Graft modification ultrafine polyolefin and solid-phase grafting method thereof

A technology of solid-phase grafting and polyolefin, applied in the field of grafted polymers and its preparation, can solve problems such as increased production costs, complex reaction processes, and difficulty in achieving large-scale low-cost production, and achieves low cost, simple process, The effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Preparation of PP-g-MAH: In a reactor fully replaced by high-purity nitrogen, add 40g of 5 Add 2.0g of benzoyl peroxide, 2.8g of maleic anhydride (MAH), 4mL of tetrahydrofuran and 5mL of xylene; then turn on the mechanical stirring and stir rapidly for 4 hours; finally put the reactor at 120°C In an oil bath, react for 2 hours to obtain the product.

[0043] Refining of PP-g-MAH: Weigh about 4g of crude graft, add 200mL of xylene into a 500mL distillation flask, heat and dissolve, reflux for 4h, add acetone (about 200mL) after cooling, shake well, let it settle and filter , and then washed once with acetone, put the filtrate in a 50°C oven to dry for 12 hours, and cool to obtain a refined graft.

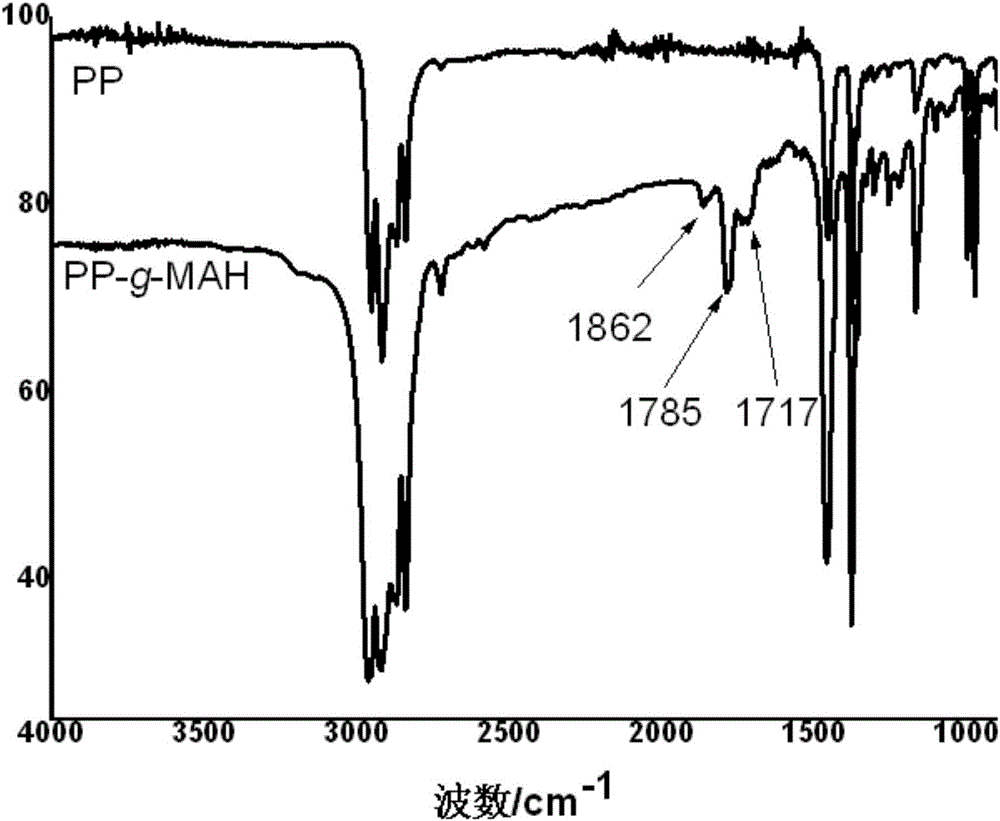

[0044] Infrared characterization of PP-g-MAH: measure the infrared spectrum of the refined graft according to the aforementioned method, the results are shown in figure 1 , where the upper part is the polypropylene raw material; the lower part is the grafted polymer. 1862cm...

Embodiment 2

[0051] Preparation of PP-g-MAH: In a reactor fully replaced by high-purity nitrogen, add 40g of 4 Add 2.0g of azobisisobutyronitrile, 2.8g of maleic anhydride (MAH), 3mL of tetrahydrofuran and 6mL of xylene; then turn on mechanical stirring and stir rapidly for 4 hours; finally put the reactor into 120 In an oil bath at ℃, react for 2 hours to obtain the product. The effective grafting rate of maleic anhydride of the grafted polymer was measured to be 3.25%, and the water contact angle of the grafted polymer was 74°.

Embodiment 3

[0053] Preparation of PP-g-AA: In a reactor fully replaced by high-purity nitrogen, add 40g of 6 Add 2.0g of benzoyl peroxide, 2.8g of acrylic acid (AA), and 5mL of xylene; then turn on the mechanical stirring and stir rapidly for 4 hours; finally add the reactor and put it in an oil bath at 120°C, After 2 hours of reaction, the product was obtained. It is measured that the effective grafting rate of acrylic acid of the grafted polymer is 3.14%, and the water contact angle of the grafted polymer is 70°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com