemical formula Ba 1-y Ca y Ti 1-x Zr x o 3 (x=y=0) Calculate the mass ratio of raw materials, and weigh BaCO respectively with electronic scales 3 (purity 99.76%), TiO 2 (purity 98.81%), using absolute ethanol as a ball milling dispersant, planetary ball milling for 6 hours, after drying, pre-calcining at 1150 ° C for 2 hours to synthesize the base material BaTiO 3 (x=y=0). Then the powder was ball milled for 6 hours, and dried to obtain dry BaTiO 3 Fine powder. According to the chemical formula (Na 0.52 K 0.48 ) 0.94 Li 0.06 NbO 3 (m=0.06) Calculate the mass ratio of raw materials, use the electronic balance scale Na 2 CO 3 (purity 99.8%), K 2 CO 3 (purity 99.0%), Li 2 CO 3 (purity 98.0%), Nb 2 o 5 (purity 99.5%) was mixed ball milled, after drying, pre-calcined at 800° C. for 5 hours, followed by planetary ball milling for 6 hours and high-energy ball milling for 4 hours, and drying to obtain dry fine powder. According to ...

Embodiment 2

[0050] The values of x, y, m, n, sintering temperature, and holding time are shown in Table 1, and the preparation steps and other parameters are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com