Non-contact type fluid electric impedance measurement device and method based on digital phase sensitive demodulation virtual inductance technology

A technology of digital phase-sensitive demodulation and virtual inductance, which is applied in the direction of fluid resistance measurement, etc., can solve the problems of detecting adverse effects, slow calculation speed, and difficult adjustment of inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

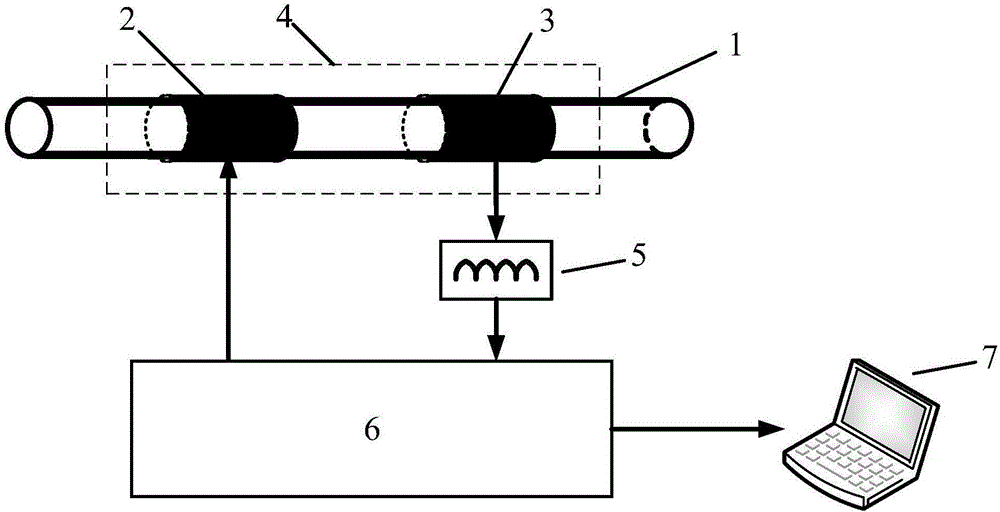

[0059] Such as figure 1 As shown, the excitation electrode 2 and the detection electrode 3 are sequentially installed on the outer wall of the insulated measurement pipe 1, the metal shield 4 is placed around the excitation electrode 2 and the detection electrode 3, the signal processing is connected with the communication module 6 and the excitation electrode 2, and the detection electrode 3 is connected with the input end of the virtual inductance module 5, the output end of the virtual inductance module 5 is connected with the signal processing and communication module 6, and finally the signal processing and communication module 6 is connected with the microcomputer 7 through the USB data line.

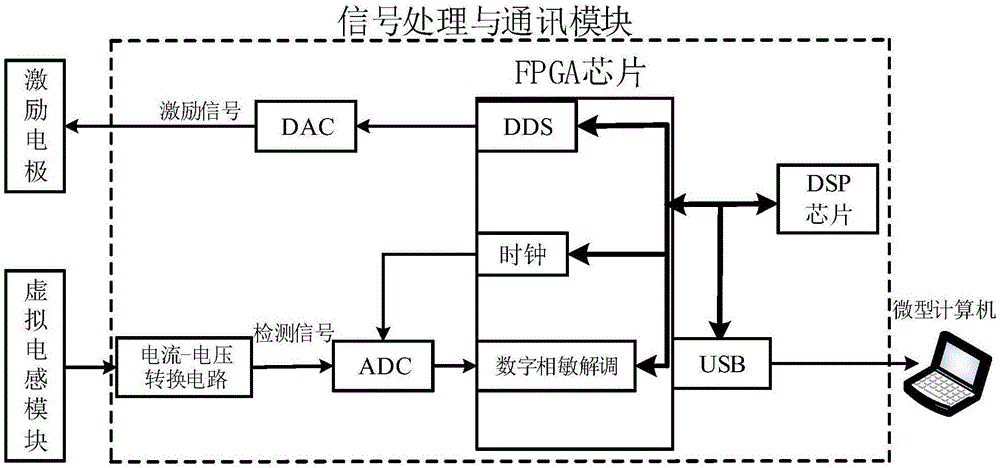

[0060] The process of measuring fluid electrical impedance with this device and method is as follows: the signal processing and communication module 6 generates a sinusoidal excitation signal of a specific frequency and applies it to the excitation electrode 2, and the current sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com