Method for preparing titanium/hydroxyapatite biological scaffold through die-free direct-write molding technology

A technology of hydroxyapatite and direct writing molding, applied in tissue regeneration, medical science, prosthesis, etc., can solve the problems of high technical requirements, low compressive strength, and harsh conditions for biological scaffolds, and achieve adjustable compression resistance Strength, improved mechanical properties, adjustable composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

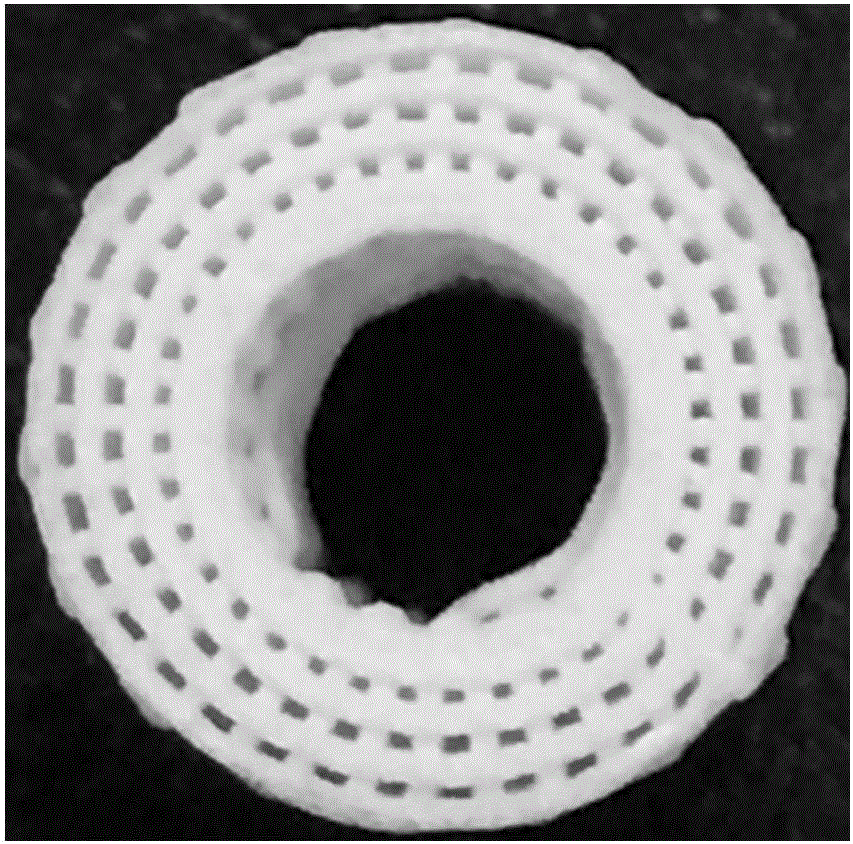

Image

Examples

Embodiment Construction

[0013] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0014] An embodiment of the present invention provides a method for preparing a titanium / hydroxyapatite bioscaffold by a moldless direct writing technique, comprising the following steps:

[0015] S01. Dispersing the mixed powder of hydroxyapatite powder and metal titanium powder in the medium to make a titanium / hydroxyapatite ceramic slurry with a solid phase content of 50-80wt%;

[0016] S02. Pre-design the three-dimensional structural diagram through CAD software, and convert it into a code language recognizable by the computer, put the titanium / hydroxyapatite ceramic slurry into the ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com