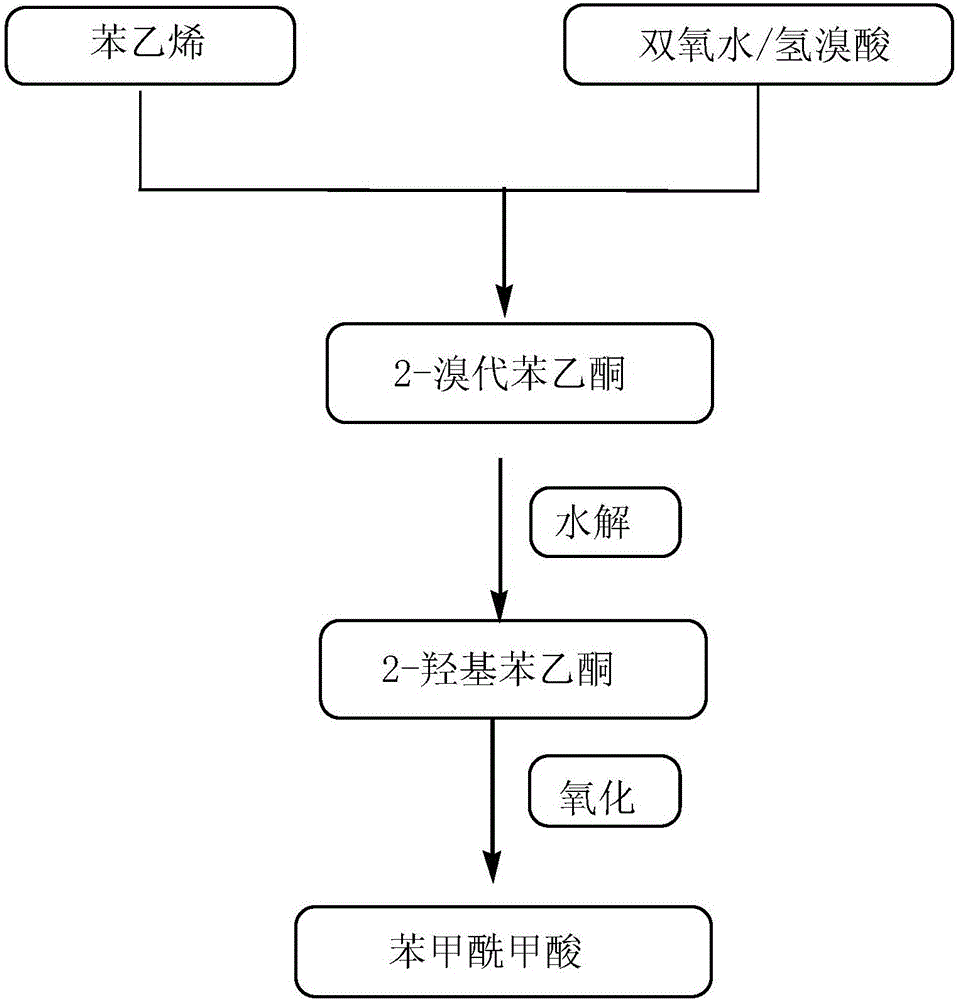

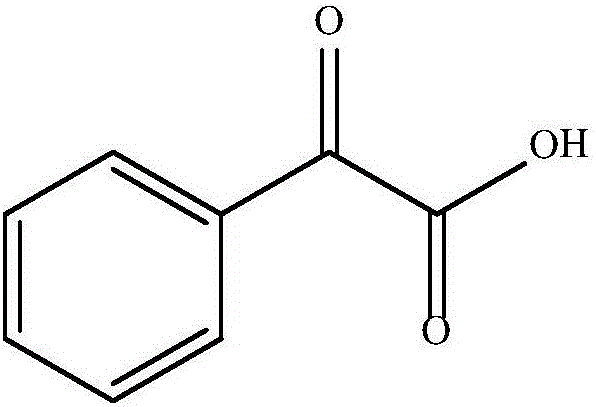

Clean method for synthesis of phenylglyoxylic acid

A benzoylformic acid, clean technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylates, etc., can solve the problem that the total yield of the target product is not high, the benzoylformic acid method is backward, unfavorable and sustainable Development and other issues to achieve the effect of reducing the generation of organic by-products, lowering the cost, and improving the cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Add 20mmol 48% hydrobromic acid at room temperature to a 500mL three-neck flask with 20mmol styrene and 100mL water, slowly add 200mmol 30% hydrogen peroxide dropwise, control the dropping time for 30min, stir at room temperature for 30min, heat up to 80°C, and react 10h. The organic and aqueous phases were separated on standing. The organic phase containing 2-bromoacetophenone was added to a reactor filled with 150 mL of water, hydrolyzed completely under the promotion of microwave, and the organic phase was separated from the water phase by standing. Place the organic phase containing 2-hydroxyacetophenone in a 500mL reactor, add 150g of water and 20mmol of 48% hydrobromic acid solution, and slowly add 16mmol of 30% hydrogen peroxide dropwise under stirring for 1h. After the addition, the temperature is slowly raised to React at 70°C for 6 hours, lower to room temperature and let stand to separate the organic phase from the water phase. The separated organic phase is...

Embodiment 2

[0036]Add 21mmol 48% hydrobromic acid at room temperature to a 500mL three-neck flask with 20mmol styrene and 100mL water, slowly add 200mmol 30% hydrogen peroxide dropwise, control the dropping time for 30min, stir at room temperature for 30min, heat up to 80°C, and react 10h. The organic and aqueous phases were separated on standing. Add the organic phase containing 2-bromoacetophenone into a reactor filled with 150 mL of water, complete hydrolysis under heating, and let stand to separate the organic phase and the water phase. Place the organic phase containing 2-hydroxyacetophenone in a 500mL reactor, add 150g of water and 20mmol of 48% hydrobromic acid solution, and slowly add 16mmol of 30% hydrogen peroxide dropwise under stirring for 1h. After the addition, the temperature is slowly raised to React at 90°C for 5 hours, lower to room temperature and let stand to separate the organic phase from the water phase. The separated organic phase is then distilled, refined and dr...

Embodiment 3

[0038] Add 20mmol 48% hydrobromic acid at room temperature to a 500mL three-necked flask with 20mmol styrene and 100mL water, slowly add 210mmol 30% hydrogen peroxide dropwise, control the dropping time for 60min, stir at room temperature for 30min, heat up to 80°C, and react 10h. The organic and aqueous phases were separated on standing. The organic phase containing 2-bromoacetophenone was added to a reactor filled with 150 mL of water, hydrolyzed completely under the promotion of microwave, and the organic phase was separated from the water phase by standing. Place the organic phase containing 2-hydroxyacetophenone in a 500mL reactor, add 150g of water and 20mmol of 48% hydrobromic acid solution, and slowly add 16mmol of 30% hydrogen peroxide dropwise under stirring for 1h. After the addition, the temperature is slowly raised to React at 90°C for 6 hours, lower to room temperature and let stand to separate the organic phase from the water phase. The separated organic phase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com