Coating method of super-hard antifriction abrasion-resistance composite film layer on surface of titanium alloy and titanium alloy material

A composite film layer and titanium alloy technology, applied in metal material coating process, coating, sputtering plating, etc., can solve problems such as poor wear resistance, achieve improved wear resistance, excellent bearing capacity, and improved friction The effect of academic conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

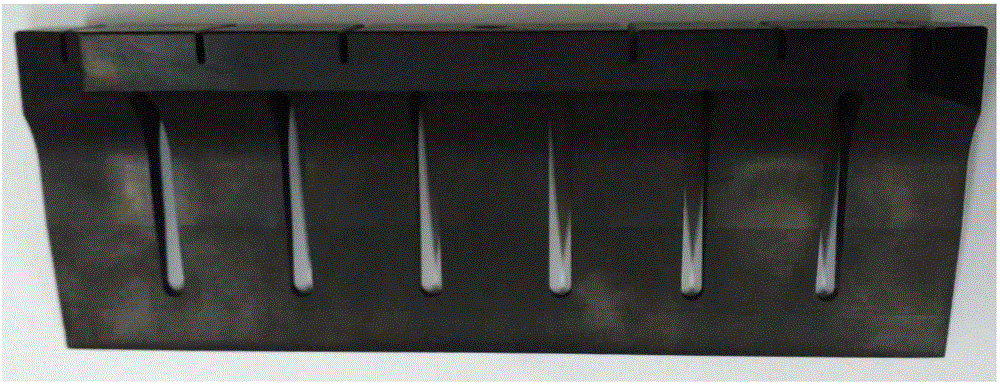

[0035] A TC4 titanium alloy ultrasonic cutting knife is selected as the substrate of the embodiment.

[0036] The specific preparation steps of superhard anti-friction and wear-resistant coating on the surface are as follows:

[0037] (1) ultrasonically clean the ultrasonic cutting cutter in ethanol to remove surface processing oil stains, etc.;

[0038] (2) Clean the previous degreasing process in deionized water to remove the cleaning residue of the ultrasonic cutting cutter;

[0039] (3) Drying the ultrasonic cutting cutter in a vacuum oven;

[0040] (4) Install the ultrasonic cutting knife on the workpiece frame, and vacuum the sputtering chamber to 2.0×10 -4 Pa;

[0041](5) Introduce argon gas into the vacuum chamber, the flow rate of argon gas is 20sccm, the pressure of the vacuum chamber is adjusted to 0.5Pa, the ion source is turned on at 2.5kV, the ion beam current is 30mA, the working time is 30min, and the ultrasonic cutting knife is cleaned with cations ;

[0...

Embodiment 2

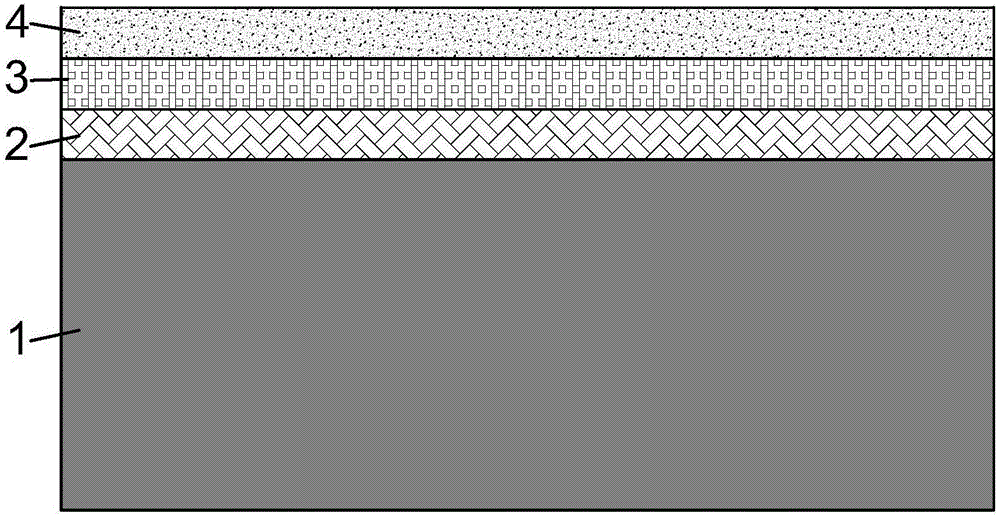

[0054] A coating method for a superhard friction-reducing and wear-resistant composite film layer on the surface of a titanium alloy, using high-purity argon (99.99%), high-purity nitrogen (99.99%), high-purity titanium (99.99%) targets, and high-purity graphite ( 99.99%) target, the titanium film (Ti), titanium carbonitride film (TiCN) and diamond-like film (DLC) were sequentially deposited on the surface of the titanium alloy by magnetron sputtering to establish a Ti / TiCN / DLC surface enhanced A composite film layer, wherein the titanium film is used as a metal bonding layer, the titanium carbonitride film is used as a bearing layer, and the diamond-like film is used as a friction-reducing and wear-resisting layer on the surface.

[0055] The titanium alloy in this embodiment is specifically Ti-6Al-4V.

[0056] The coating method of the superhard friction-reducing and wear-resisting composite film layer on the surface of the titanium alloy in this embodiment specifically incl...

Embodiment 3

[0071] A coating method for a superhard friction-reducing and wear-resistant composite film layer on the surface of a titanium alloy, using high-purity argon (99.99%), high-purity nitrogen (99.99%), high-purity titanium (99.99%) targets, and high-purity graphite ( 99.99%) target, the titanium film (Ti), titanium carbonitride film (TiCN) and diamond-like film (DLC) were sequentially deposited on the surface of the titanium alloy by magnetron sputtering to establish a Ti / TiCN / DLC surface enhanced A composite film layer, wherein the titanium film is used as a metal bonding layer, the titanium carbonitride film is used as a bearing layer, and the diamond-like film is used as a friction-reducing and wear-resisting layer on the surface.

[0072] The titanium alloy in this embodiment is specifically Ti-5Al-2.5Sn.

[0073] The coating method of the superhard friction-reducing and wear-resisting composite film layer on the surface of the titanium alloy in this embodiment specifically i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com