Aluminum and aluminum alloy normal-temperature environmental-friendly sealant and preparation method thereof

A technology of aluminum alloy and sealing agent, which is applied in the direction of electrolytic coating, surface reaction electrolytic coating, coating, etc., can solve the problems of long sealing time, slow sealing speed of sealing agent, weak permeability of sealing agent, etc., and achieve sealing The effect of high hole quality, increased hardness, and no harm to the human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Aluminum and aluminum alloy room temperature environment-friendly sealing agent of the present invention, the raw material of this sealing agent is counted as: sealing salt, 10g; Oxidant, 1.5g; Stabilizer, 2g; Accelerator, 6g; Wetting agent, 3g; pH buffer agent, 15g; deionized water, the amount added is the amount that the rest of the raw materials are mixed and then added with deionized water to make up to 1L.

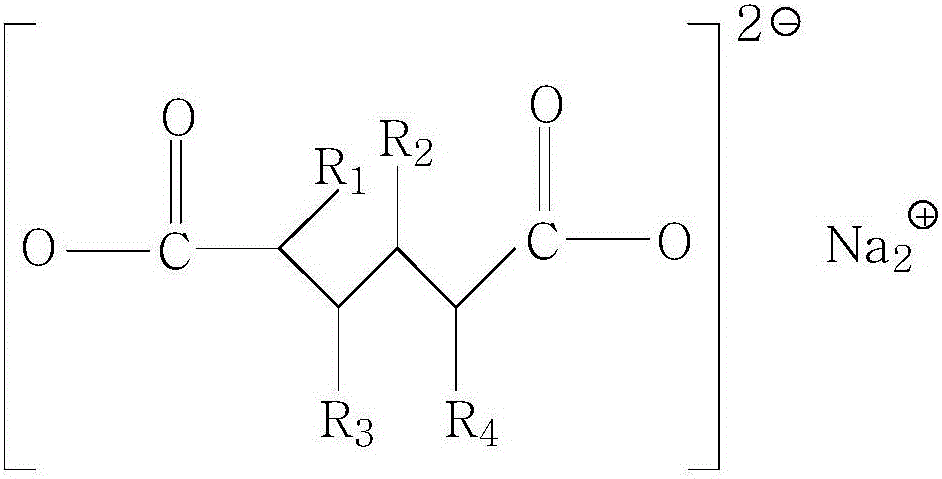

[0047] In the present embodiment, the sealing salt includes 4g yttrium chloride and 6g cerium acetate, the oxidant is potassium permanganate, and the stabilizer is a carboxylate derivative. The molecular structural formula is:

[0048]

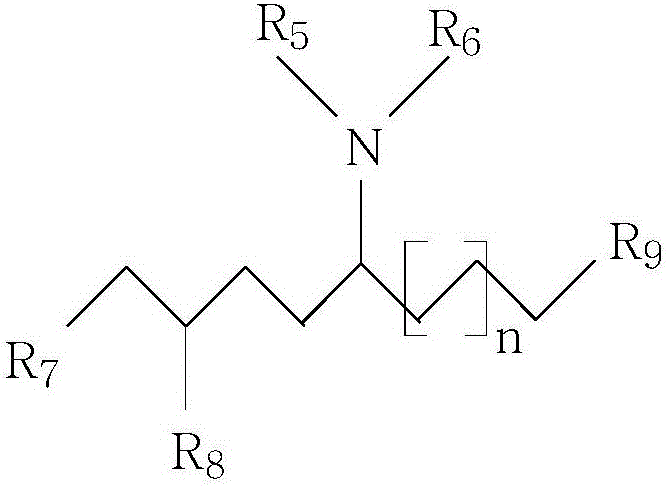

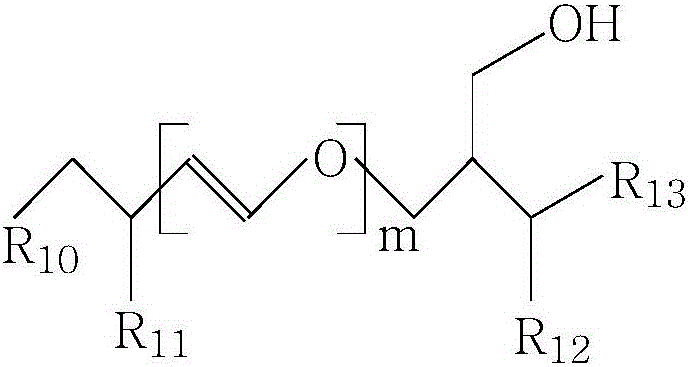

[0049] R in the molecular formula 1 is a hydrogen atom, R 2 is hydroxyl, R 3 is the amino group, R 4 is a methyl group; the accelerator is an aliphatic derivative, and the molecular structure formula is:

[0050]

[0051] R in the molecular formula 5 is hydroxyethyl, R 6 is hydroxyethyl, R 7 is amino, R 8 is methy...

Embodiment 2

[0062] Compared with Example 1, the aluminum and aluminum alloy room-temperature environment-friendly sealant of this example has no changes in the components, and only changes the proportion of the components.

[0063] The raw materials of the sealing agent in this example are calculated in 1L: sealing salt, 20g; oxidant, 0.5g; stabilizer, 0.3g; accelerator, 0.2g; wetting agent, 0.2g; pH buffer, 2g; Water, the amount to add is the amount that the rest of the raw materials are mixed and then added with deionized water to make the volume to 1L.

[0064] In the present embodiment, the sealing salt includes 8g yttrium chloride and 12g cerium acetate, the oxidant is potassium permanganate, and the stabilizer is a carboxylate derivative. The molecular structural formula is:

[0065]

[0066] R in the molecular formula 1 is a hydrogen atom, R 2 is hydroxyl, R 3 is the amino group, R 4 is a methyl group; the accelerator is an aliphatic derivative, and the molecular structure f...

Embodiment 3

[0078] Compared with Example 1, the aluminum and aluminum alloy room-temperature environment-friendly sealant of this example has no changes in the components, and only changes the proportion of the components.

[0079] The raw materials of the sealing agent in this embodiment are calculated by 1L: sealing salt, 15g; oxidizing agent, 1g; stabilizer, 1.15g; accelerator, 3.1g; wetting agent, 1.6g; pH buffering agent, 8.5g; Water, the amount to add is the amount that the rest of the raw materials are mixed and then added with deionized water to make the volume to 1L.

[0080] In the present embodiment, the sealing salt includes 6g yttrium chloride and 9g cerium acetate, the oxidant is potassium permanganate, and the stabilizer is a carboxylate derivative. The molecular structural formula is:

[0081]

[0082] R in the molecular formula 1 is a hydrogen atom, R 2 is hydroxyl, R 3 is the amino group, R 4 is a methyl group; the accelerator is an aliphatic derivative, and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com