Method for preparing graphite paper/ carbon nano tube-graphene/ polyaniline flexible composite electrode

A carbon nanotube and composite electrode technology, which is applied in the fields of hybrid capacitor electrodes and hybrid/electric double layer capacitor manufacturing, etc., can solve the problems of inability to participate in electrochemical energy storage, difficult electrolyte ions, low energy density, etc., and achieve thermal stability. and high chemical stability, excellent electrical conductivity, and the effect of improving specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

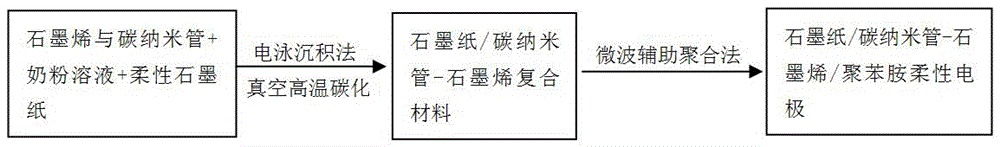

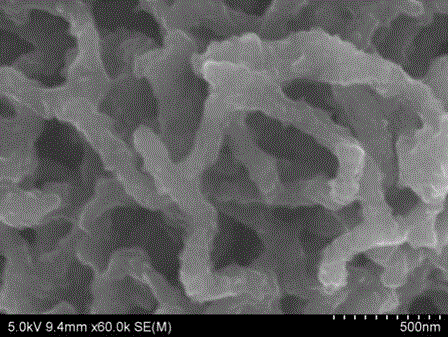

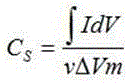

[0058] Graphite paper is used as an electrode, and is immersed in the highly dispersed graphene and carbon nanotube suspension (made of milk powder) together with the auxiliary electrode, and the distance is kept at 5~15mm. A DC electric field is applied between the two electrodes, and graphene and carbon nanotubes are electrophoretic deposited on the graphite paper electrode. At this time, by electrophoresis, milk powder is wrapped and coated on graphene and carbon nanotubes, and activated carbon-bonded graphite paper / carbon nanotubes-graphene flexible electrodes with a three-dimensional spatial conductive network structure are prepared by vacuum high-temperature carbonization treatment. Graphite paper / carbon nanotube-graphene prepared under different electric field strength, deposition time, milk powder concentration in the suspension, graphene and carbon nanotube composition ratio, carbonization temperature, and holding time were studied. Conductivity tester, specific surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com