A kind of ecological permeable concrete and preparation method thereof

A permeable concrete and ecological technology, applied in the field of new ecological permeable concrete and its preparation, can solve the problems of high energy consumption in production, achieve the effects of reducing production costs, being suitable for large-scale use, and reducing environmental pollution and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

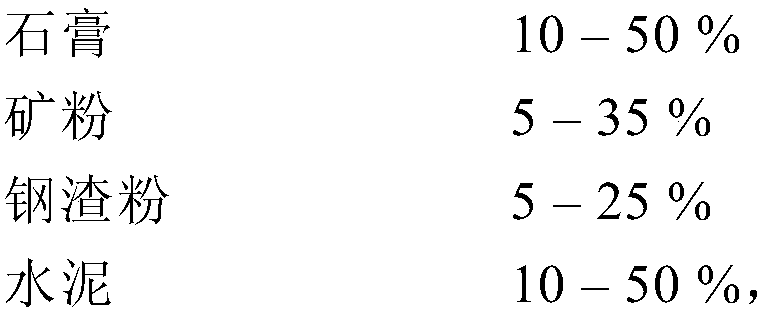

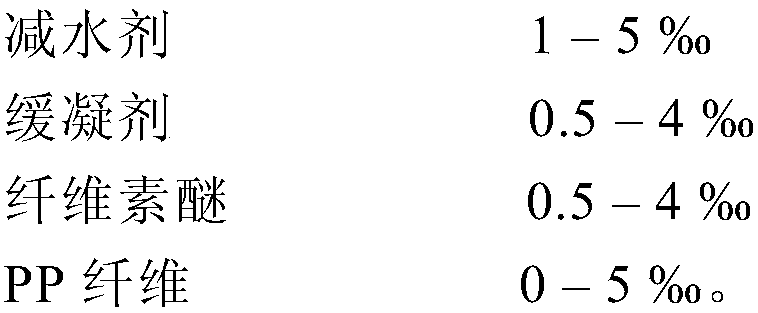

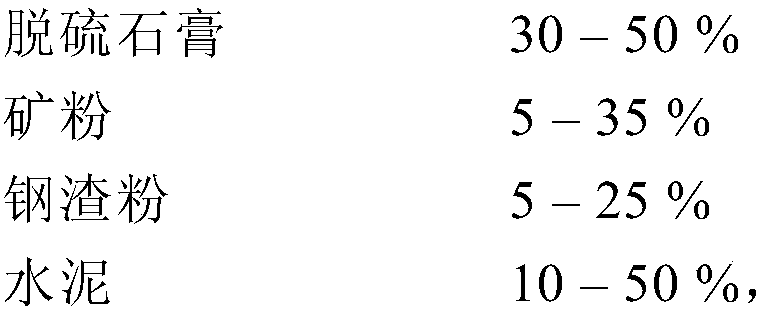

Method used

Image

Examples

Embodiment 1

[0064] Three components of permeable concrete: modified gypsum cementitious material 20%, aggregate 75%, water 5%.

[0065] The main ingredients of the modified gypsum cementitious material are: 40% gypsum, 30% slag powder, 20% steel slag powder, and 10% cement, wherein the gypsum is a single-component desulfurized gypsum;

[0066] Construction admixtures and their percentages to the mass of main materials are: retarder 2‰, water reducer 2‰, cellulose 0.5‰;

[0067] The aggregate is steel slag, the particle size of coarse aggregate is 3-5mm, and the dosage is 100%;

[0068] The performance is as follows:

[0069]

Embodiment 2

[0071] Three components of permeable concrete: modified gypsum cementitious material 10%, aggregate 88%, water 2%.

[0072] The main ingredients of the modified gypsum cementitious material are: 40% gypsum, 30% slag powder, 20% steel slag powder, and 10% cement, wherein the gypsum is mixed with desulfurized gypsum and phosphogypsum at a mass ratio of 1:1;

[0073] The building admixture and its percentage per thousand to the mass of the main material are: retarder 2‰, water reducing agent 3‰, cellulose 0.5‰, PP fiber 1‰;

[0074] The aggregate is steel slag, the particle size of fine aggregate is 1-3mm, the dosage is 25%, the particle size of coarse aggregate is 3-5mm, and the dosage is 75%;

[0075] The performance is as follows:

[0076]

Embodiment 3

[0078] Three components of permeable concrete: modified gypsum cementitious material 20%, aggregate 75%, water 5%.

[0079] The main ingredients of the modified gypsum cementitious material are: 30% gypsum, 35% slag powder, 25% steel slag powder, and 10% cement. The gypsum is desulfurized gypsum, phosphogypsum and fluorogypsum in a mass ratio of 1:1:1 mix;

[0080] Construction admixtures and their percentages per thousand to the mass of main materials are: retarder 2‰, water reducing agent 2‰, cellulose 1‰, PP fiber 2‰;

[0081] The aggregate is steel slag, the particle size of fine aggregate is 1-3mm, the dosage is 10%, the particle size of coarse aggregate is 3-5mm, and the dosage is 90%;

[0082] The performance is as follows:

[0083]

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com