NiSe-Ni3Se2 porous nanosphere material used for supercapacitor and preparation method for material

A technology of supercapacitors and nanospheres, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of less research and application of supercapacitors, and achieve a low-cost, short-process suitable for large-scale production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Cut the nickel foam into a size of 4cm×2cm, and put it in a 3 mol L -1 In the hydrochloric acid solution, ultrasonically react for 30 minutes to remove the NiO layer on the surface, and wash the treated nickel foam with deionized water and ethanol until neutral.

[0036] (2) Weigh 1mmol of nickel nitrate hexahydrate and 1mmol of selenium dioxide as raw materials and dissolve them in 40mL of water, and stir for 30min to obtain a precursor solution.

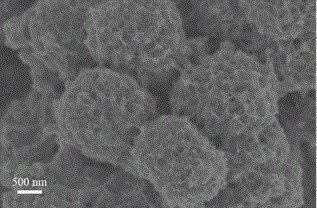

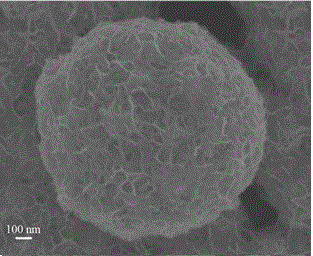

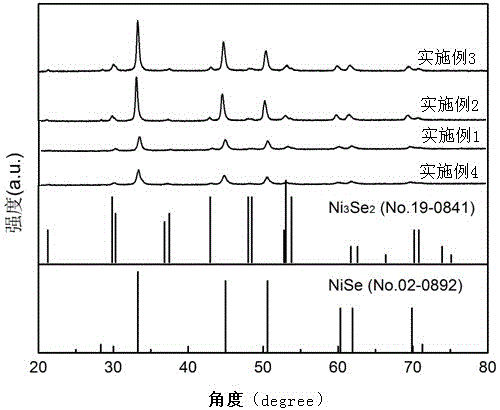

[0037] (3) Pour the above precursor solution into a polytetrafluoroethylene hydrothermal reaction kettle, place the nickel foam treated in step (1) in it, put the reaction kettle into a drying oven, and react at 180°C for 2 hours, After cooling the reactor to room temperature, collect foamed nickel, wash with ethanol and deionized water respectively, and dry to obtain NiSe-Ni based on foamed nickel. 3 Se 2 Porous nanosphere supercapacitor materials.

Embodiment 2

[0039] (1) Cut the nickel foam into a size of 4cm×2cm, and put it in a 3 mol L -1 In the hydrochloric acid solution, ultrasonically react for 30 minutes to remove the NiO layer on the surface, and wash the treated nickel foam with deionized water and ethanol until neutral.

[0040] (2) Weigh 1mmol of nickel nitrate hexahydrate and 1mmol of selenium dioxide as raw materials and dissolve them in 40mL of water, and stir for 30min to obtain a precursor solution.

[0041] (3) Pour the above precursor solution into a polytetrafluoroethylene hydrothermal reaction kettle, place the nickel foam treated in step (1) in it, put the reaction kettle into a drying oven, and react at 180°C for 4 hours, After cooling the reactor to room temperature, collect foamed nickel, wash with ethanol and deionized water respectively, and dry to obtain NiSe-Ni based on foamed nickel. 3 Se 2 Porous nanosphere supercapacitor materials.

Embodiment 3

[0043] (1) Cut the nickel foam into a size of 4cm×2cm, and put it in a 3 mol L -1 In the hydrochloric acid solution, ultrasonically react for 30 minutes to remove the NiO layer on the surface, and wash the treated nickel foam with deionized water and ethanol until neutral.

[0044] (2) Weigh 1mmol of nickel nitrate hexahydrate and 1mmol of selenium dioxide as raw materials and dissolve them in 40mL of water, and stir for 30min to obtain a precursor solution.

[0045] (3) Pour the above precursor solution into a polytetrafluoroethylene hydrothermal reaction kettle, place the nickel foam treated in (1) in it, put the reaction kettle into a drying oven, and react at 160°C for 6 hours, and then Cool the reactor to room temperature, collect foamed nickel, wash with ethanol and deionized water respectively, and dry to obtain NiSe-Ni based on foamed nickel 3 Se 2 Porous nanosphere supercapacitor materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com