A kind of preparation method of nano wo3/tio2-iron modified zeolite composite photocatalyst

A composite light and catalyst technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of inconvenient disassembly and recycling, low efficiency of photogenerated carriers, and low utilization rate, etc. The effect of improving efficiency, good degradation effect and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

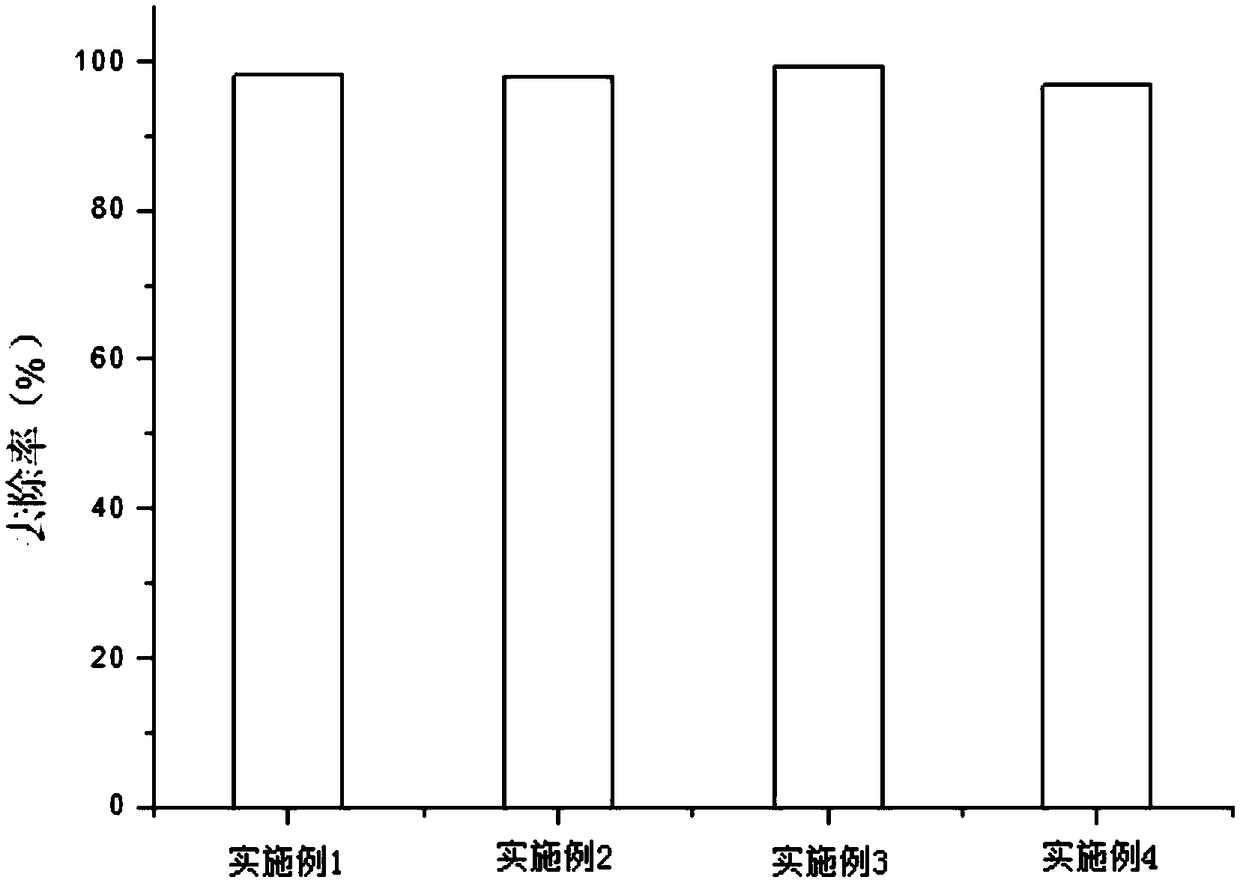

Examples

Embodiment 1

[0030] Nano WO in this embodiment 3 / TiO 2 -The preparation method of iron-modified zeolite composite photocatalyst, specifically comprises the following steps:

[0031] (1) Disperse 5 g of artificial zeolite A in 50 mL of 10 mol / L NaOH solution, and stir at 100 ° C for 1 hour to form a zeolite precursor;

[0032] (2) Preparation of nano-WO 3 (20nm particle size) and TiO 2 (particle size is 20nm) mixed aqueous solution, and then fully mixed with the zeolite precursor to prepare a mixed gel;

[0033] (3) subjecting the mixed gel to crystallization treatment, and after the crystallization is completed, the intermediate is obtained through separation, washing and drying;

[0034] (4) The intermediate is fully mixed with 50 mL of 4mol / L ferric chloride solution, separated, washed and dried, and then calcined at a high temperature to obtain the nano-WO 3 / TiO 2 - Iron-modified zeolite composite photocatalyst.

[0035] In step (1), the amount of zeolite added in the alkali so...

Embodiment 2

[0041] Nano WO in this embodiment 3 / TiO 2 -The preparation method of iron-modified zeolite composite photocatalyst, specifically comprises the following steps:

[0042] (1) Disperse 10 g of artificial zeolite X in 100 mL of 12 mol / L NaOH solution, and stir at 120 ° C for 3 hours to form a zeolite precursor;

[0043] (2) Preparation of nano-WO 3 (particle size is 40nm) and TiO 2 (particle size is 40nm) mixed aqueous solution, and then fully mixed with the zeolite precursor to prepare a mixed gel;

[0044] (3) subjecting the mixed gel to crystallization treatment, and after the crystallization is completed, the intermediate is obtained through separation, washing and drying;

[0045](4) The intermediate is fully mixed with 100 mL of 5 mol / L ferric nitrate solution, separated, washed and dried, and then calcined at a high temperature to obtain the nano-WO 3 / TiO 2 - Iron-modified zeolite composite photocatalyst.

[0046] In step (1), the amount of zeolite added in the alk...

Embodiment 3

[0052] Nano WO in this embodiment 3 / TiO 2 -The preparation method of iron-modified zeolite composite photocatalyst, specifically comprises the following steps:

[0053] (1) Add the silicon source and the aluminum source into the alkali solution, mix well, and react at 150°C for 3 hours to prepare the zeolite precursor;

[0054] (2) Nano WO 3 (30nm particle size) and TiO 2 (particle size is 30nm) is added in the zeolite precursor, fully mixed, and mixed gel is obtained;

[0055] (3) subjecting the mixed gel to crystallization treatment, and after the crystallization is completed, the intermediate is obtained through separation, washing and drying;

[0056] (4) The intermediate is fully mixed with the iron salt solution, separated, washed and dried, and then calcined at a high temperature to obtain the nano-WO 3 / TiO 2 - Iron-modified zeolite composite photocatalyst.

[0057] In step (1), the molar ratio of silicon source, aluminum source and alkali solution is 1:2:200. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com