A kind of preparation method and application of fusel oil odor remover

A technology of remover and fusel oil, applied in the preparation of organic compounds, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve the problems of unsuitable desulfurization and deodorization, single function, etc., and achieve obvious deodorization effect and simple process , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

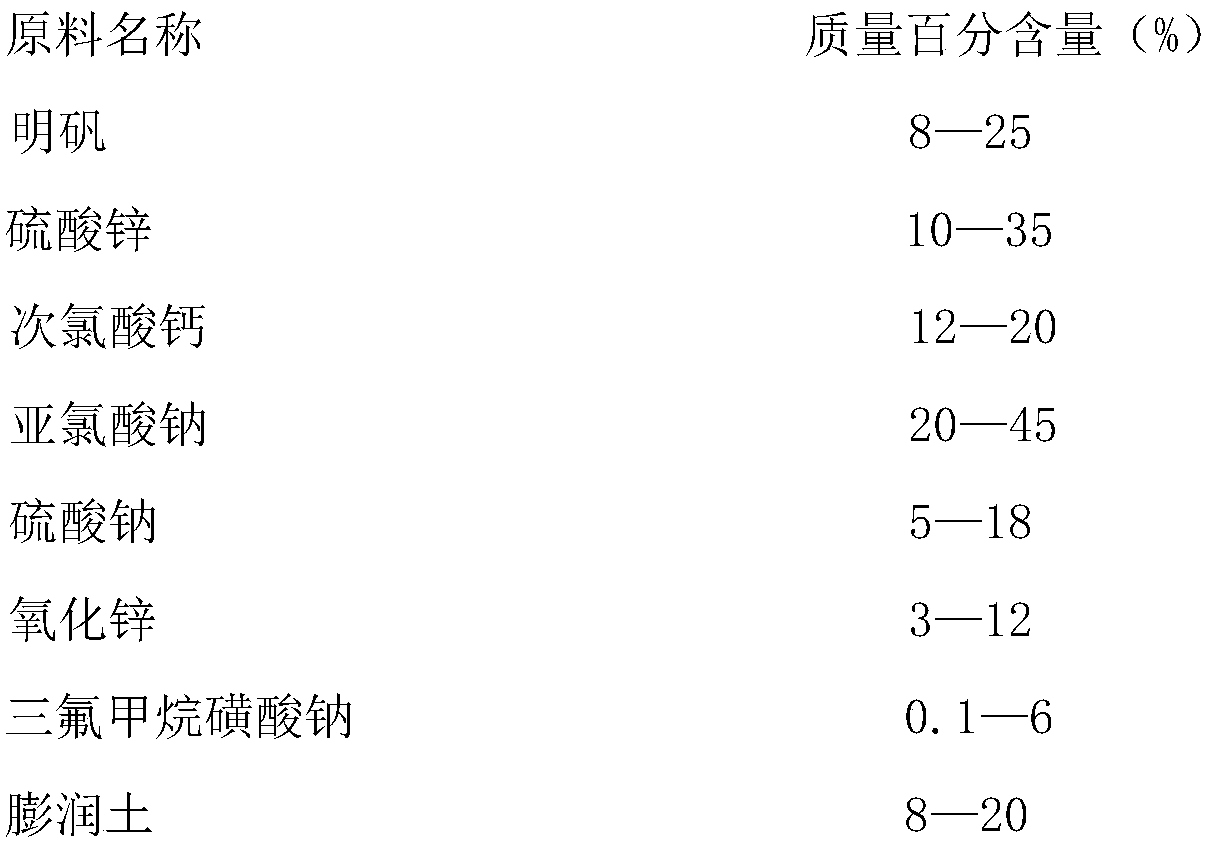

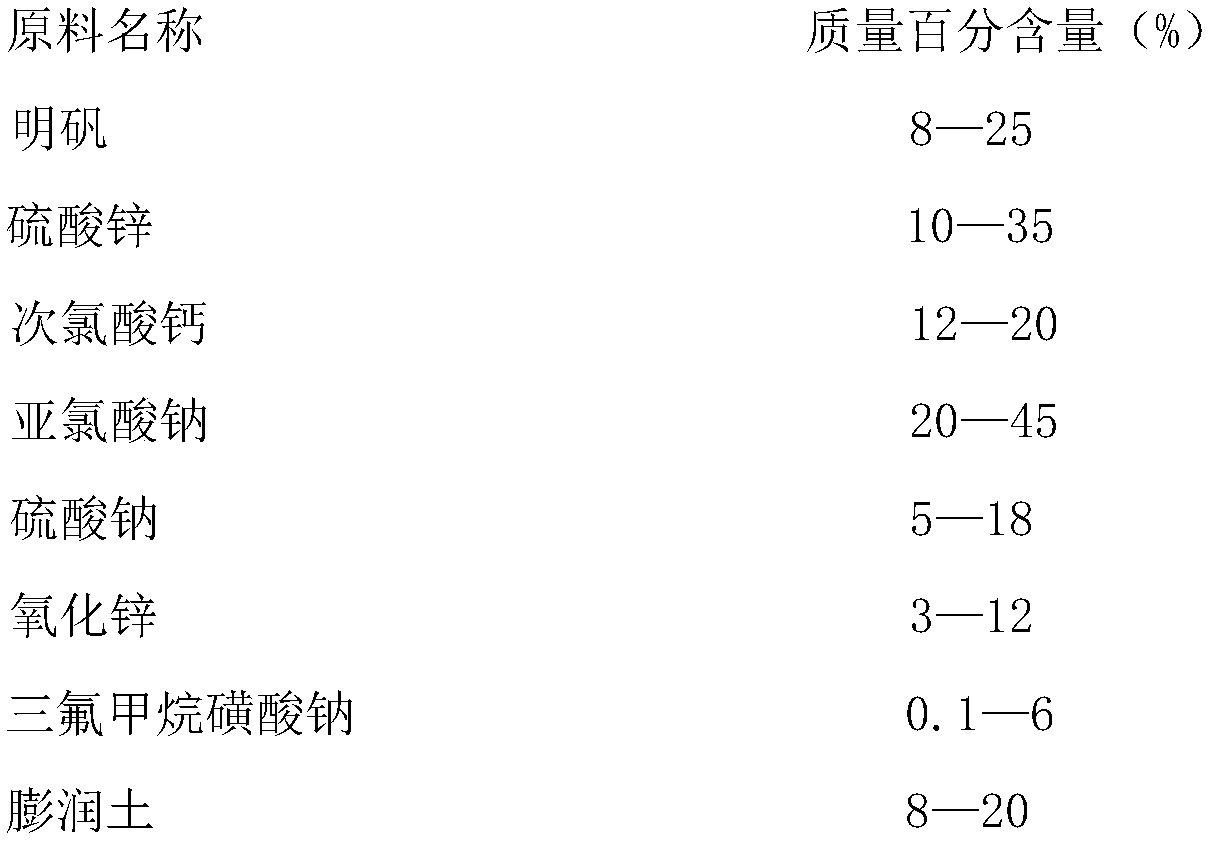

[0016]

[0017] The sum of the above components equals 100.

[0018] Put bentonite, alum, zinc sulfate, sodium sulfate, and zinc oxide into the mixing container in the order, mix well, add calcium hypochlorite, sodium chlorite and sodium trifluoromethanesulfonate, mix well and set aside.

[0019] Get fusel oil odor remover 1g, join in 1000ml fusel oil, fully stir, filter, can obtain odorless fusel oil.

Embodiment 2

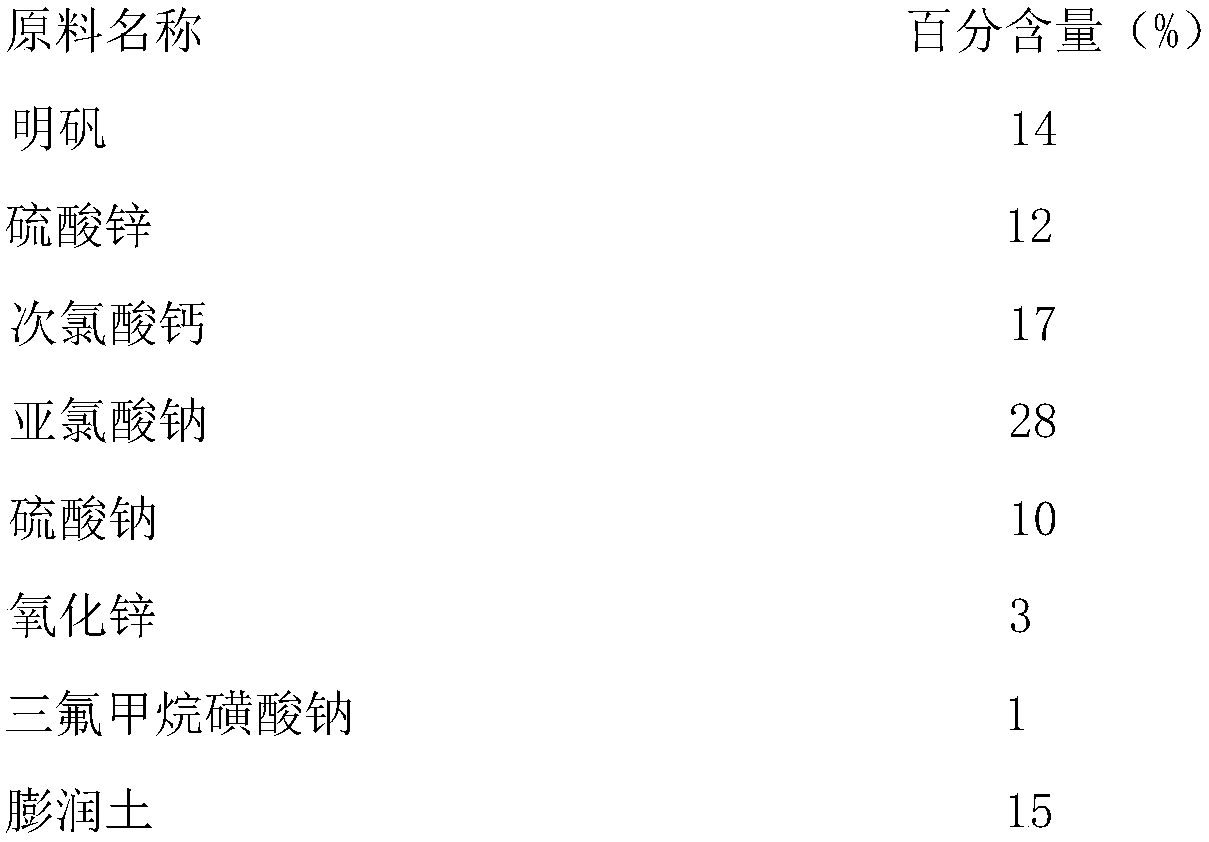

[0021]

[0022] The sum of the above components equals 100.

[0023] Put bentonite, alum, zinc sulfate, sodium sulfate, and zinc oxide into the mixing container in the order, mix well, add calcium hypochlorite, sodium chlorite and sodium trifluoromethanesulfonate, mix well and set aside.

[0024] Get fusel oil odor remover 2g, join in 2500ml fusel oil, fully stir, filter, can obtain odorless fusel oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com