Integrated control system for automobile exhaust emission

A technology that integrates control systems and automobile exhaust, and is applied in exhaust devices, air quality improvement, and noise reduction devices. problems, to facilitate disassembly, inspection and testing, to avoid the influence of high temperature baking, and to facilitate inspection and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

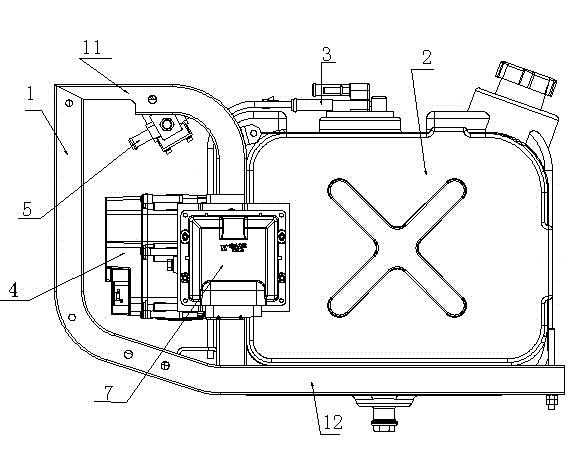

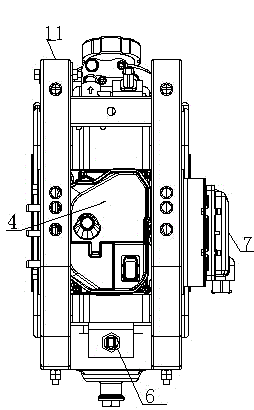

[0017] The present invention as figure 1 , 2 shown.

[0018] An integrated control system for automobile exhaust emissions, comprising a bracket assembly 1, the bottom side of the bracket assembly 1 is extended as a bracket 12, and the other side is a frame structure 11, and a urea tank 2 is arranged on the bracket 12, and the urea tank 2 The top of the tank is provided with a liquid level sensor assembly 3, the side of the urea tank 2 is in contact with the frame structure 11, and a U-shaped fixing plate is arranged at the gap of the frame structure 11, and a urea metering pump 4 is arranged on the U-shaped fixing plate , the exhaust hole is fixed downward; the frame structure 11 above the urea metering pump 4 is provided with a heating solenoid valve 5; the frame structure 11 below the urea metering pump 4 is in the neutral position or two The side is provided with an ambient temperature sensor 6 as required; the sides of the frame structure 11 are respectively installed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com