Method for preparing hollow nickel silicate microspheres by using silicon dioxide as template

A technology of silicon dioxide and nickel silicate, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., to achieve the effect of being suitable for mass production, convenient and easy temperature control, and overcoming the difficulty of temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

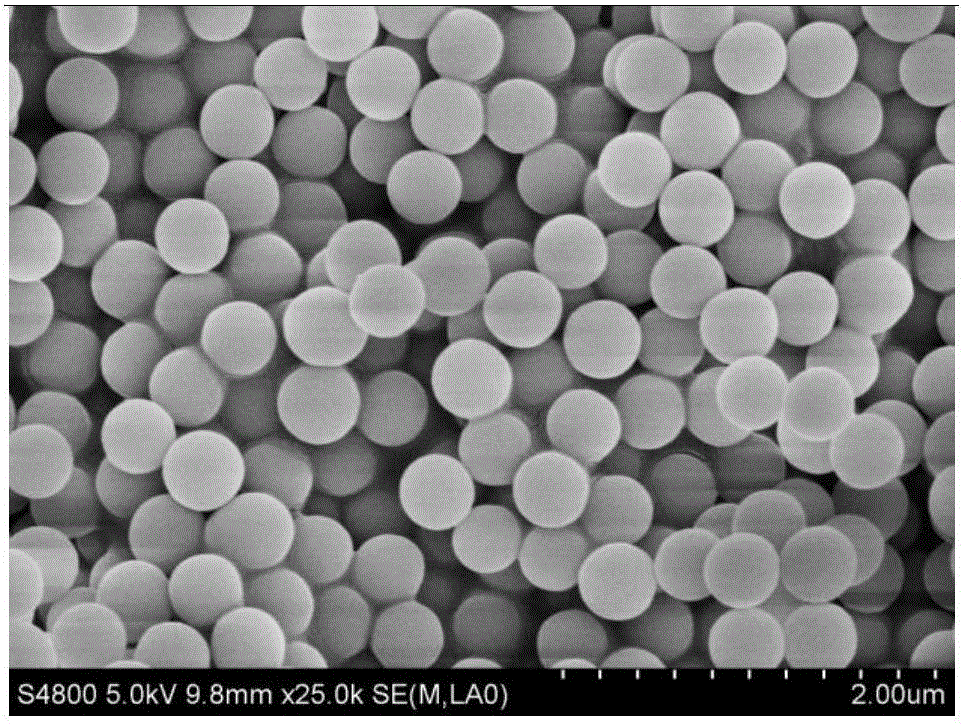

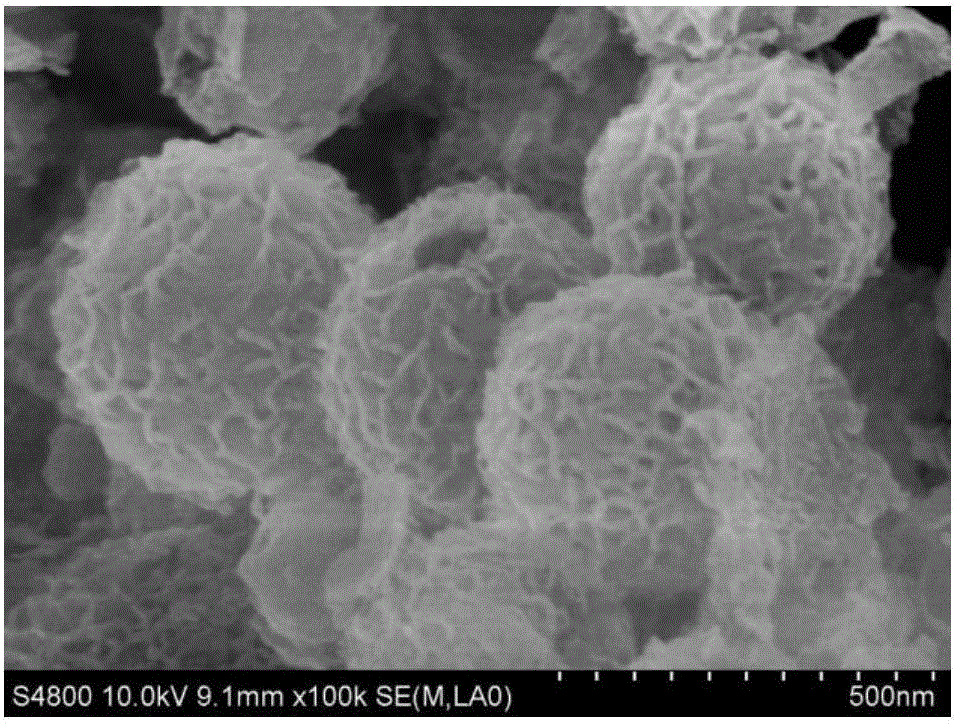

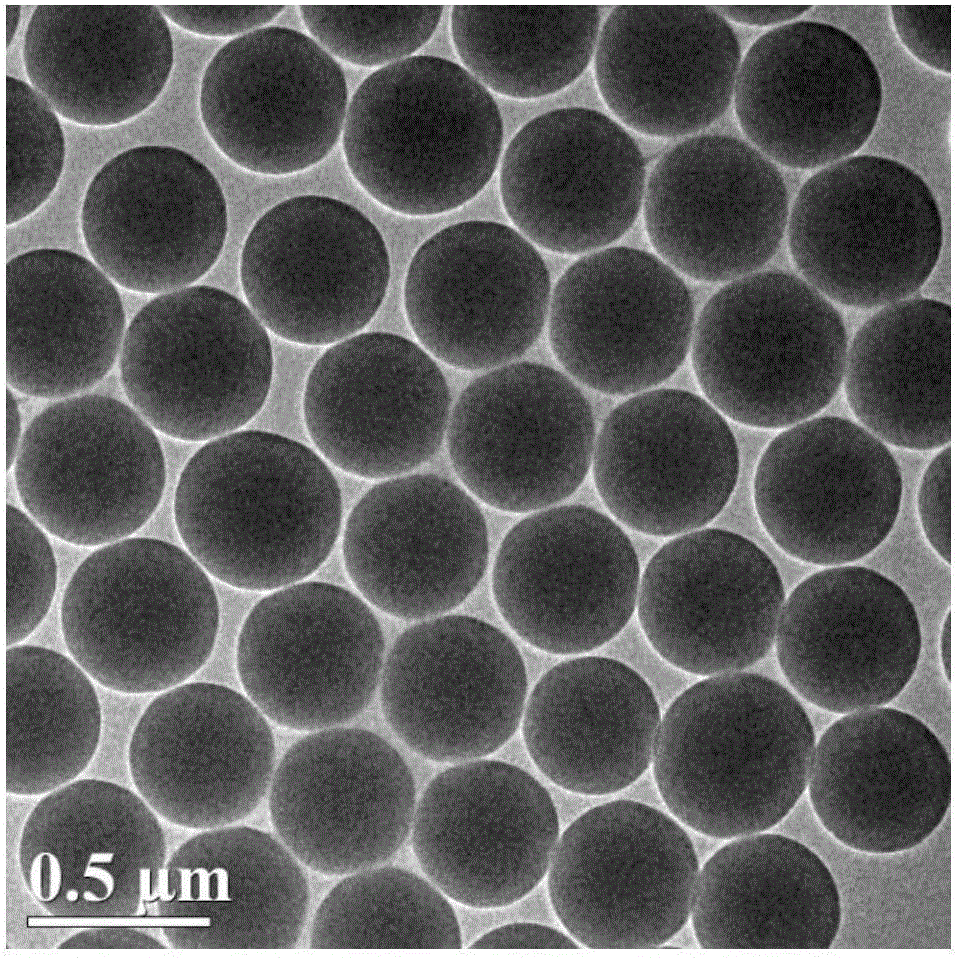

[0031] Disperse 0.2g of nano-silica in 40mL of deionized water and ultrasonically disperse for 1 hour to make it uniformly dispersed and form a white emulsion. Then, 1 g of urea and 0.18 g of nickel nitrate were added to the homogeneously dispersed nano-silica solution, and the stirring and dispersion was continued for 30 minutes to obtain a green emulsion. Subsequently, the green emulsion was transferred to a three-necked flask, and kept condensing and refluxing for 12 hours at a reaction temperature of 100°C. The product was filtered, washed, and freeze-dried to obtain nickel silicate / silicon dioxide microspheres. The dried nickel silicate / silicon dioxide microspheres were treated with 50 mL of prepared 1 mol / L sodium hydroxide solution for 16 h. Subsequently, the product was washed, suction filtered, and vacuum freeze-dried to obtain a light green solid powder, which was the desired hollow nickel silicate microspheres. The morphology and structure of the obtained product ...

Embodiment 2

[0033] Put 2g as figure 1 and image 3 The nano silicon dioxide shown is dispersed in 400mL of deionized water and ultrasonically dispersed for 1 hour to make it uniformly dispersed and form a white emulsion. Then, 10 g of urea and 1.8 g of nickel nitrate were added to the homogeneously dispersed nano-silica solution, and the stirring and dispersion was continued for 30 minutes to obtain a green emulsion. Subsequently, the green emulsion was transferred to a three-necked flask, and kept condensing and refluxing for 24 hours at a reaction temperature of 95°C. The product was filtered, washed and dried in vacuum to obtain nickel silicate / silicon dioxide microspheres. The dried nickel silicate / silicon dioxide microspheres were treated with 500 mL of a prepared 1.5 mol / L sodium hydroxide solution for 16 hours. Subsequently, the product was washed, suction filtered, and vacuum freeze-dried to obtain a light green solid powder, which was the desired hollow nickel silicate microsp...

Embodiment 3

[0035] Disperse 0.2 g of silica nanospheres in 40 mL of deionized water and ultrasonically disperse for 1 h to make them uniformly dispersed and form a white emulsion. Then, 1 g of urea and 0.2 g of nickel acetate were added to the homogeneously dispersed nano-silica solution, and the stirring and dispersion was continued for 30 minutes to obtain a green emulsion. Subsequently, the green emulsion was transferred to a three-necked flask, and kept condensing and refluxing for 24 hours at a reaction temperature of 85°C. The product was filtered, washed and dried in vacuum to obtain nickel silicate / silicon dioxide microspheres. The dried nickel silicate / silicon dioxide microspheres were treated with 50 mL of prepared 1.2 mol / L potassium hydroxide solution for 14 h. Subsequently, the product was washed, suction filtered, and vacuum freeze-dried to obtain a light green solid powder, which was the desired hollow nickel silicate microspheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com