Magnetically anisotropic rare earth iron boron permanent magnet alloy submicron particles and preparation method thereof

A magnetic anisotropy, sub-micron particle technology, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problems of low particle yield, difficult to control the morphology, and reduce to less than one micron, etc. Achieve the effect of low cost and good application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A method for preparing rare earth-iron-boron permanent magnet alloy submicron particles with magnetic anisotropy, comprising the following steps:

[0034] 1) Heat-treat the isotropic rare earth-iron-boron fast-quenching strip in an oxygen-free environment at 500°C to 900°C until the average grain size grows to 0.1-1 μm; the heat treatment time is 0.5h-10h ;

[0035] 2) Under the hydrogen pressure of 250℃~350℃ and 50kPa~500kPa, hydrogen absorption treatment is carried out; then dehydrogenation treatment is carried out at 250℃~350℃; the dehydrogenation treatment is mainly carried out by vacuuming, and the dehydrogenation treatment can remove the main phase, hydrogen in the rare earth-rich phase at the grain boundaries remains in it;

[0036] 3) Place the quenched strips obtained in step 2) in a ball milling jar with balls, add a surfactant and an organic solvent, seal the ball milling jar under the protection of an inert gas, put the ball milling jar into a ball mill for...

Embodiment 1

[0045] A method for preparing neodymium-iron-boron permanent magnet alloy submicron particles with magnetic anisotropy, comprising the following steps:

[0046] 1) Annealing the isotropic Nd-Fe-B quenched strip in an oxygen-free environment at 750°C for 1 h;

[0047] 2) At 320°C, under a hydrogen pressure of 300kPa, perform hydrogen absorption treatment; then at 320°C, vacuumize for dehydrogenation treatment;

[0048] 3) Get 10 grams of neodymium-iron-boron quick-quenching strips through the above-mentioned treatment and put them into a ball mill jar with grinding balls. The mass ratio of the strips is 10:1; add 10 grams of oleylamine and n-heptane to fill up the ball mill jar, seal the ball mill jar and put it into a planetary ball mill for ball milling. The rotation rate of the planetary ball mill is 300 rpm.

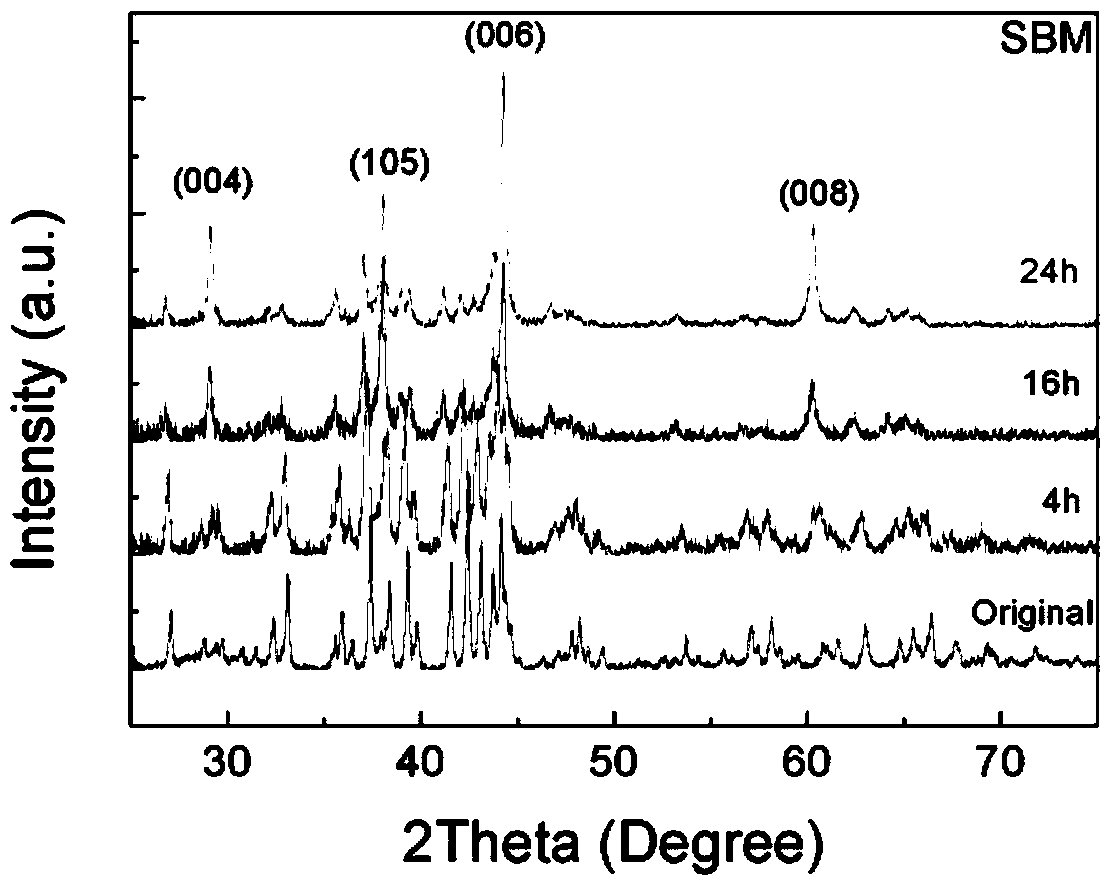

[0049] 4) After ball milling for 4h, 16h, and 24h, part of the products were taken out and ultrasonically cleaned in n-hexane for 20min, dried in a vacuum environme...

Embodiment 2

[0053] A method for preparing neodymium-iron-boron permanent magnet alloy submicron particles with magnetic anisotropy, comprising the following steps:

[0054] 1) Annealing the isotropic Nd-Fe-B quenched strip in an oxygen-free environment at 900°C for 0.5h;

[0055] 2) At 300°C, under a hydrogen pressure of 200kPa, perform hydrogen absorption treatment; then at 300°C, vacuumize for dehydrogenation treatment;

[0056] 3) Get 10 grams of neodymium-iron-boron quick-quenching strips through the above-mentioned treatment and put them into a ball mill jar with grinding balls. The mass ratio of the strips is 5:1; add 20 grams of oleic acid and absolute ethanol to fill up the ball mill jar, seal the ball mill jar and put it into a planetary ball mill for ball milling. The rotation rate of the rolling ball mill is 300 rpm.

[0057] 4) After ball milling for 8 hours, some products were taken out and ultrasonically cleaned in n-hexane for 20 minutes, dried in a vacuum environment, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com