A kind of preparation method of visible light active g-c3n4/zn3(vo4)2 composite photocatalyst

A technology of g-c3n4 and VO4, which is applied in the field of preparation of g-C3N4/Zn32 composite photocatalyst, achieves the effect of short process, easy control of operation and high photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 0.1 g of g-C 3 N 4 And 0.0226 g of Zn 3 (OH) 2 V 2 O 7 ·2H 2 O, then add 50 mL of deionized water together and stir for 0.5 h. Rotary evaporate the solution, dry under vacuum at 30°C, and finally calcinate at 300°C for 2.0 h, heating rate 3°C·min -1 , Get g-C 3 N 4 / Zn 3 (VO 4 ) 2 Sample, which contains Zn 3 (VO 4 ) 2 The mass ratio is 20%. Zn 3 (OH) 2 V 2 O 7 ·2H 2 O is formed by intersecting nanosheets with a size of 80~200 nm to form a three-dimensional structure.

[0027] Visible light for 5.0 h, the photodegradation efficiency of rhodamine B dye is 60.13%.

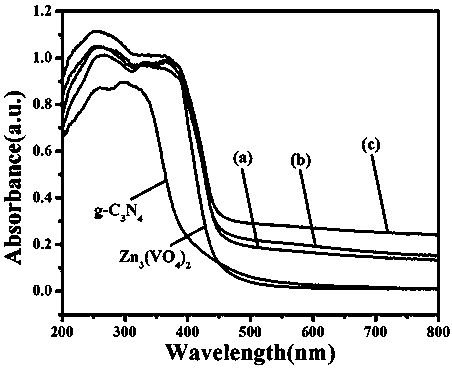

[0028] Attached image 3 Curve (a) is the solid ultraviolet graph of Example 1. As can be seen from the figure, and g-C 3 N 4 And Zn 3 (VO 4 ) 2 In contrast, the light absorption of the composite photocatalyst is red-shifted, and there is a strong absorption at 400-600 nm, indicating that the composite photocatalyst has a visible light effect.

Embodiment 2

[0030] Weigh 1.0 g of g-C 3 N 4 And 0.0113 g Zn 3 (OH) 2 V 2 O 7 ·2H 2 O, of which Zn 3 (OH) 2 V 2 O 7 ·2H 2 O is formed by intersecting nanosheets with a size of 80~200 nm to form a three-dimensional structure. Add 100 mL of deionized water and stir for 3.5 hours. The solution is rotary evaporated, dried at 40℃, and finally calcined at 350℃ for 2.5 hours. The heating rate is 4 ℃·min -1 , Get g-C 3 N 4 / Zn 3 (VO 4 ) 2 Sample, which contains Zn 3 (VO 4 ) 2 The mass ratio is 1%.

[0031] Visible light for 5.0 h, the photodegradation efficiency of rhodamine B dye is 65.47%.

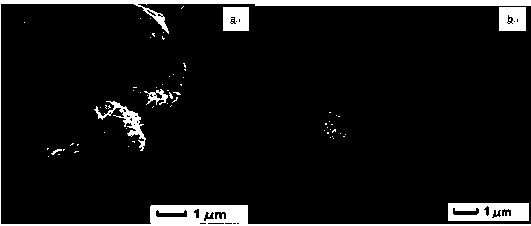

[0032] Attached figure 1 (A) is the SEM image of Example 2.

Embodiment 3

[0034] Weigh 5.0 g of g-C 3 N 4 And 0.1691 gZn 3 (OH) 2 V 2 O 7 ·2H 2 O, of which Zn 3 (OH) 2 V 2 O 7 ·2H 2 O is formed by intersecting nanosheets with a size of 80~200 nm to form a three-dimensional structure. Add 150 mL of deionized water and stir for 6.0 h. The solution is rotary evaporated, dried at 50 ℃, and finally calcined at 350 ℃ for 2.5 h. The heating rate is 5 ℃·min -1 , Get g-C 3 N 4 / Zn 3 (VO 4 ) 2 Sample, which contains Zn 3 (VO 4 ) 2 The mass ratio is 3%.

[0035] With visible light for 5.0 h, the photodegradation efficiency of rhodamine B dye is 76.27%.

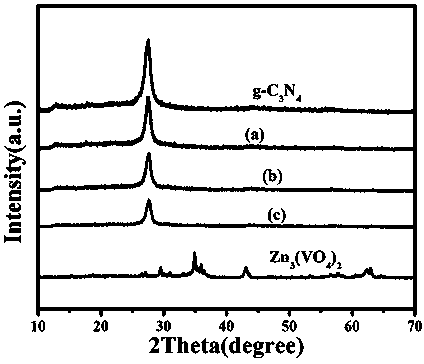

[0036] Attached figure 2 Curve (a) is the XRD pattern of Example 3. It can be seen from the figure that the composite photocatalyst g-C 3 N 4 / Zn 3 (VO 4 ) 2 G-C appears in the diffraction peaks 3 N 4 And Zn 3 (VO 4 ) 2 Characteristic peaks, indicating that the two are well combined together, because Zn 3 (VO 4 ) 2 The content is small, so the peak shape is not obvious.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com