Potlife-adjustable wind turbine blade coating and preparation method thereof

A technology for wind turbine blades and pot life, which is applied in the direction of fireproof coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as pot life instructions, achieve the effects of improving viscosity, overcoming excessively fast reaction rates, and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

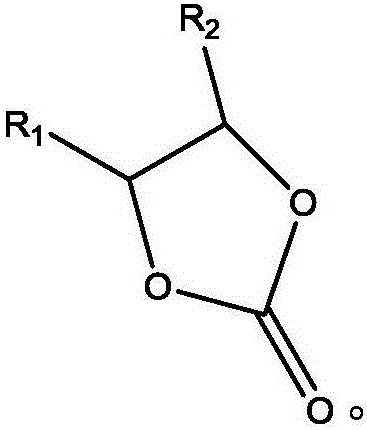

Method used

Image

Examples

Embodiment 1

[0049] The first and second components of embodiment 1 are used in conjunction with first: second=5.2:1 (mass ratio);

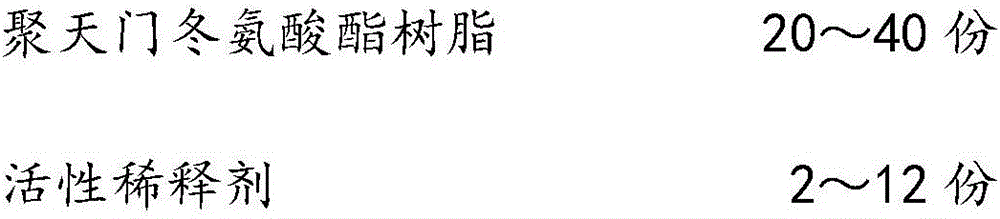

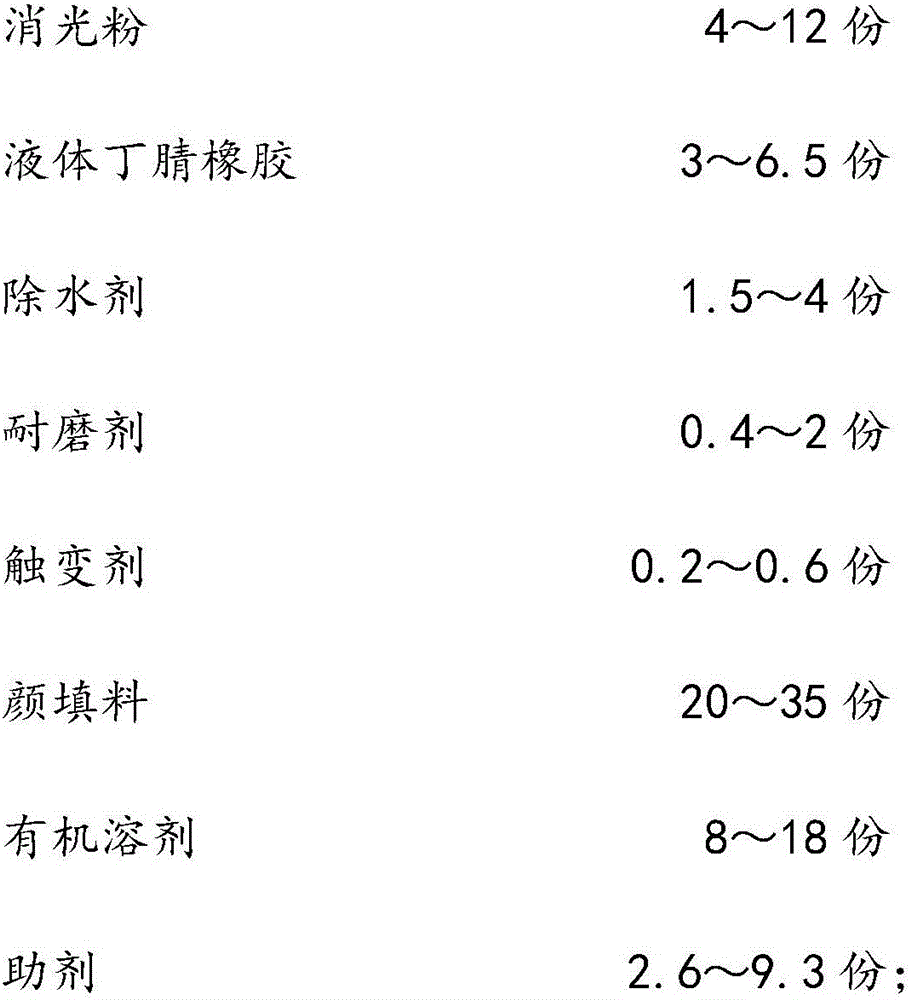

[0050] The preparation method of component A is: 23 parts of polyaspartic acid ester resin, 1.2 parts of light stabilizer, 0.8 parts of ultraviolet absorber, 2.2 parts of wetting and dispersing agent, 0.3 parts of defoaming agent, 1.4 parts of leveling agent, 1.8 parts of coupling agent, 1.8 parts of anti-wear agent, 6.5 parts of liquid nitrile rubber, 7 parts of active diluent, mix and stir evenly; under stirring at a speed lower than 600rpm, add 0.3 parts of thixotropic agent, 30 parts of pigments and fillers, Disperse until it is in a uniform state, grind for 50 to 100 minutes; add 16 parts of organic solvent, 6 parts of matting powder, and 1.7 parts of water remover, disperse at a speed lower than 600rpm for 10 to 15 minutes, and obtain a uniform state by filtering finished product;

[0051] The preparation method of component B is as follows: 94 parts o...

Embodiment 2

[0052] The first and second components of embodiment 2 are used in conjunction with first: second=3.6:1 (mass ratio);

[0053] The preparation method of component A is: 30 parts of polyaspartic acid ester resin, 0.9 parts of light stabilizer, 0.4 parts of ultraviolet absorber, 1.5 parts of wetting and dispersing agent, 0.2 parts of defoaming agent, 0.5 parts of leveling agent, 0.9 parts of coupling agent, 0.7 parts of anti-wear agent, 3 parts of liquid nitrile rubber, 9 parts of active diluent, mix and stir evenly; under stirring at a speed lower than 600rpm, add 0.4 parts of thixotropic agent, 33 parts of pigments and fillers, Disperse until it is in a uniform state, grind for 50 to 100 minutes; add 9.6 parts of organic solvent, 7 parts of matting powder, and 2.9 parts of water remover, disperse at a speed lower than 600rpm for 10 to 15 minutes, and obtain a uniform state by filtering finished product;

[0054] The preparation method of component B is as follows: 98 parts of...

Embodiment 3

[0055] The first and second components of embodiment 3 are used in conjunction with first: second=2.9:1 (mass ratio);

[0056] The preparation method of component A is: 37 parts of polyaspartic acid ester resin, 3 parts of light stabilizer, 0.3 part of ultraviolet absorber, 0.9 part of wetting and dispersing agent, 0.4 part of defoaming agent, 0.7 part of leveling agent, 1.3 parts of coupling agent, 0.4 parts of anti-wear agent, 3 parts of liquid nitrile rubber, 11 parts of active diluent, mix and stir evenly; under stirring at a speed lower than 600rpm, add 0.3 parts of thixotropic agent, 21 parts of pigments and fillers, Disperse until it is in a uniform state, grind for 50-100 minutes; add 10.6 parts of organic solvent, 11 parts of matting powder, and 1.6 parts of water-removing agent, disperse at a speed lower than 600rpm for 10-15 minutes, and obtain a uniform state by filtering finished product;

[0057] The preparation method of component B is as follows: 98 parts of i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com