Graft-modified ultra-high molecular weight ultra-fine polyethylene and its solid-phase grafting method

A technology of ultra-high molecular weight and grafted polyethylene, which is applied in the field of grafted polymers and its preparation, can solve problems such as increased production costs, complex reaction processes, and difficulty in achieving large-scale low-cost production, and achieves low cost and simple process , the effect of easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

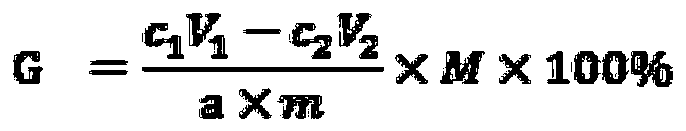

Image

Examples

preparation example Construction

[0043] The preparation of the above-mentioned powder can adopt the method disclosed in the invention patent application titled "ultra-high molecular weight ultra-fine polyethylene powder and its preparation method" submitted by the applicant on the same day of the application, and the full text of which is incorporated in this application as a reference .

[0044] Specifically, the above-mentioned powder is prepared by the following method: a preparation method of ultra-high molecular weight and ultra-fine particle diameter polyethylene powder, which includes the following steps:

[0045] Under the action of a catalyst, ethylene undergoes a polymerization reaction; wherein, the temperature of the polymerization reaction is -20 to 100°C; in ethylene, the content of carbon monoxide is less than 5ppm, the content of carbon dioxide is less than 15ppm, and the content of conjugated dienes is less than 10ppm;

[0046] The catalyst is prepared by a method comprising the following ste...

preparation example 1

[0105] Preparation Example 1 The preparation of ultra-high molecular weight ultra-fine particle diameter polyethylene powder

[0106] In the reactor fully replaced by high-purity nitrogen, add 4.94g of anhydrous magnesium chloride, 18.9g of isooctyl alcohol, and 30ml of decane in sequence, raise the temperature to 130°C under stirring, and maintain it for 2 hours, then add 2.65g of tetrabutyl titanate The ester and 2.05g of diisobutyl phthalate were reacted at 130°C for 1 hour, and finally cooled to room temperature to form a homogeneous transparent solution, namely mixture I.

[0107] Add 200ml of titanium tetrachloride to the reaction kettle, stir and preheat to 0°C, add the mixture I dropwise to the titanium tetrachloride in about 2 hours. After the dropwise addition was completed, the temperature was raised to 110° C. within 2 hours. 1.23 g of internal electron donor diisobutyl phthalate was added. After reacting at this temperature for 2 hours, remove the reaction liqui...

Embodiment 1

[0112] Preparation of PE-g-MAH: In the reactor fully replaced by high-purity nitrogen, add 40g of polyethylene particles with an average particle diameter of 85 microns prepared in Preparation Example 1 (the standard deviation is 8.21 microns, and the viscosity-average molecular weight is 1.3× 10 6 , molecular weight distribution is 9.2), add 2.0g benzoyl peroxide, add 2.8g maleic anhydride (MAH), add 4mL tetrahydrofuran and 5mL xylene; then turn on the mechanical stirring, stir rapidly for 3 hours; finally put the reactor into In an oil bath at 100°C, react for 2 hours to obtain the crude grafted product.

[0113]Refining of PE-g-MAH: Weigh about 4g of crude graft, add 200mL of xylene into a 500mL distillation flask, heat and dissolve, reflux for 4h, add acetone (about 200mL) after cooling, shake well, let it settle and filter , and then washed once with acetone, put the filtrate in a 50°C oven to dry for 12 hours, and cool to obtain a refined graft.

[0114] Infrared chara...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com