Epoxy-modified polysiloxane paint and preparation method thereof

An epoxy modification and polysiloxane technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of high VOC content, poor alkali resistance, low hardness, etc., achieve low VOC content, good corrosion resistance, prolonged The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation of embodiment 1 epoxy-modified polysiloxane resin

[0026] Mix 100kg of Dow Corning DC-3074 and 20kg of tetraethyl orthosilicate to make a polysiloxane intermediate; add 15kg of hydrogenated epoxy resin (ZD6040E) and 15kg of TPGDA to the above polysiloxane intermediate. Under protection, react at 80°C for 2 hours to synthesize epoxy-modified polysiloxane resin.

Embodiment 2

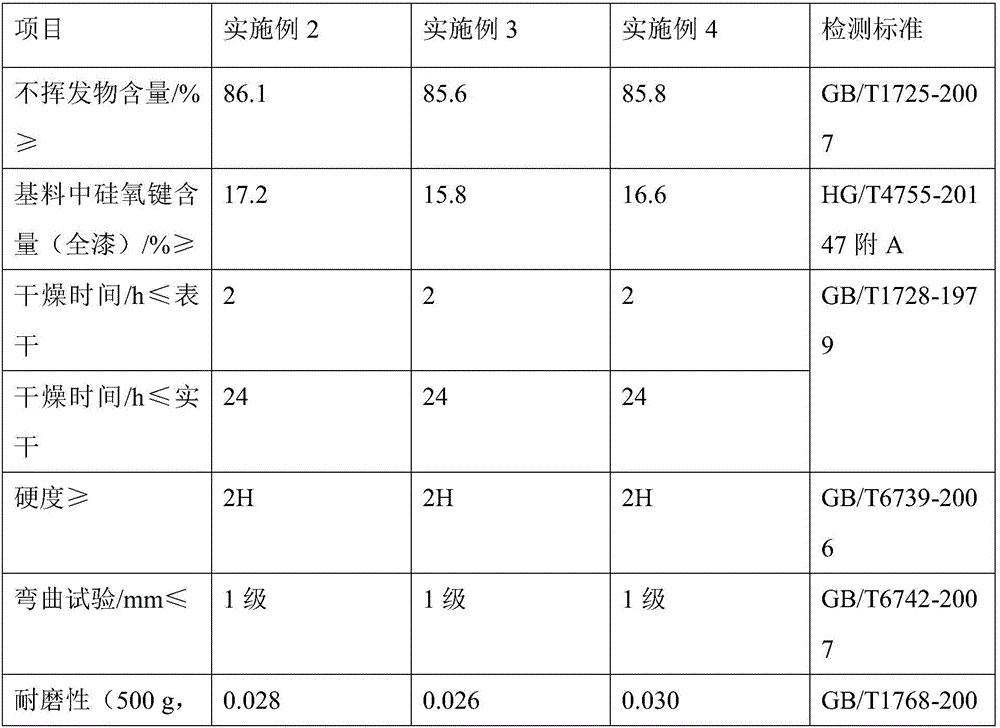

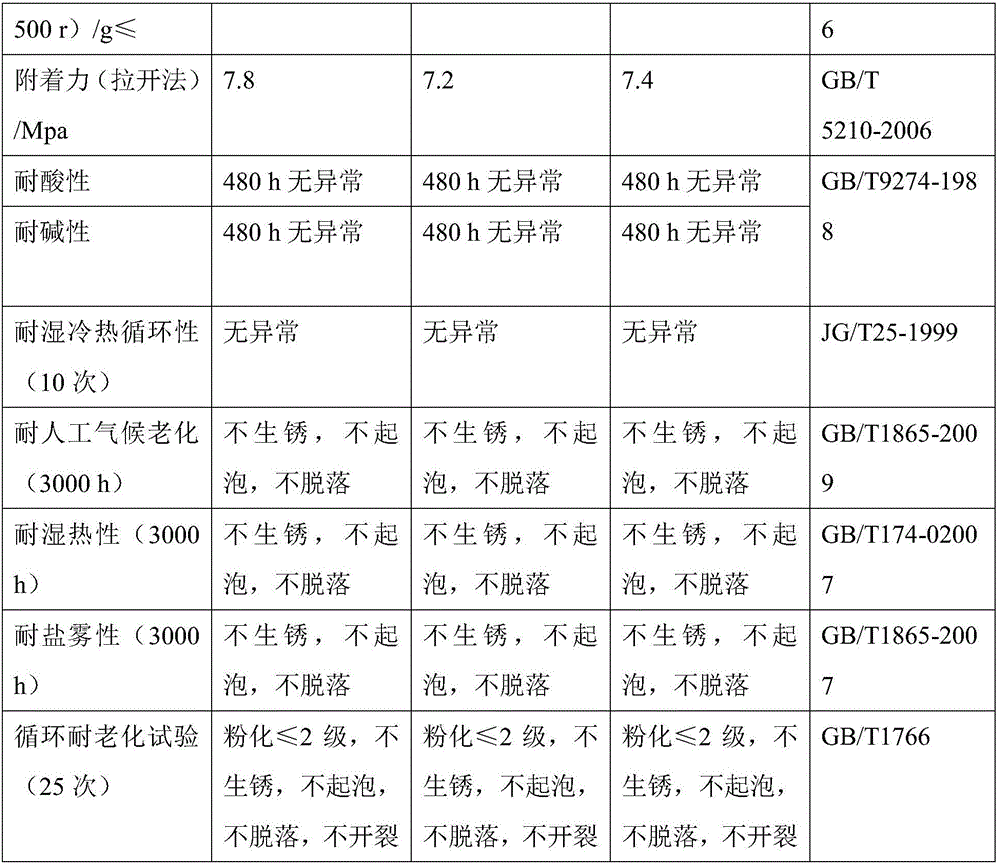

[0027] The preparation of embodiment 2 epoxy-modified polysiloxane coatings

[0028] First weigh 65kg of the prepared epoxy-modified polysiloxane resin (prepared according to the method of Example 1) and add it to the grinding tank, and then add 0.3kg of wetting and dispersing agent BYK110, 0.5kg of BYK-A530 defoamer, 2.2kg of rheology additive 201P (purchased from Deqian), 30kg of titanium dioxide and 2kg of fumed silica, stirred at 800rpm / min for 30min, then ground by a sand mill until the particle size is less than or equal to 20μm, and then filtered for 15min Component A: Dilute the amine curing agent ELNT-7010 to 60w / v% with xylene, stir at a low speed of 200rpm / min for 30min to obtain component B.

[0029] Components A and B are used in combination according to the weight ratio of 4:1, and the substrate to be coated can be coated by spraying, brushing, and rolling to form a uniform coating on the substrate .

Embodiment 3

[0031] First weigh 68kg of the prepared epoxy-modified polysiloxane resin (prepared according to the method of Example 1) and add it to the grinding tank, and add 0.3kg of wetting and dispersing agent BYK110 and 0.5kg of BYK successively under low-speed stirring -A530 defoamer, 2.2kg of rheology additive 201P (purchased from Deqian), 28kg of titanium dioxide and 1kg of fumed silica, stirred at 800rpm / min for 30min and then ground by a sand mill until the particle size is less than or equal to 20μm, Stand still for 15 minutes and filter to obtain component A; dilute acryloyloxypropyltrimethoxysilane with xylene to 60w / v%, stir at a low speed of 200rpm / min for 30min to obtain component B.

[0032] The weight ratio of component A and component B is 4:1, and the substrate to be coated can be coated by spraying, brushing and rolling to form a uniform coating on the substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com