Black phosphorus quantum dot and preparation method thereof

A technology of quantum dots and black phosphorus, applied in the field of black phosphorus quantum dots and its preparation, can solve the problems of low yield of flake black phosphorus, less amount of black phosphorus flakes, large material size, etc. Good dispersion, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A preparation method of black phosphorus quantum dots, comprising the steps of:

[0054] (1) Weigh 10 mg of bulk black phosphorus in a nitrogen-filled glove box, grind it and disperse it in 10 mL of N-methylpyrrolidone, seal it, and obtain the first dispersion of 1 mg / mL;

[0055] (2) Take 2 mL of the above-mentioned first dispersion, add 18 mL of N-methylpyrrolidone to dilute, then add 200 mg of sodium hydroxide, and stir evenly to obtain the second dispersion;

[0056] (3) Add the above-mentioned second dispersion liquid into a polytetrafluoroethylene high-pressure reactor, heat and react at a temperature of 140°C for 18 hours, and after the resulting reaction liquid is cooled to room temperature, centrifuge at a speed of 7000 rpm for 20 minutes , collecting the supernatant to obtain black phosphorus quantum dots dispersed in N-methylpyrrolidone.

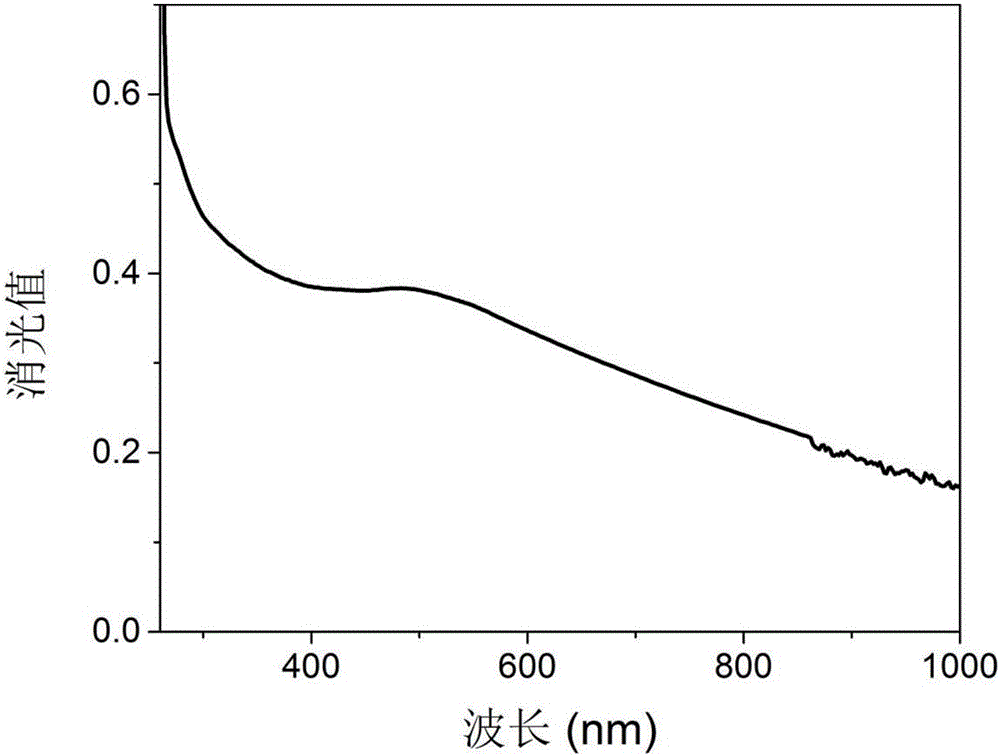

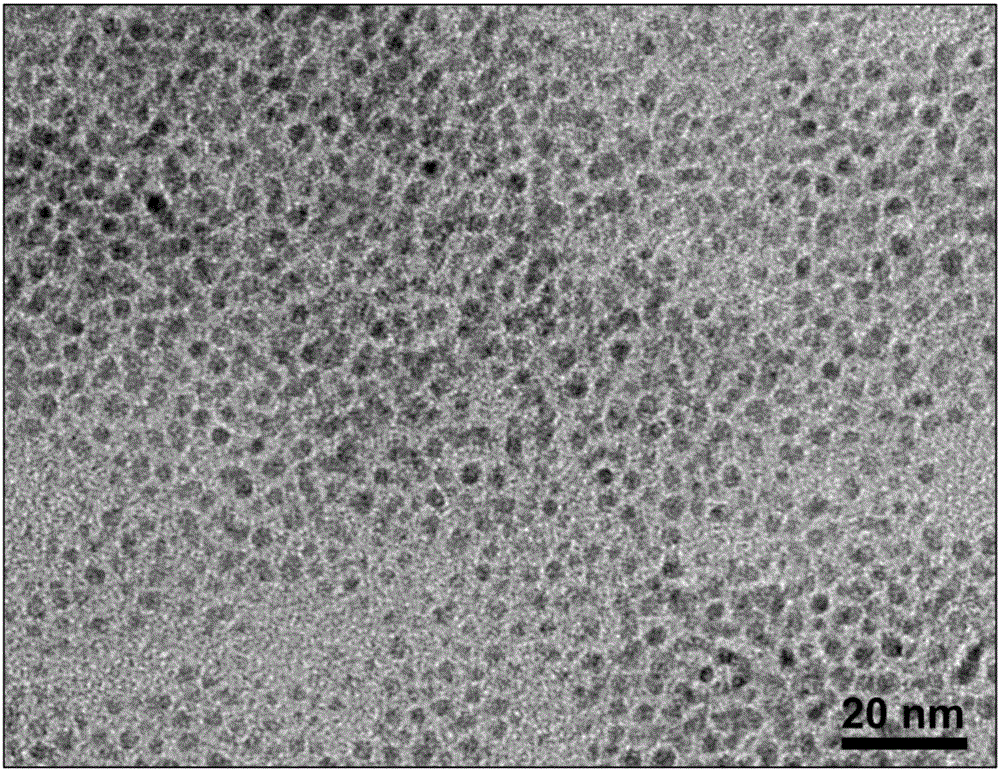

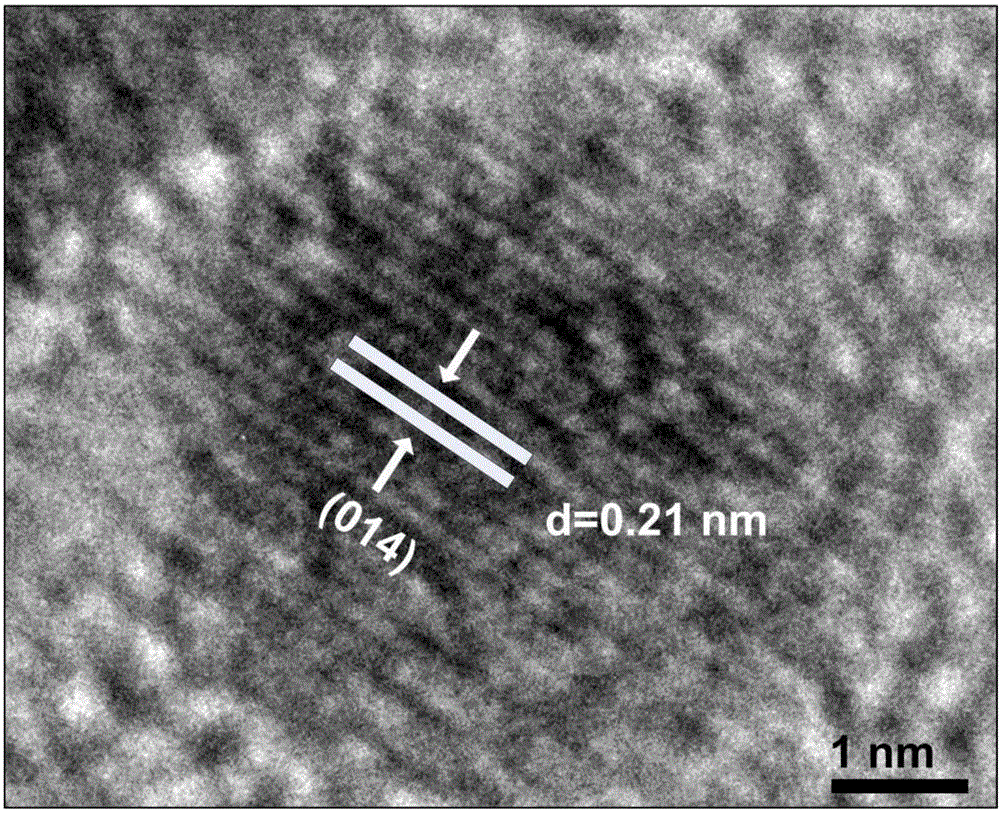

[0057] The black phosphorus quantum dots obtained in Example 1 are relatively stable and can be stored at room temperatu...

Embodiment 2

[0060] A preparation method of black phosphorus quantum dots, comprising the steps of:

[0061] Weigh 30 mg of bulk black phosphorus in a nitrogen-filled glove box, grind it and disperse it in 25 mL of N-methylpyrrolidone, seal it, and obtain the first dispersion of 1.2 mg / mL;

[0062] Take 4mL of the first dispersion above, add 36mL of N-methylpyrrolidone, and add 400mg of sodium hydroxide, stir evenly to obtain the second dispersion;

[0063] Add the above-mentioned second dispersion liquid into the autoclave, and heat the reaction at 120°C for 14 hours. After the heating is completed and the system is cooled to room temperature, centrifuge the obtained reaction liquid at a speed of 9000 rpm for 10 minutes, collect supernatant; then the collected supernatant was subjected to high-speed centrifugation for 20min at a speed of 12000rpm to collect the solid product or disperse the solid product in absolute ethanol to obtain black phosphorus dispersed in absolute ethanol with a s...

Embodiment 3

[0065] A preparation method of black phosphorus quantum dots, comprising the steps of:

[0066] Weigh 12 mg of bulk black phosphorus in a nitrogen-filled glove box, grind it and disperse it into 20 mL of N-methylpyrrolidone, seal it, and obtain the first dispersion of 0.6 mg / mL;

[0067] Take 3mL of the above-mentioned first dispersion, add 27mL of dimethylformamide, and add 300mg of sodium hydroxide, stir evenly to obtain the second dispersion;

[0068] Add the above-mentioned second dispersion liquid into a high-pressure reaction kettle, heat the reaction at 130°C for 10 hours, after the heating is completed, and the system is cooled to room temperature, centrifuge the obtained reaction liquid at a speed of 6000 rpm for 30 minutes, collect supernatant to obtain black phosphorus quantum dots dispersed in N-methylpyrrolidone.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Absorption peak | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com