Super-junction power device and fabrication method thereof

A technology of a power device and a manufacturing method, applied in the field of superjunction power devices and their manufacturing, can solve the problems affecting the surface breakdown strength, the reduction of the ion concentration, the reduction of the breakdown voltage, etc., so as to reduce the area of the partial pressure region and improve the ion concentration. , the effect of electric field spike enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

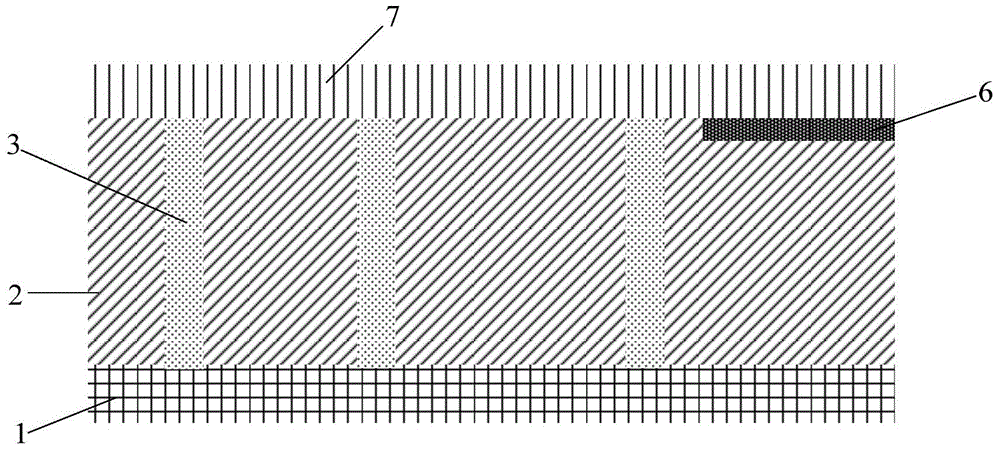

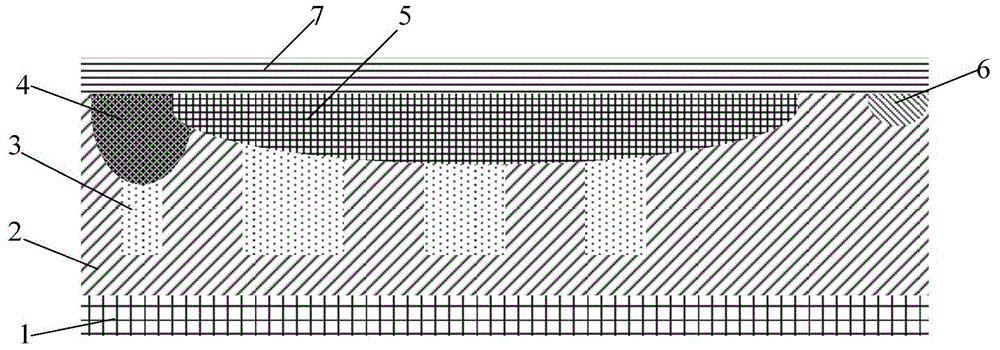

[0029] Such as figure 1 As shown, the super junction power device of this embodiment includes an active area, a voltage dividing area, a stop ring area and a scribe lane area, the voltage dividing area is set on the periphery of the active area, and the stop ring area is set on the periphery of the active region, the scribe lane region is disposed on the periphery of the stop ring region,

[0030] The voltage dividing region includes a plurality of P pillars 3 with the same pitch, and the width of the P pillars 3 gradually decreases from the active region to the stop ring.

[0031] The voltage division region of the super junction power device adopts P columns 3 with different widths to reduce the surface electric field intensity of the power device, so that the concentration of P-type ions per unit area changes, thereby increasing the surface ion concentration in the voltage division region, reducing The influence of the electric field accumulated on the surface of the oxide...

Embodiment 2

[0040] The present invention also provides a method for manufacturing a super junction power device, comprising the following steps:

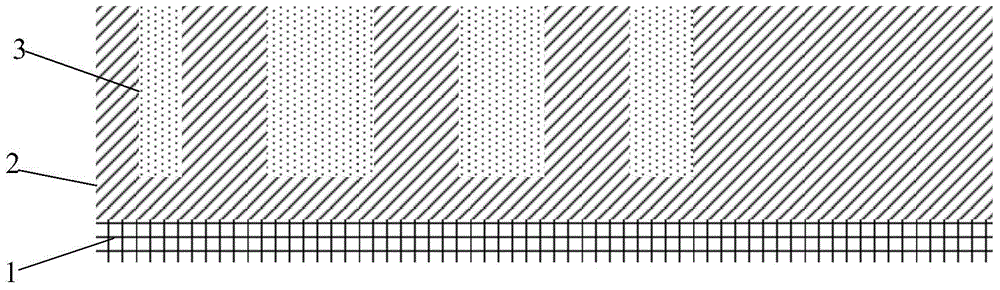

[0041] Step 1, as shown in Figure 3 (a), a substrate is provided, the substrate includes a silicon wafer 1 and an N-type epitaxial layer 2, and a P pillars, wherein the width of the P pillars 3 in the active region is equal, and the width of the P pillars 3 in the partial pressure region gradually decreases from the active region to the direction of the stop ring region; the ion concentration of the P pillars 3 is the same .

[0042] The manufacturing method of the present invention adopts P pillars 3 with different widths in the partial pressure region to reduce the surface electric field intensity of the power device, so that the P-type ion concentration per unit area changes, thereby increasing the surface ion concentration in the partial pressure region and reducing the electric field intensity of the power device. The influence of the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com